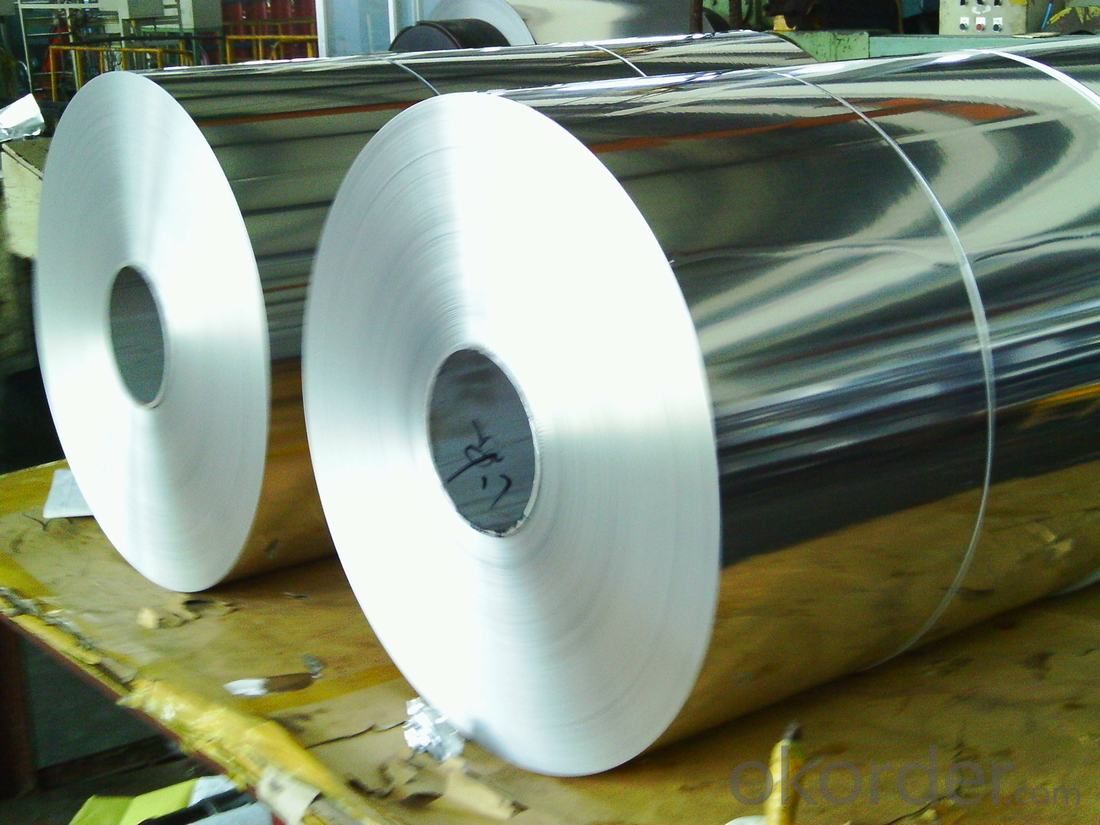

Marine Grade Aluminum Sheets - CC Grade 1100/1050/1020/1060 Aluminum Coils with Bright Surface

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum Description

-Hot rolling 1100/1050/1020/1060 aluminum coils for roof sheet is used for celling, decorate, ACP,Curtain Wall,Roofing Sheet, PC base, radiator,cookware,deep drawing and more.

- 1 series Aluminum Coils temper: O-H112

-1 Series Aluminum Coils Alloy: 1100/1050/1060/1200/1035/1070

-Thickness: 0.5-10mm

-Width:200-1500mm

-Length:12m Max.

Temper: h14,h16,h18,h22,h24,h26,h32,o/f

Thickness: o.o3mm-3.0mm

Width: 30mm-1700mm

Coating: pe(polyester),pvdf,epoxy

Painting thickness: standard 16-25 mic, max 40 mic

Color: according to ral colors or customer's samples

Packaging & Delivery

| Packaging Details: | Coil ID :508MM Coil Weight : about 2.5 tons or as per customers requirement Packing ; In Export Sea worhty wooden pallets Eye to wall or Eye to Sky One container can be loaded about 20 mts |

| Delivery Detail: | within 25 days after receiving L/C deposit |

- Q: How to distinguish fluorocarbon spraying and powder spraying aluminium plate

- 3, powder coating is spraying equipment (electrostatic spray machine) the powder coating is sprayed onto the surface of the workpiece under the electrostatic interaction, the powder will be uniformly adsorbed on the surface of the workpiece, the formation of powder coating; powder coatings after high temperature baking leveling curing, into effect (different effect of different kinds of powder coatings in the final) powder coating; spraying effect on mechanical strength, adhesion, corrosion resistance, aging resistance and superior cost in spray painting process, under the same effect.

- Q: Are 101 aluminum sheets suitable for chemical transfer piping?

- Chemical transfer piping cannot rely on 101 aluminum sheets as they are unsuitable. The reactivity and corrosion propensity of aluminum make it generally unfit for handling specific chemicals. Industries like aerospace or construction prefer aluminum due to its lightweight nature and excellent thermal conductivity. However, for chemical transfer piping, it is wiser to opt for materials that possess corrosion resistance and can endure the specific chemicals being transported. Stainless steel, PVC, or high-density polyethylene (HDPE) are recommended alternatives.

- Q: I am doing a project on Aluminum it has 13 protons just to make sure everyones on the same page. How much of it is left or exsits? Also how does it behave?

- Aluminium is one of the most abundant Element on earth, ranking 3rd in the crust, second only to oxygen and silicon. And it is eminently recyclable. However, many minerals containing aluminium are not economically exploitable.

- Q: what's the size of gap while pressing 6mm aluminum sheet?

- choose the 8-10% of the thickness for two-sided gaps.

- Q: Is aluminum suitable for projects with heavy traffic or frequent use?

- <p>Yes, aluminum sheets can be used in projects that involve high levels of traffic or heavy use. Aluminum is a lightweight, durable, and corrosion-resistant material. It can withstand significant wear and tear, making it suitable for high-traffic areas. Additionally, aluminum is easy to maintain and can be recycled, which is beneficial for long-term projects. However, it's important to consider the specific grade of aluminum and its thickness to ensure it meets the required strength and durability for your project.</p>

- Q: This question asks for a list of the various types of profiles that can be made from aluminum sheets.

- <p>Aluminum sheet profiles come in a variety of types, suitable for different applications. Some common types include: 1. Flat Sheets: These are simple, flat aluminum sheets with no bends or curves. 2. Corrugated Sheets: These have a wavy or ridged pattern, providing strength while allowing flexibility. 3. Perforated Sheets: These have holes punched in a regular pattern, useful for ventilation or decorative purposes. 4. Embossed Sheets: These have a raised pattern on the surface, often used for aesthetic or functional reasons. 5. Extruded Profiles: These are complex shapes created by pushing aluminum through a die, suitable for structural applications. 6. Expanded Metal Sheets: These have a diamond-shaped pattern, providing strength and rigidity. 7. Checkered Plates: These have a raised, non-slip pattern, often used for flooring. Each type has its own specific uses and properties, and the choice depends on the requirements of the project.</p>

- Q: Is it possible to use adhesive instead of fasteners to bond aluminum sheets to a structure?

- <p>Yes, you can use an adhesive to attach aluminum sheets to a structure. However, it's important to choose an adhesive that is specifically designed for bonding aluminum, as not all adhesives provide the necessary strength and durability. Structural adhesives that are compatible with aluminum can offer a strong bond and are often used in applications where a clean, seamless appearance is desired or where fasteners are not suitable. It's crucial to ensure that the adhesive is resistant to the environmental conditions the structure will be exposed to, such as moisture, temperature fluctuations, and UV radiation. Always follow the manufacturer's instructions for surface preparation and application to achieve the best results.</p>

- Q: What are the different methods of surface laminating aluminum sheets?

- There exist various techniques for surface laminating aluminum sheets, each with its own distinct advantages and suitability for different purposes. Some of the commonly utilized methods comprise: 1. Adhesive bonding: This involves the application of an adhesive layer between the aluminum sheet and the desired surface material. The adhesive is typically cured through the application of heat or pressure, resulting in a robust bond. This technique is versatile and can be employed with a range of surface materials, including wood, plastic, or glass. 2. Roll bonding: Also referred to as cladding or cold roll bonding, this method entails placing the aluminum sheet between two other metal sheets and subjecting them to high pressure to create a solid bond. Roll bonding is frequently employed in the production of composite materials, such as aluminum-clad steel sheets. 3. Thermal spraying: This process entails melting or heating aluminum powder and using a thermal spray gun to spray it onto the sheet surface. The molten aluminum solidifies upon contact, forming a durable coating. Thermal spraying is commonly used for corrosion protection or as a foundation layer for subsequent surface treatments. 4. Powder coating: In this technique, a dry powder paint is electrostatically applied to the surface of the aluminum sheet. The sheet is then heated, causing the powder to melt and form a smooth and protective coating. Powder coating offers exceptional durability, impact resistance, and a wide array of color options. 5. Anodizing: Anodization is an electrochemical process that enhances the natural oxide layer on the surface of aluminum sheets. By immersing the sheet in an electrolytic bath and applying an electric current, a controlled oxide layer is formed, providing corrosion resistance, improved adhesion for paint or adhesive, and aesthetic finishes. 6. Lamination with protective films: A plastic protective film can be applied to the surface of the aluminum sheet for safeguarding purposes during transportation, handling, or processing. These films offer temporary protection against scratches, abrasions, and dirt. These represent just a few among many techniques available for surface laminating aluminum sheets. The choice of method depends on factors such as desired properties, intended use, and specific application requirements.

- Q: What does aluminum plate "1060-H24" mean?

- Four, H24 H said the work hardening of the state, and some do not have H but T said it is heat treatment.24 machining process control hardness and other properties, in addition to 24 and 12, 14, 16, 18, 22, 26, 34, 36 and so on, usually at the end of 4 is a semi hard state.1060O, 1060-H22, 1060-H24, 1060-H18 state is arranged from soft to hard.

- Q: This question asks for a comparison of the positive and negative aspects of utilizing aluminum sheets in building construction.

- <p>Aluminum sheets in construction offer several advantages, including lightweight properties that reduce structural load, excellent corrosion resistance, and durability which minimizes maintenance needs. They are also energy-efficient, reflecting heat and reducing cooling costs. Additionally, aluminum is recyclable, contributing to sustainability. Disadvantages include higher initial costs compared to some traditional materials and potential for dents or damage from impacts. Aluminum can also be noisy when walked on, and it may require additional insulation for thermal performance, adding to the overall cost.</p>

Send your message to us

Marine Grade Aluminum Sheets - CC Grade 1100/1050/1020/1060 Aluminum Coils with Bright Surface

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords