Aluminum Diamond Plate Sheets for Sale - Aluminum Checkered Coil 1050 H14 with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

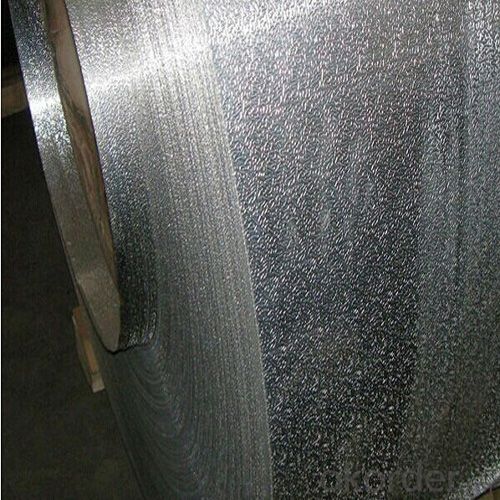

1.Structure of Aluminum Checkered Coil 1050 H14 Description:

The aluminum embossed sheets are used in many places, transportation, decoration, construction, Packing and so on.The main products of our company are aluminium sheet, coil, aluminium embossed sheet, aluminium foil and aluminium circle. Aluminium embossed sheets include stucco embossed aluminium sheet, five-bars embossed aluminium sheet, diamond embossed aluminium sheet, etc. They are widely used in daily life.

2.Main Features of Aluminum Checkered Coil 1050 H14:

Corrosion resistant

High forming property

Best Price

High Quality

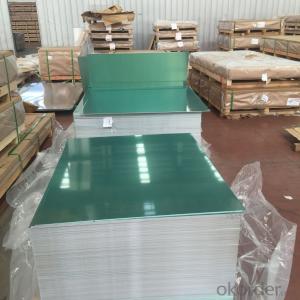

3.Aluminum Checkered Coil 1050 H14 Images:

4. Aluminum Checkered Coil 1050 H14 Specification:

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Ti | Al |

| 1060 | 0.2 | 0.25 | 0.05 | 0.03 | 0.03 | 0.05 | 0.015-0.02 | 99.6 |

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | 0.05 | 0.015-0.02 | 99.5 |

| 1100 | 0.2 | 0.5-0.6 | 0.05 | 0.05 | - | 0.05 | 0.015-0.02 | 99.0 |

| 1235 | 0.65 | 0.05 | 0.05 | 0.05 | 0.1 | 0.06 | 99.35 | |

| 3003 | 0.2 | 0.3-0.45 | 0.05-0.15 | 1.05-1.35 | - | 0.10 | - | - |

| 3102 | 0.2 | 0.1-0.4 | <0.1< span=""> | 0.1-0.4 | - | <0.05< span=""> | <0.05< span=""> | - |

| 3105 | 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.4 | 0.1 | - |

| 5052 | 0.088 | 0.296 | 0.007 | 0.038 | 2.253 | 0.009 | 0.012 | - |

| 8011 | 0.55-0.59 | 0.69-0.75 | 0.02 | 0.025 | 0.01 | 0.01 | 0.015-0.02 | - |

| 5083 | 0.4 | 0.4-1.0 | 4.0-4.9 | 0.25 | R | |||

| 5754 | 0.07 | 0.3 | 0.006 | 0.18 | - | - | 0.016 | R |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.25 | 0.15 | R |

| 6082 | 0.8-1.5 | 0.5 | 0.1 | 0.4-1.0 | 0.6-1.2 | 0.2 | 0.1 | R |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: What are the common applications of aluminum sheets in construction?

- Aluminum sheets have various applications in the construction industry due to their unique properties and versatility. Some of the common applications of aluminum sheets in construction include roofing, siding, and cladding. Aluminum sheets are lightweight yet durable, making them ideal for roofing applications as they can withstand harsh weather conditions, such as strong winds and heavy rainfall, without corroding or deteriorating. In siding applications, aluminum sheets are commonly used due to their ability to resist rust and corrosion. They provide an aesthetically pleasing finish to buildings, enhancing their overall appearance. Additionally, aluminum sheets can be easily shaped and bent to fit the desired design, making them suitable for curved or intricate architectural designs. Cladding is another common application of aluminum sheets in construction. Aluminum cladding is used to cover the exterior walls of buildings, providing insulation and protection against weather elements. It helps to reduce the energy consumption of buildings by acting as a thermal barrier, keeping the interior cool in summer and warm in winter. Aluminum cladding is also fire-resistant, making it a safe choice for construction projects. Moreover, aluminum sheets are frequently used in the construction of windows and doors. Their lightweight nature makes them easy to handle and install, while their strength ensures durability and longevity. Aluminum sheets can be powder-coated or anodized, allowing for a wide range of color options to suit different architectural styles and preferences. Overall, the common applications of aluminum sheets in construction encompass roofing, siding, cladding, windows, and doors. Aluminum's lightweight, durable, and corrosion-resistant properties make it an excellent choice for various construction projects, providing both functional and aesthetic benefits to buildings.

- Q: Can aluminum sheets be used for decorative panels?

- Aluminum sheets are indeed suitable for decorative panels. Being a lightweight and versatile material, aluminum can be easily shaped, cut, and molded into various designs and patterns. Its sleek and modern appearance makes it a popular option for decorative purposes in both residential and commercial settings. Aluminum panels have a wide range of applications, including wall cladding, ceiling panels, room dividers, signage, and more. Moreover, aluminum is resistant to corrosion and weathering, making it suitable for both indoor and outdoor use. Additionally, aluminum panels can be personalized with different finishes, such as powder coating or anodizing, to enhance their visual appeal. In conclusion, aluminum sheets are an excellent choice for creating decorative panels due to their pleasing aesthetics, durability, and adaptability.

- Q: Can aluminum sheets be laminated with other materials?

- Indeed, it is possible to laminate aluminum sheets with alternative substances. Lamination denotes the fusion of multiple layers of diverse materials, thereby yielding a composite material that possesses heightened qualities. Aluminum sheets can be laminated with a variety of materials, including plastics, fabrics, papers, or other metals, through the utilization of either adhesive bonding or the application of heat and pressure. This process of lamination facilitates the amalgamation of favorable attributes from distinct materials, ultimately yielding a final product that exhibits elevated strength, durability, appearance, or specific functionality. Laminated aluminum sheets find widespread employment in industries such as construction, automotive, aerospace, and packaging, where the amalgamated properties of the laminated substances confer distinct advantages.

- Q: Can the aluminum sheets be used for manufacturing electrical connectors?

- Yes, aluminum sheets can be used for manufacturing electrical connectors. Aluminum is a lightweight and highly conductive metal, making it suitable for transferring electricity. It is often used in various electrical applications, including connectors, due to its excellent conductivity and corrosion resistance. Additionally, aluminum can be easily shaped and formed into different connector designs, making it a versatile material for manufacturing electrical connectors.

- Q: Can aluminum sheets be used for food packaging?

- Yes, aluminum sheets can be used for food packaging. Aluminum is a popular material choice for food packaging due to its unique properties. It is lightweight, flexible, and has excellent barrier properties, which means it can effectively protect food products from moisture, light, oxygen, and other external contaminants. Aluminum sheets are commonly used for packaging various food items such as beverages, canned goods, ready-to-eat meals, and snacks. Additionally, aluminum is also recyclable, making it an environmentally friendly choice for food packaging.

- Q: Would a chemical reaction happen between a piece of copper and a liquid solution containing a compound of aluminum? Why or why not? FIRST BEST ANSWER GETS POINTS!

- Since Al is more reactive than Cu, no reaction would occur. A reaction would occur only if you had a piece of Al and a solution containing Cu2+ ions. The more active metal replaces the other metal in solution and the less active metal plates out.

- Q: How do aluminum sheets perform in terms of thermal expansion and contraction?

- Aluminum sheets have a relatively high coefficient of thermal expansion, meaning they expand more than other materials when heated and contract more when cooled.

- Q: does anyone know how aluminum recycling works in term of redox reaction ( oxidizing, reduced, oxidizing agent, reducing agent?). how is that relate to the process of electrochemistry?

- Aluminum recycling is done by just melting the cans back into molten metal. There are reactions, but those deal with the impurities, not the aluminum. See the reference.

- Q: Are aluminum sheets suitable for HVAC applications?

- Yes, aluminum sheets are suitable for HVAC (Heating, Ventilation, and Air Conditioning) applications. Aluminum is a popular material choice for HVAC systems due to its various beneficial properties. Firstly, aluminum is lightweight, which makes it easier to handle and install in HVAC systems. This is particularly important for large systems that require a significant amount of material. Secondly, aluminum is highly resistant to corrosion, making it ideal for use in HVAC applications where exposure to moisture and condensation is common. This resistance to corrosion ensures the longevity and durability of the HVAC system, reducing maintenance and replacement costs in the long run. Additionally, aluminum has excellent thermal conductivity, allowing it to efficiently transfer heat or cold air throughout the HVAC system. This property helps to ensure efficient heating and cooling, reducing energy consumption and resulting in cost savings for the user. Furthermore, aluminum sheets can be easily formed and shaped to fit specific HVAC requirements, allowing for customized designs and precise installation. This versatility makes aluminum a preferred choice for ductwork, heat exchangers, and other components in HVAC systems. Overall, aluminum sheets are well-suited for HVAC applications due to their lightweight, corrosion resistance, thermal conductivity, and flexibility. These properties contribute to the efficiency, durability, and performance of HVAC systems, making aluminum a preferred material in the industry.

- Q: There are about 200 holes on the aluminum plate to be machined. There are 100 M12 thread holes, and the rest are 15MM through holes. The tolerance is +0.02. Seeking detailed processing technology, is the first hole or first processing plane, how to control the amount of deformation of the plate, if the milling process can not guarantee flatness, on the grinder, then the 2 surfaces to stay 2MM margin? Are there any 15MM through holes that can be used to maintain tolerances, or do they need to be boring?. Great God advice, the best detail. Aluminum so much done before, no experience, if it does it scrapped.

- The thickness of 2 to 1. fly in place stress to ensure the flatness of the fitter leveling 0.13 more than the Xicheng pay attention to the protection of the appearance of 4 to ensure the flatness of the fabricated fitter. - this thing must not need to be so high, 100 M12 threaded holes, you still press the map to ensure that ah? Such a large plate deformation, 2 millimeters below the hole can be pressed to do

Send your message to us

Aluminum Diamond Plate Sheets for Sale - Aluminum Checkered Coil 1050 H14 with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords