8 Micron Silver Metallized PET Film MPET for Food & Medicine Package

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

8 Micron Silver Metallized PET Film MPET for Food & Medicine Package

Dear customers,

We are the only nationalized business manufacturer of packaging film, was founded in 1995.

Our company is specializing in metallized cpp pet (vmcpp & vmpet) for more than 22 years. We are proud of first quality with outstanding service and competitive price. Hope to cooperate with you in the future.

| Setting Information | |

| Name | Metalized VMPET film |

| Material | VMPET film for lamination |

| Property | Indicators |

| Application | Package |

| Processing Type | Casting |

| Usage | Packaging Film |

| Inner core | 95MM |

| Thickness | 12mic-180mic |

Product Description

VMPET film for lamination

Good ventilation, antistatic and transparency

Non-toxic and eco-friendly, biodegradable and recycled

Good print ability, distinguished gloss, excellent abrasion resistance

Custom size and design ,different sizes for various choices

Widely used for food and gifts packing, bags and so on

High tensile strength, low static

Excellent stiffness and fold ability

Good heat sealing ability in high speed

| Model | vmpet12 | vmpet60 | vmpet180 |

| Thickness | 12mic | 160mic | 180mic |

| Optical density | 1.6-2.4 | 1.6-2.4 | 1.6-2.4 |

| Inner core | 3" or 6" | 3" or 6" | 3" or 6" |

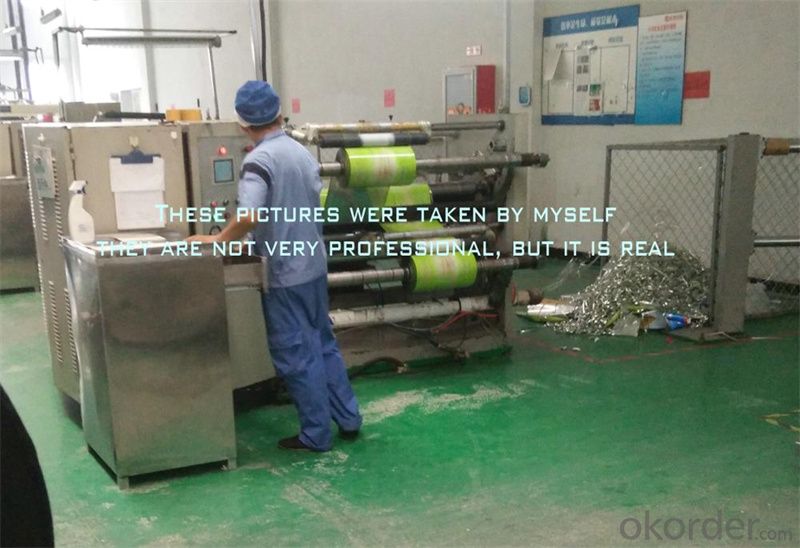

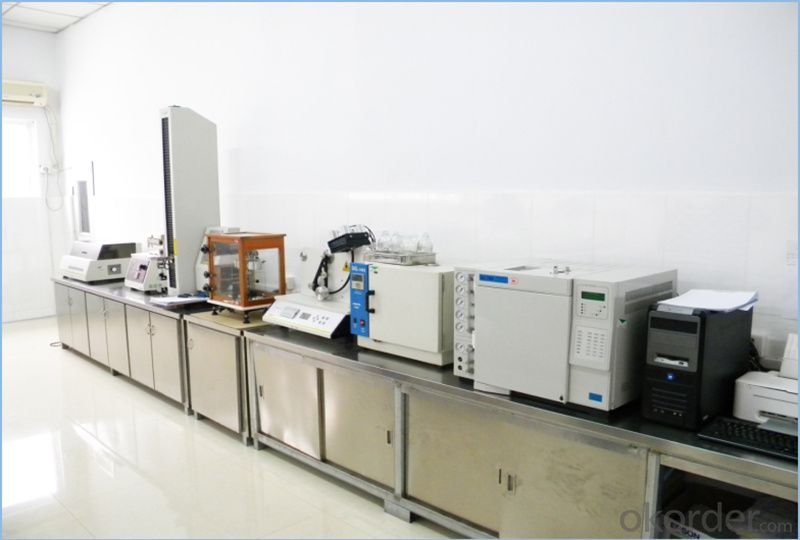

Device Show

- Q: What is the effect of plastic film on waterproof coiled material?

- As a waterproof reinforcing layer (the plastic film itself is waterproof, but the strength is poor, and the asphalt layer plays a complementary role)

- Q: Plastic film has eyes, how to make up?

- Using organic solvent cyclohexanone (six carbon ketone) to repair, but the best buy for repair, repair film glue (such as PVC entrail agent). The method is to first clean interface, with brush glue, dry 2-3 minutes, the film patch affixed, 2 hours after the cement can be used.

- Q: What are the factors affecting the permeability of plastic film?

- Water column height. In the water permeability test, the water quantity in the water cup is changed, indicating that the water column height has no influence on the test result, so the water quantity is not strictly controlled, and the amount of the water can be poured into the water permeable cup with proper amount of water.

- Q: In a bowl with the seeds covered with plastic film, you need time off the air

- Plastic film cover in order to keep the soil moisture in the soil, air breathing for seed germination and growth of enough, only to grow seedlings, to remove the cover film, otherwise the film may have a high temperature.

- Q: Are floor mats made of ordinary plastic sheeting?

- But in the damp ground or geothermal conditions in tidal and geothermal temperature (especially geothermal temperature exceed the standard) under the action of the tape is extremely easy to cause the joint degumming, breathable, causing the floor bulge, Alice, sound or color etc.

- Q: Is it possible to lay a plastic film between the roof slab and concrete for waterproofing purposes?

- The seam of the prefabricated plate is very easy to crack. The plastic film is not good enough and is easy to pierce. Once it rains, it basically can't get waterproof effect;

- Q: How often will the plastic film in the greenhouse be replaced?

- There is no fixed deadline, mainly to see the integrity and transparency of the greenhouse films, if maintain proper, by cleaning and repairing can meet the use requirements, can be reused for years, saving the cost; if improper maintenance, natural or man-made damage is serious, a year could be replaced several times.

- Q: Iron gate plastic film for a long time, how to remove?

- Heating with electric wind can tear it off.Fengyoujing.To sell motorcycle accessories shop, buy a carburetor cleaning agent, a spray, and so on 1 minutes and then brush, just OK!

- Q: How to make a round hole in plastic film

- If it is a film with perforated, hollow metal objects will need to choose according to the size of the round hole relatively hard round, such as diameter of the pipe. Similarly, after heating quickly and vigorously press (weight hit), in need of drilling position, with more drilling, the need for speed is very fast, the instantaneous strength can be great, otherwise the film will scorch damaged.

- Q: How can concrete pavement be cured after being pressed? In general, concrete curing is made of thin films and concrete pavements

- When the concrete surface has a hardness, generally gently press no trace, also can be used wet mats or wet sacks covering, sprinkler maintenance should pay attention to water can not be poured directly on the concrete surface, when encountered heavy rain or high winds, wet grass covered in time to pad. Every day with special hand sprinkler maintenance, keep the grass pad or gunny bag moist. The concrete strength of adding water reducing agent can reach 80% or more in 5 days. At this time, the straw mat, plastic film or wet gunny bag can be removed. After the release, the water needs to be maintained for 2~3 days.

Send your message to us

8 Micron Silver Metallized PET Film MPET for Food & Medicine Package

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords