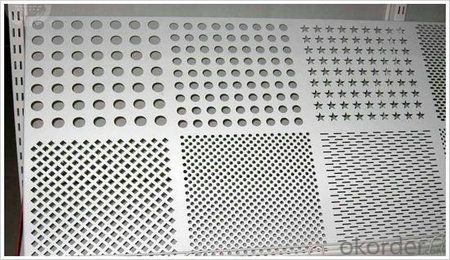

8011 Grade DC&CC Aluminum Perforated Sheets - China Aluminum Coil Plate Aluminum Sheet Stocks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Common Aluminum Sheet Coil

1. Place of Origin: ZheJiang, China (Mainland)

2. Model Number: 1050/1060/3003/3004/5052/8011

3. Thickness: 0.20-20.0 mm

4. Width: 1000-1700 mm

Packaging & Delivery

1. Coating: Wooden Pallet for Exporting

2. Delivery Detail: 25-30 Days

Specifications

Aluminum Sheet

1. Alloy: 3003A1050/1060/3003/3004/5052/8011

3. Thickness (mm): 0.20-20.0

4. Width (mm): 1000 mm to 170 0mm, Customer Specific Width

5. Finish: Mill, Customer Specific Finish

Our main products are aluminum alloy thick sheet

PS/CTP plate (1050)

anodic oxidation / 3003/5052 (1060/1070)

automotive aluminum alloy (5754/6111/6061)

soldering material (3003/4004)

IT used materials (3003/5052)

the LED base material, material can (3004/3104)

the tank cover and TAB (5052/5182)

aluminous model with substrate (1100)

medicinal foil (8011)

household foil aluminum foil (1235) (8011)

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

- Q: Does aluminum sheet require special handling during transportation?

- Yes, aluminum sheets typically require special handling during transportation. This is because aluminum is a lightweight yet fragile material that can easily dent, scratch, or bend. To prevent such damages, it is important to handle aluminum sheets with care, avoiding rough handling, excessive bending, or stacking heavy objects on top. Additionally, protective measures like using padding or wrapping the sheets in protective material can help ensure their safe transportation.

- Q: How do you prevent galvanic corrosion when using aluminum sheets with concrete?

- To prevent galvanic corrosion when using aluminum sheets with concrete, it is essential to use a barrier or protective coating between the aluminum and concrete surfaces. This can be achieved by applying a suitable paint, epoxy coating, or a non-conductive membrane to isolate the aluminum from direct contact with the concrete. Additionally, using corrosion-resistant fasteners made of stainless steel or other compatible materials can further prevent the occurrence of galvanic corrosion. Regular inspections and maintenance are also crucial to identify and address any potential corrosion issues promptly.

- Q: Can aluminum sheets be used for electrical conductors?

- Aluminum sheets have the capability to function as electrical conductors. Despite being less efficient than copper, aluminum demonstrates good electrical conductivity. Nevertheless, owing to its lightweight properties, affordability, and resistance to corrosion, aluminum is frequently employed in various electrical applications. It finds extensive use in power distribution lines, wiring systems, and electrical equipment.

- Q: This question asks for a comparison of the benefits and drawbacks of using aluminum sheets as a roofing material.

- <p>Aluminum sheets for roofing offer several advantages, including durability, resistance to rust and corrosion, lightweight nature, and energy efficiency due to reflective properties. They are also easy to install and maintain, and can be recycled, making them environmentally friendly. However, there are some disadvantages such as being more expensive than some other roofing materials, potential for denting if not properly installed, and noise issues during heavy rain or hail due to their lightweight nature. Additionally, they may require more frequent replacement compared to some other materials.</p>

- Q: What is the difference between aluminum plate and aluminum-plastic plate?

- Simply put, aluminum plate is pure metal, aluminum plate is only the surface of metal (surface metal processing), and the middle is polyethylene plastic.In the same thickness and specifications, the aluminum plate is heavier than the aluminum-plastic plate, and the price is generally higher than that of the aluminum plate. 2.5mm aluminum plate to see, polyester or fluorocarbon, aluminum material, machining drawings, are often n flat at around 250, aluminum plate, aluminum depends on the thickness of the plastic type and so on normal inner wall 40 yuan a square, 100 yuan per square wall aluminum plate and aluminum plate installation is a kind of the aluminum is only good processing and molding to the site, and then to the site after the aluminum plate molding, aluminum plate manufacturer's website will generally some. There are also some details please consult the steel E station through

- Q: This question asks for methods to maintain and repair aluminum sheets once they have been installed.

- <p>To maintain and repair aluminum sheets after installation, follow these steps: Regularly clean the surface with a soft cloth and mild detergent to remove dirt and grime. Avoid abrasive materials that can scratch the surface. For minor scratches or dents, use aluminum filler or touch-up paint that matches the sheet's color. Apply the filler or paint carefully, following the manufacturer's instructions. For more severe damage, consider hiring a professional to assess and repair the damage to ensure structural integrity. Always check for any signs of corrosion and address them promptly to prevent further damage. Regular maintenance will prolong the life of aluminum sheets and keep them looking their best.</p>

- Q: This question asks about the energy savings achieved by using aluminum sheets in comparison to other materials.

- <p>The energy savings achieved by using aluminum sheets instead of other materials can be significant. Aluminum is lightweight and has excellent thermal conductivity, which means it can reduce energy consumption in applications like building insulation and heat exchangers. For instance, aluminum-framed buildings can save up to 40% more energy than those made with traditional materials due to better insulation properties. Additionally, in industrial processes, aluminum's high thermal conductivity can lead to energy savings of around 33% compared to using copper in heat exchangers. The exact amount of energy saved depends on the specific application and the materials being replaced.</p>

- Q: What are the different methods of surface etching aluminum sheets?

- There are several methods of surface etching aluminum sheets, including chemical etching, electrochemical etching, mechanical etching, and laser etching. Chemical etching involves the use of corrosive chemicals to selectively remove the surface material, creating a desired pattern or design. Electrochemical etching uses an electrical current to dissolve the surface of the aluminum sheet, also creating a pattern. Mechanical etching involves physically abrading the surface using tools or abrasive materials. Laser etching utilizes a high-powered laser beam to selectively remove the aluminum material, creating precise and detailed patterns.

- Q: Do the aluminum sheets come with a protective coating?

- Yes, the aluminum sheets come with a protective coating.

- Q: Is it feasible to use aluminum sheets for constructing exteriors of buildings in regions susceptible to earthquakes?

- <p>Aluminum sheets can be used for building exteriors in earthquake-prone areas, but they must be properly engineered and installed. Aluminum is lightweight and flexible, which can be advantageous in withstanding seismic forces. However, it's crucial to ensure that the aluminum is reinforced with a robust structural system that can distribute the forces during an earthquake. The design must also comply with local building codes and seismic regulations. It's recommended to consult with structural engineers and architects experienced in earthquake-resistant design to ensure the safety and durability of the construction.</p>

Send your message to us

8011 Grade DC&CC Aluminum Perforated Sheets - China Aluminum Coil Plate Aluminum Sheet Stocks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords