Aluminum Sheets Oklahoma - AA8XXX Mill-Finished Aluminum Sheets for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA8xxx Mill-Finished Aluminum Sheets Used for Construction Description

AA8xxx Mill-Finished Aluminum Sheets Used for Construction is cut from aluminum coils 8xxx. The aluminum content of aluminum sheets 1xxx C.C quality is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA8xxx Mill-Finished Aluminum Sheets Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of AA8xxx Mill-Finished Aluminum Sheets Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

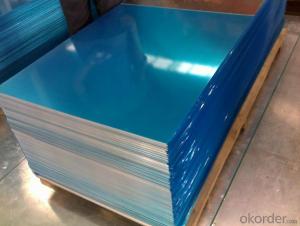

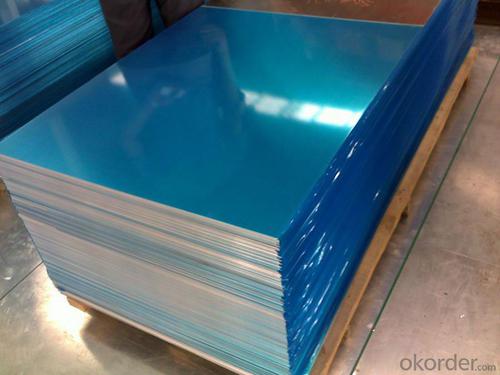

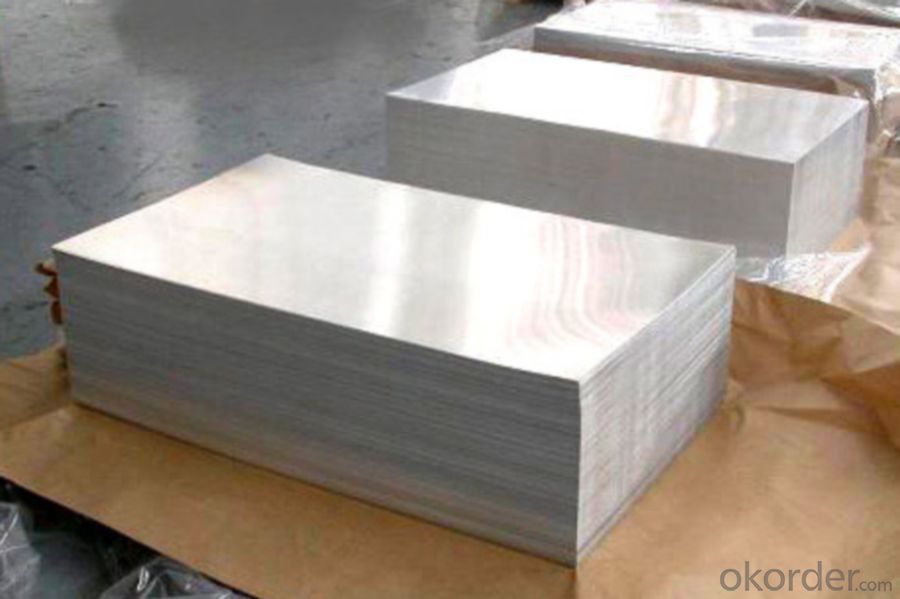

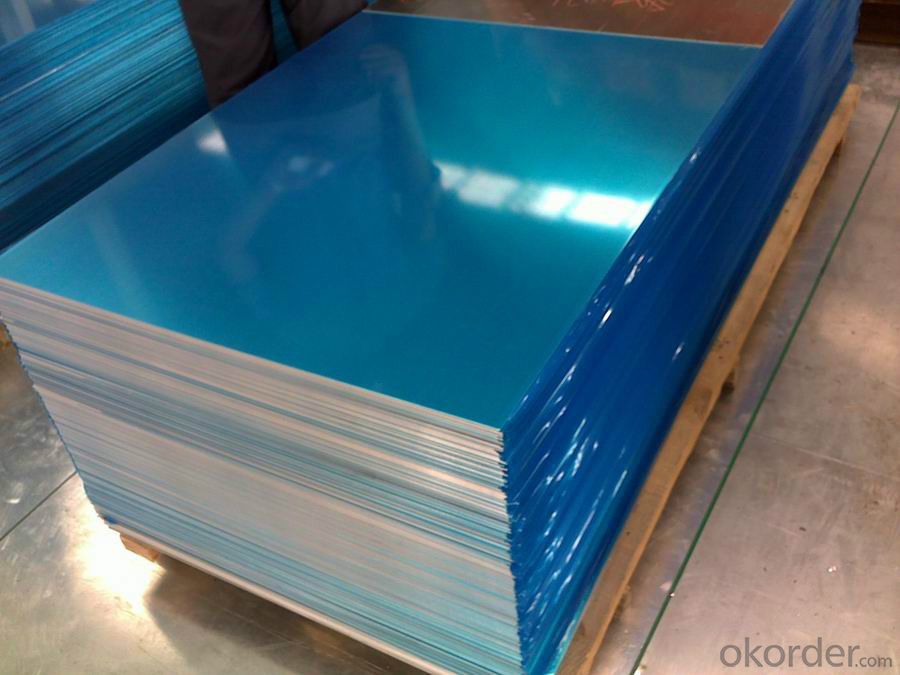

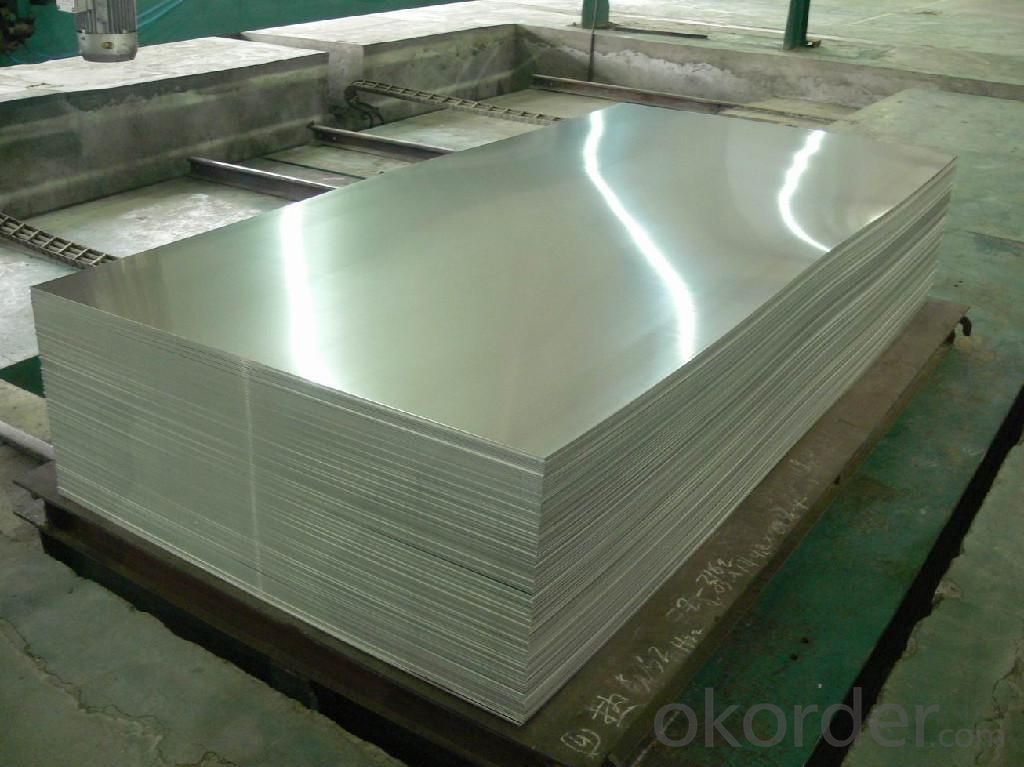

3.AA8xxx Mill-Finished Aluminum Sheets Used for Construction Images

4.AA8xxx Mill-Finished Aluminum Sheets Used for Construction Specification

Alloy | AA8xxx (AA5754,AA5083 etc) |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA8xxx Mill-Finished Aluminum Sheets Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA8xxx Mill-Finished Aluminum Sheets Used for Construction.

B.When will you deliver the products?

AA8xxx Mill-Finished Aluminum Sheets Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: Can anyone tell me what to be careful of if you have aluminum wiring in your house. I was told that if the wall gets hot, I need to tighten the screws of the inside switch. Is this true and if I didn't, would it actually cause a fire in the wall. If this is true, how often does it loosen?

- Aluminum wiring contracts and expands more than copper wiring of similar size. This means that it has a tendancy to loosen the screws on the outlets over time. As the screws loosen, the resistance in the circuit goes up - this resistance manifests itself as heat. If it gets too hot, it can start fires. My parents owned a house with aluminum wiring, that they sold to me. In the 35 years total we've owned it, I think we've tightened the screws on the outlets three times total. Only once in all that time have we had a wall get hot. The most recent tightening was during a major repainting where we actually replaced the outlets and switches with decorator ones as we painted each room.

- Q: Are aluminum sheets suitable for aerospace engine components?

- Aerospace engine components can indeed be made from aluminum sheets. Aluminum is widely employed in the aerospace industry because of its advantageous properties. Its lightweight nature is crucial for aircraft and spacecraft applications, as it aids in reducing overall weight and fuel consumption. Furthermore, aluminum possesses outstanding thermal conductivity, enabling efficient heat dissipation generated by the engine. This characteristic is essential for maintaining optimal operating temperatures. Additionally, aluminum exhibits a commendable strength-to-weight ratio, corrosion resistance, and ease of fabrication. These qualities make it suitable for various engine components like casings, housings, and structural elements. Nevertheless, it is important to note that not all engine components can be solely constructed using aluminum sheets. Certain parts may require higher strength materials or specific alloys to withstand extreme temperatures or stresses. Overall, aluminum sheets have proven to be a reliable and frequently employed material for aerospace engine components. They significantly contribute to the overall performance and efficiency of aerospace engines.

- Q: This question asks for precautions or methods to protect aluminum sheets from damage during the installation process.

- <p>To ensure that the installation process does not damage aluminum sheets, follow these steps: Use protective gloves to avoid scratches from hand oils or dirt. Employ non-marring tools to prevent any indentations or marks. Handle the sheets carefully to avoid bending or denting. Keep the surface clean and dry to prevent any chemical reactions or stains. Use appropriate support structures to distribute weight evenly and prevent warping. Always follow the manufacturer's guidelines for installation to avoid any improper handling that could lead to damage. Regularly inspect the sheets for any signs of damage during the installation process and address any issues promptly.</p>

- Q: Do 101 aluminum sheets have any specific certifications or standards?

- Yes, 101 aluminum sheets typically have certifications and standards that ensure their quality and performance. These may include certifications like ASTM (American Society for Testing and Materials) and standards such as AA (Aluminum Association) standards, which verify the material's composition, mechanical properties, and manufacturing processes. Additionally, specific industry certifications like ISO 9001 (International Organization for Standardization) may be applicable to ensure consistent quality control during production.

- Q: i heard that aluminum causes Alzheimers and i was wondering if there is any aluminum in tin.

- Tin is an element, so there isn't anything else in tin. However, tin, the element, isn't really used for much as *just* tin. Tin foil is really a mixture of tin and aluminimum, tin cans aren't pure tin. As elements go, tin is pretty rare. As for the Alzheimers, they don't really know what the correlation is; but they have found large accumulations of metals, not only aluminum, but it doesn't show that causes it. The expression ad hoc, ergo, procter hoc means, before, therefore it caused it. What I mean here is that just because they have found accumulations of aluminum in the brains of Alzheimer's, it doesn't mean it caused it any more than the fact that I did laundry this morning, caused me to spill my coffee on my husband. (both true). Just becasue they happened in that order doesn't mean A caused B. It could mean that whatever causes alzheimers could also mean that the brains of people suspectible to it have a greater ability to accumulate metals crossing the blood-brain barrier. We just don't know enough. I get porcelian caps on my teeth because they thought silver amalgam fillings was causing dementia. Hope I helped~

- Q: Can aluminum sheet be used for food packaging?

- Yes, aluminum sheet can be used for food packaging. Aluminum is a popular choice for food packaging due to its unique properties. It is lightweight, flexible, and has excellent barrier properties that protect the food from moisture, oxygen, and light. This helps to extend the shelf life of the products and maintain their freshness. Aluminum sheet is commonly used for packaging various food items such as beverages, snacks, dairy products, and ready-to-eat meals. Additionally, aluminum is non-toxic and does not react with food, making it safe for direct contact with consumables. Its ability to be easily formed into different shapes and sizes also makes it suitable for various packaging requirements. Overall, aluminum sheet is a reliable and widely used material for food packaging due to its durability, protective properties, and safety standards.

- Q: Are 101 aluminum sheets suitable for outdoor applications?

- Indeed, outdoor applications can benefit from the suitability of 101 aluminum sheets. This alloy, widely favored, boasts exceptional resistance to corrosion, rendering it an optimal choice for outdoor settings frequently subjected to moisture, sunlight, and similar factors. Moreover, 101 aluminum exhibits solid strength and durability, enabling it to endure diverse weather conditions and physical strains. As a result, it finds extensive use in outdoor projects, including siding, roofing, gutters, and outdoor signage.

- Q: Can aluminum sheet be used for decorative purposes?

- Yes, aluminum sheet can be used for decorative purposes. Aluminum is a versatile material that can be easily shaped, cut, and formed into various designs, making it ideal for decorative applications. It can be used to create decorative panels, sculptures, signage, furniture, and many other decorative elements. Additionally, aluminum can be anodized or painted in a wide range of colors, allowing for further customization and enhancing its aesthetic appeal. Its lightweight nature and resistance to corrosion also make it a practical choice for both indoor and outdoor decorative purposes.

- Q: I'm buying a sword this afternoon for about 100 bucks i'm using it mainly to take pictures of and hang it on my wall. I looked up tips about buying swords and i think the sword i want is made out of aluminum. Could i use this sword as protection on an armed robber who would break into my house?

- Aluminum okorder /... Read both pages. The information is basic enough to be useful no matter where you live.

- Q: Are the aluminum sheets suitable for manufacturing audio speaker enclosures?

- Indeed, the utilization of aluminum sheets is appropriate for the fabrication of audio speaker enclosures. Aluminum, being a lightweight and sturdy substance, is frequently employed in the manufacturing of speaker enclosures. It possesses exceptional acoustic characteristics that enable the production of precise and clear sound reproduction. Furthermore, aluminum exhibits resistance to corrosion, thereby guaranteeing the enduring lifespan of the speaker enclosure. Moreover, aluminum can be effortlessly molded and shaped into diverse designs, providing flexibility throughout the manufacturing procedure. All in all, due to their acoustic properties, durability, and versatility, aluminum sheets are an appropriate selection for the production of audio speaker enclosures.

Send your message to us

Aluminum Sheets Oklahoma - AA8XXX Mill-Finished Aluminum Sheets for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords