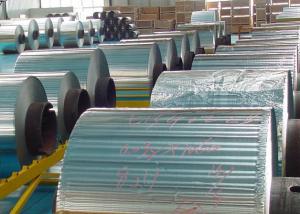

8011 Painted Aluminum Trailer Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of 8011 Aluminium Coils

|

Alloy |

AA8011 |

|

Temper: |

H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

|

Thickness: |

0.10-500mm |

|

Width: |

10mm- 2200mm |

|

Standard: |

GB/T3880-2006, ASTM, ISO, EU standard |

|

Special Specification is available on customer’s requirement | |

2. Applications of 8011 Aluminium Coils

8011 Aluminium Coils are widely used in househould field, package, cookware, construction, decoration, etc.

3. Package & Delivery of 8011 Aluminium Coils

Seaworthy package, water-proof paper wrapped inside, carton wrapped outside in wooden pallets by 20FCL or 40GP.

4. Production Flow of 8011 Aluminium Coils

The main producingprocedure includes the following steps:

Rolling--Annealing--Slitting--Sawing, Cut-To-Length, Shearing

- Q: how many aluminum ions are present?how many chloride ions are present?what is the mass in grams of one molecule of aluminum chloride?help! i have no clue how to do this i need to know how for my quiz!!!

- You have to remember Avogadro's number: 6.02 x 10^23 Read about it in your text book. It is the number of molecules of any atom that make up 1 mole. 1 mole of a molecule is equal to it's atomic weight in grams. So, the atomic weight of aluminum is 26.9. So, 26.9 grams of aluminum contains exactly 6.02 x 10^23 molecules of aluminum (or 1 mole). What's the molecular weight of aluminum chloride? Well, 26.9 + 3(35.5) = 133.4 the 35.5 is the molecular weight of chloride and there are 3 of them. So, 133.4 grams of aluminum chloride would be 6.02 x 10^23 molecules. We only have 37.2 g. 37.2 g/ 133.4 g per mole = 0.279 moles. 0.279 moles x (6.02 x 10^23 molecules/mole) = 1.68 x 10^23 molecules of aluminum chloride. So, since there is one aluminum per molecule, you have your answer. Just multiply by three to find out how many molecules of chloride are present. Finally, if 133.4g = 6.02 x 10^23 molecules, then 1 molecule = 133.4 / 6.02x10^23 = 22.16 x 10^-23 or 2.216 x 10^-22 Make sure that the periodic table you use for class has the same values (some tables are more simplified then others). Also, make sure that you use the correct number of scientific digits when calculating your answer.

- Q: What are the different methods of surface treatment for aluminum sheets?

- Aluminum sheets can undergo various surface treatment methods, each with its own purpose and desired outcome. Popular methods include anodizing, chromate conversion coating, painting, and powder coating. Anodizing is commonly used to enhance the corrosion resistance and durability of aluminum sheets. This involves immersing the sheets in an electrolytic bath and applying an electric current to create a controlled oxide layer on the surface. The result is a protective and decorative coating that can be colored or sealed. Chromate conversion coating, also known as chemical conversion coating or chromating, applies a thin layer of chromate to the aluminum sheets. This method provides excellent corrosion resistance and improves paint adhesion. The coatings can be clear or have a yellowish or iridescent appearance. Painting is a widely used method to protect aluminum sheets and improve their visual appeal. Sheets are typically pre-treated with a primer to enhance adhesion, followed by the application of a topcoat for protection and color. Painted aluminum sheets come in a wide range of colors and finishes, suitable for various applications. Powder coating is an environmentally friendly and durable surface treatment for aluminum sheets. It involves electrostatically applying a dry powder onto the sheets, which is then cured in an oven. The powder melts and fuses to form a tough and attractive coating. Powder coating offers excellent resistance to corrosion, chemicals, and UV radiation. In addition to these methods, other techniques like polishing, buffing, and mechanical finishes can be employed to achieve specific desired appearances or surface qualities. Ultimately, the choice of surface treatment method for aluminum sheets depends on factors such as desired corrosion resistance, aesthetic requirements, environmental considerations, and the intended application of the sheets.

- Q: Are aluminum sheets suitable for insulation and soundproofing?

- No, aluminum sheets are not suitable for insulation and soundproofing as they are not effective in blocking heat transfer or sound waves.

- Q: What is the cost of aluminum sheets?

- The cost of aluminum sheets can vary depending on factors such as size, thickness, and quantity. It is best to check with suppliers or retailers for current pricing information.

- Q: The question asks if it is possible to recycle used aluminum foil to create new aluminum sheets.

- <p>Yes, recycled aluminum foil can be used to make new aluminum sheets. The process involves collecting and sorting the foil, which is then cleaned and melted down. The molten aluminum is poured into molds or rolled into sheets, creating new aluminum products. This recycling method is not only environmentally friendly but also economically viable as it saves energy compared to producing aluminum from raw materials.</p>

- Q: How does the price of 101 aluminum sheets compare to other aluminum alloys?

- The price of 101 aluminum sheets is typically lower compared to other aluminum alloys.

- Q: when aluminum metal undergoes a combination reaction with O2(g)

- Aluminium metal combines with the oxygen from the air on heating to form aluminium oxide. The reaction can be represented using a balanced equation as 4 Al (s) + 3O2(g) = 2Al2O3(s)

- Q: What is the typical thermal expansion coefficient of aluminum sheets?

- Aluminum sheets generally possess a thermal expansion coefficient of approximately 23.1 x 10^-6 per degree Celsius. Consequently, with each degree Celsius rise in temperature, the length of an aluminum sheet will expand by roughly 23.1 millionths of its initial length. However, it should be acknowledged that this figure might slightly differ based on the particular alloy and processing circumstances of the aluminum sheet.

- Q: Hi guys. I was just wondering if you can give me some tips or information on what you know about painting on metal. The metal that is of concern is aluminium and I would like to put a stencil over this aluminium and just blast it with a can of krylon. Of course...this aluminium piece is actually part of the housing for my cell phone so doing it like this would probably not be right and the paint would probably wear out. I am mainly interested in finding out what kind of paint to use, what tools i need, and how to achieve an extremely! durable! matte finish because this phone is thrown around and going in and out of my pocket the paint will have to withstand getting rubbed down everyday by my pockets.That was a very long question, thanks for bearing with me and thanks in advance for those who provided me with an answer/thought. THANKS!

- Discover Spray Paint Art Secrets!

- Q: What are the advantages of using aluminum sheets?

- Aluminum sheets offer numerous benefits for various applications. To begin with, their lightweight nature makes them easy to transport and handle. This makes them particularly suitable for industries where weight plays a crucial role, such as aerospace and automotive sectors. Moreover, aluminum sheets possess exceptional corrosion resistance properties. They have a natural resistance to rust and can endure harsh environmental conditions, including moisture, chemicals, and UV rays. As a result, they are highly durable and long-lasting, reducing the need for frequent maintenance and replacements. Additionally, aluminum sheets are highly malleable and can be easily shaped into different forms and sizes. This flexibility allows for customization and versatility in design, enabling manufacturers to create intricate structures and products. Furthermore, aluminum sheets exhibit remarkable thermal and electrical conductivity. They effectively dissipate heat and conduct electricity, which makes them well-suited for applications in the electrical, heating, and cooling industries. Another advantage of utilizing aluminum sheets is their aesthetic appeal. Aluminum has a sleek and contemporary appearance, making it a popular choice for architectural and interior design projects. It can be effortlessly painted or coated to achieve various colors and finishes, further enhancing its visual allure. Lastly, aluminum is a sustainable material. It is fully recyclable and can be repeatedly melted and reformed without losing its properties. This makes aluminum sheets an environmentally friendly option, contributing to waste reduction and a lower carbon footprint. In conclusion, the advantages of employing aluminum sheets include their lightweight nature, corrosion resistance, malleability, thermal and electrical conductivity, aesthetic appeal, and sustainability. These qualities make aluminum sheets the preferred material for numerous industries and applications.

1. Manufacturer Overview

| Location | Henan,China |

| Year Established | 2002 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

8011 Painted Aluminum Trailer Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords