Aluminum Strips Menards - AA 3004, 3105, 5006, 5052, 8011 Color Coated Aluminium Sheet for Trailers

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

1) Alloy : 1050 1060 1070 1100 2024 3003 3004 3105 3A21 5005 5052 5083 5754 5182 5454 5456 6061 6063 7075 8011 etc

2)Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.18mm to 350mm

4) Width: 200mm to 2300mm

5)Length: no more than 12000mm

6) Protective film can be added

7) Production Line: DC and CC production line

3. Feature of Aluminum

Aluminium is almost always alloyed, which markedly improves its mechanical properties, especially when tempered. For example, the common aluminium foils and beverage cans are alloys of 92% to 99% aluminium. The main alloying agents are copper, zinc, magnesium, manganese, and silicon (e.g., duralumin) and the levels of these other metals are in the range of a few percent by weight.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

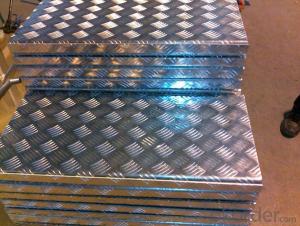

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Explain the distinctions between aluminum sheets and aluminum strips.

- <p>Aluminum sheets and aluminum strips are both flat aluminum products, but they differ in width and thickness. Aluminum sheets are wider and can range from 0.2mm to 500mm in thickness, suitable for applications requiring broad surfaces like construction and packaging. Aluminum strips, on the other hand, are narrower and typically used in applications that require thin, elongated pieces, such as in electrical conduits or mechanical parts. The production processes may also vary, with sheets often being rolled and strips being extruded or rolled as well, depending on the specific application and desired properties.</p>

- Q: 25 square metres of aluminium wire. Can you bring up 4 sets of two air conditioners?

- Temporary use, no problem.Aluminum wire easy oxidation aging, it is recommended copper wire.

- Q: Is it possible to use aluminum strips as a material for roofing purposes?

- <p>Yes, aluminum strips can be used for roofing. They are known for their durability, corrosion resistance, and lightweight properties, making them a popular choice for metal roofing. Aluminum roofing strips are low maintenance, energy-efficient, and can be recycled, offering environmental benefits. They are also resistant to harsh weather conditions and can last for several decades with proper installation and care.</p>

- Q: The user is inquiring if it's possible to use recycled paints or coatings to prevent rust and corrosion on aluminum strips.

- <p>Yes, you can use recycled paints or coatings to protect aluminum strips from rusting or corrosion. However, it's important to ensure that the recycled paints are compatible with aluminum and offer sufficient protection. Recycled paints should be free from contaminants that could compromise the protective layer. Additionally, the application process should be done correctly to ensure an even and effective coating. It's also recommended to test a small area first to verify the effectiveness of the recycled paint or coating before applying it to the entire surface of the aluminum strips.</p>

- Q: This question asks for a comparison between aluminum strips and other roofing materials in terms of their characteristics and performance.

- <p>Aluminum strips are lightweight and highly durable, offering excellent resistance to corrosion and weathering. They are low-maintenance and have a long lifespan, often outlasting other materials like asphalt shingles. Compared to metal roofing, aluminum strips may be more prone to denting, but they are quieter and less likely to expand or contract with temperature changes. When compared to tile or slate, aluminum is much lighter, reducing the load on the structure and installation costs. However, it may not offer the same aesthetic appeal or insulation properties. Overall, aluminum strips are a cost-effective and eco-friendly choice for roofing, especially in areas with harsh weather conditions.</p>

- Q: Can welding of aluminum with water-cooled DC hydrogen arc welding machine how much money

- Cheapest 3 million, slightly better, such as Panasonic's ten thousand or twenty thousand

- Q: Is it possible to apply paint to aluminum strips?

- <p>Yes, aluminum strips can be painted. However, proper surface preparation is crucial for good adhesion and durability of the paint. This typically involves cleaning the aluminum to remove any grease or contaminants, followed by etching or using a primer designed for aluminum to promote better paint adherence. After priming, the aluminum can be painted with a suitable paint, such as acrylic or epoxy, which are known for their compatibility with metal surfaces. It's important to follow the manufacturer's instructions for the specific paint and primer used to ensure the best results.</p>

- Q: What benefits can be gained from using aluminum strips as a siding material for buildings?

- <p>Aluminum strips for siding offer several advantages, including durability, low maintenance, and resistance to rust and corrosion. They are lightweight, which makes installation easier and quicker. Aluminum siding is also energy-efficient, as it can help to insulate a building, reducing energy costs. Additionally, it is recyclable and environmentally friendly, contributing to sustainability efforts. The material is available in a wide range of colors and styles, allowing for great flexibility in design. It is also resistant to harsh weather conditions, making it a popular choice for various climates.</p>

- Q: Is it possible to install aluminum siding on a historic building without compromising its aesthetic or structural integrity?

- <p>Using aluminum siding on a historic building can be done without damaging its appearance or structure if done correctly. It's crucial to ensure that the siding is installed in a manner that respects the building's historical integrity. This often means using siding that closely matches the original materials in terms of color and texture, and installing it in a way that doesn't alter the building's structural elements. Consulting with historic preservation experts and adhering to local preservation guidelines is essential to maintain the building's historic character while providing the benefits of modern siding materials.</p>

- Q: This question asks for a step-by-step guide on how to attach aluminum strips to a roof or wall.

- <p>To install aluminum strips on a roof or wall, follow these steps: 1. Measure and mark the area where the strips will be installed. 2. Clean the surface thoroughly to ensure proper adhesion. 3. Cut the aluminum strips to the required length using a hacksaw or tin snips. 4. Apply a bead of construction adhesive along the top edge of the strip. 5. Press the strip firmly into place, starting from one end and working your way along the surface. 6. Use a level to ensure the strip is straight and secure it with nails or screws at regular intervals. 7. Fill any gaps between the strips and the surface with caulk to create a watertight seal. 8. Finish with a coat of paint or sealant to match the surrounding area and protect the aluminum from weathering. Always follow the manufacturer's instructions for the specific adhesive and sealant products you are using.</p>

Send your message to us

Aluminum Strips Menards - AA 3004, 3105, 5006, 5052, 8011 Color Coated Aluminium Sheet for Trailers

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords