Cargo Trailer Aluminum Sheets 8xxx Mill Finished

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 tons m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Sheets 8xxx Mill Finished Description:

Aluminum sheets 8xxx mill finished is cut from aluminum coils 8xxx. Aluminum sheets 8xxx mill finished have great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum sheets 8xxx mill finished is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of the Aluminum Sheets 8xxx Mill Finished:

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

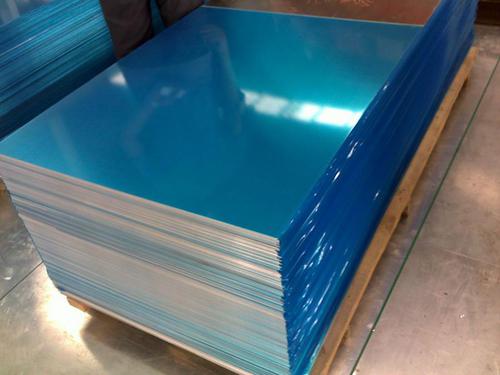

3.Aluminum Sheets 8xxx Mill Finished Images

4.Aluminum Sheets 8xxx Mill Finished Specification

| Alloy | AA8xxx (AA8011, AA8006 etc) |

| Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

| Thickness | 0.2mm--100mm |

| Width | 30mm--1700mm |

| Standard | GB/T 3880-2006 |

5. FAQ of Aluminum Sheets 8xxx Mill Finished

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test the aluminum sheets 8xxx mill finished products.

B. What is the MOQ?

The MOQ of aluminum sheets 8xxx mill finished is 7-8 tons for each size.

- Q: I have an aluminum block engine in my wakeboard boat which is built for the lakes, now i live on salt water and was wondering the effect saltwater would have on the engine block as water goes through to cool it.

- it will eat it up... install a heat exchanger

- Q: What is the cost of aluminum sheet compared to other metals?

- The cost of aluminum sheet compared to other metals can vary depending on various factors such as market conditions, availability, and specific metal grades. Generally, aluminum sheet is considered to be more affordable than many other metals such as stainless steel, copper, and brass. This is mainly due to the abundance of aluminum in the Earth's crust and the relatively low cost of extracting and refining it. Additionally, aluminum is often lighter in weight compared to other metals, making it a more cost-effective option for applications where weight is a concern, such as in the transportation industry. However, it is important to note that the cost of aluminum can fluctuate based on global supply and demand dynamics, tariffs, and other economic factors. Therefore, it is recommended to check current market prices and consult with suppliers or metal specialists for accurate and up-to-date pricing information.

- Q: how to produce aluminium sheet circle?

- As for the process, you can use punch.. as for professional machines, for example, stationary press in open type, mechanical press/ single-point press. The material you say is neither big nor small, blanking…(cutting them into sheet circle you want) you can add an uncoiling if it’s coil stock: open-type inclinable press, four-point press,ect. It’s not certainly accurate) punch, oil press, double , four-column hydraulic (oil) press,etc. it needs about 315T,(estimated value, closed type single, blank material cutting (cutting into square ) 2, it contains sheet metal forming technology, crank press: 1: straight side two : 1, but the components you said is simple, only two steps.

- Q: why can aluminum sheet after oxide film removal react quicker with hydrochloric acid?

- the reason is very simple, the original aluminum sheet has a layer of dense oxide film AI2O3, which has prevented the inner aluminum sheet from reacting with hydrochloric acid. but after oxide film removal, aluminum sheet will directly contact hydrochloric acid, generating H2.

- Q: what is better for my 96 mustang gt. porting and polishing my stock heads or getting aluminum heads. also could i do a 3v conversion?

- It is hard to beat a set of CNC machined new heads. By the time you pay the machining amd parts cost you may be money ahead to buy the new heads.

- Q: Can aluminum sheets be used for signage?

- Yes, aluminum sheets can be used for signage. Aluminum is a versatile material that is durable, lightweight, and weather-resistant, making it suitable for outdoor and indoor signage applications. It can be easily customized, cut, and shaped to create various types of signage, including signs for businesses, roadways, and informational displays.

- Q: Are aluminum sheets suitable for use in marine or saltwater environments?

- Yes, aluminum sheets are suitable for use in marine or saltwater environments. Aluminum has excellent corrosion resistance properties, making it a popular choice for marine applications. It forms a protective oxide layer that prevents further corrosion, making it durable and long-lasting in saltwater environments.

- Q: This question asks for a list of various types of fasteners that can be used to secure aluminum windows to their frames.

- <p>There are several types of fasteners used for attaching aluminum windows to frames, including: 1. Screws: Commonly used for their secure hold and ease of installation. 2. Nails: Quick to use but may not provide the same level of security as screws. 3. Adhesives: Can be used for a more permanent bond, especially in certain applications. 4. Clips and brackets: Used for a more visible, decorative attachment. 5. Rivets: Provide a strong, permanent connection but are not easily removable. 6. Dowels and pins: Used for a more traditional or decorative join. 7. Structural glazing systems: Employ silicone or other sealants to bond the window to the frame. Each type of fastener has its own advantages and is chosen based on the specific requirements of the project, such as load-bearing needs, aesthetic considerations, and the desired level of permanence.</p>

- Q: Can aluminum sheets be used in construction?

- Yes, aluminum sheets can be used in construction. They are commonly used for roofing, siding, and structural applications due to their lightweight, corrosion-resistant, and durable properties.

- Q: Are 101 aluminum sheets suitable for food-grade applications?

- Indeed, 101 aluminum sheets prove to be fitting for food-grade applications. 101 aluminum, being a commercially pure alloy, exhibits remarkable resistance against corrosion and possesses commendable formability. Its low chemical reactivity ensures that it remains unresponsive to acidic or alkaline substances, thus rendering it secure for usage in food-grade applications. Furthermore, the convenience of effortlessly cleaning and sanitizing 101 aluminum sheets designates them as an optimal selection for food processing, packaging, and storage purposes.

Send your message to us

Cargo Trailer Aluminum Sheets 8xxx Mill Finished

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 tons m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords