Aluminum Strips Bunnings 8011 Grade DC&CC Aluminum Coil, Plate, Aluminum Sheet Stocks for Aluminum Foil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

Which he at first termed alumium and later aluminum (see etymology section, below).The metal was first produced in 1825 in an impure form by Danish physicist and chemist Hans Christian Ørsted. He reactedanhydrous aluminium chloride with potassium amalgam, yielding a lump of metal looking similar to tin.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

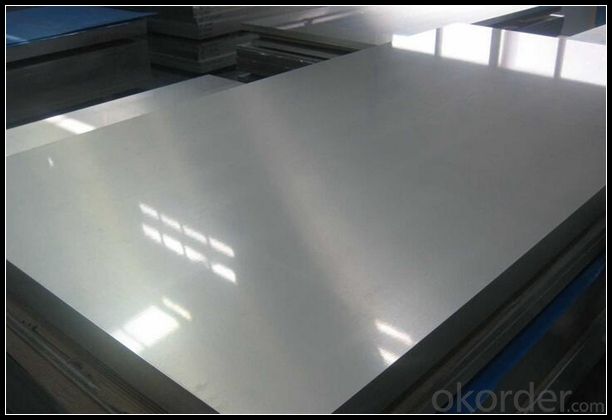

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: This question seeks to understand the distinctions between aluminum and copper as materials used for siding in construction.

- <p>Aluminum and copper siding differ in several ways. Aluminum is lightweight, corrosion-resistant, and requires minimal maintenance, making it a popular choice for durability and low cost. It is also available in a variety of colors and finishes. Copper, on the other hand, is heavier and more expensive, but it develops a natural patina over time, which can add a unique aesthetic appeal. Copper is also highly durable and recyclable, and it does not require painting. However, it is more prone to denting and can be more challenging to install. In terms of thermal performance, copper conducts heat better than aluminum, which can be an advantage in certain climates.</p>

- Q: Is it possible to use aluminum strips as a material for wall cladding?

- <p>Yes, aluminum strips can be used for wall cladding. They are lightweight, durable, and resistant to corrosion, making them suitable for both interior and exterior applications. Aluminum strips are also easy to install and maintain, and they can be painted or finished in various ways to match different architectural styles. However, it's important to ensure that the aluminum is of high quality and that the installation is done correctly to achieve a secure and aesthetically pleasing result.</p>

- Q: What types of aluminum alloys have higher tensile strength compared to others?

- <p>Yes, certain aluminum alloys exhibit superior tensile strength compared to others. For instance, 7075 aluminum alloy, known for its high strength, is often used in aerospace applications. It has a tensile strength of around 524 MPa. Another strong alloy is 2024, which is used in aircraft structures and has a tensile strength of about 425 MPa. These alloys achieve their strength through heat treatment and alloying elements like copper, magnesium, and zinc, which enhance their mechanical properties.</p>

- Q: What types of aluminum strips are better suited for specific uses?

- <p>Yes, different types of aluminum strips are more suitable for specific applications based on their properties. For instance, 1100 series aluminum strips are pure and have excellent formability, making them ideal for deep drawing applications. 3003 series strips are commonly used for chemical equipment, shipbuilding, and aircraft structures due to their good corrosion resistance and weldability. 5052 series strips are known for their high strength and are often used in marine applications and transportation vehicles. 6061 series strips are popular for structural applications requiring strength and good corrosion resistance, such as in the construction and automotive industries. The choice of aluminum strip depends on the specific requirements of the application, including strength, formability, corrosion resistance, and environmental factors.</p>

- Q: What are the potential dangers or issues that could arise from using adhesive to attach aluminum strips?

- <p>Using adhesive to install aluminum strips can involve certain risks. These include the possibility of the adhesive failing over time, leading to the strips becoming loose or falling off. There's also a risk of the adhesive damaging the surface it's applied to, especially if it's not removed carefully or if it's a sensitive material. Additionally, improper installation can lead to an uneven or unattractive finish. It's important to use a high-quality adhesive suitable for the material and follow the manufacturer's instructions to minimize these risks.</p>

- Q: Is it possible to utilize aluminum strips as a material for insulating interior walls?

- <p>Aluminum strips are not typically used for interior wall insulation. Insulation materials are designed to provide thermal resistance, and aluminum is a good conductor of heat, which makes it unsuitable for insulation purposes. Common insulation materials include fiberglass, mineral wool, and polyurethane foam, which are effective at reducing heat transfer. Aluminum strips might be used in construction for other purposes, such as reinforcement or as a vapor barrier, but not for insulation.</p>

- Q: Is it possible to utilize aluminum strips as materials for constructing roofs?

- <p>Yes, aluminum strips can be used for roofing materials. They are known for their durability, resistance to corrosion, and lightweight properties. Aluminum is also recyclable and can be coated with various finishes to enhance its appearance and performance. It is often used in modern architecture for its sleek look and low maintenance requirements. However, it's important to ensure that the aluminum strips are properly installed and meet building codes for safety and effectiveness.</p>

- Q: Explain how aluminum strips play a role in enhancing energy efficiency.

- <p>Aluminum strips contribute to energy efficiency primarily through their use in thermal insulation and reflective properties. In building construction, aluminum strips can be used to create airtight seals around windows and doors, reducing heat transfer and drafts, which in turn lowers the need for heating or cooling systems. Additionally, aluminum's reflective nature can be utilized in radiant barriers, which reflect heat away from buildings, reducing the energy required for cooling. In electrical applications, aluminum strips are used in high-efficiency transformers and electrical conductors due to their high conductivity and light weight, reducing energy loss during transmission. Overall, aluminum strips enhance energy efficiency by minimizing heat loss and improving the performance of energy systems.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of using aluminum strips as a roofing material.

- <p>Aluminum strips for roofing offer several advantages, including durability, resistance to corrosion and rust, and low maintenance requirements. They are lightweight, which reduces the load on the structure, and can be easily recycled. Additionally, aluminum strips can be coated with various finishes to match architectural styles, enhancing aesthetic appeal. However, they also have some disadvantages, such as being more expensive than traditional materials like asphalt shingles. They can also be noisy during rain and hail, and may require professional installation due to their specialized nature.</p>

- Q: The question asks if it's possible to use aluminum strips as flooring material in kitchen or bathroom areas.

- <p>Aluminum strips can be used for flooring in kitchens and bathrooms, but they are not the most common choice. They are known for their durability, resistance to moisture, and ease of cleaning, which are desirable traits for these areas. However, they can be slippery when wet, making them a less safe option for bathrooms. They also lack the warmth and comfort of other flooring materials, like tiles or wood. For kitchens, aluminum strips can be a good option for their low maintenance and resistance to spills, but they may not provide the aesthetic appeal that many homeowners desire. It's important to consider the specific needs and preferences of your space when choosing flooring materials.</p>

Send your message to us

Aluminum Strips Bunnings 8011 Grade DC&CC Aluminum Coil, Plate, Aluminum Sheet Stocks for Aluminum Foil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords