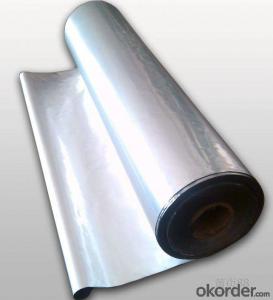

Aluminium Coated Metallized Polyester PET MPET Film for Packaging

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminium Coated Metallized Polyester PET MPET Film for Packaging

Dear customers,

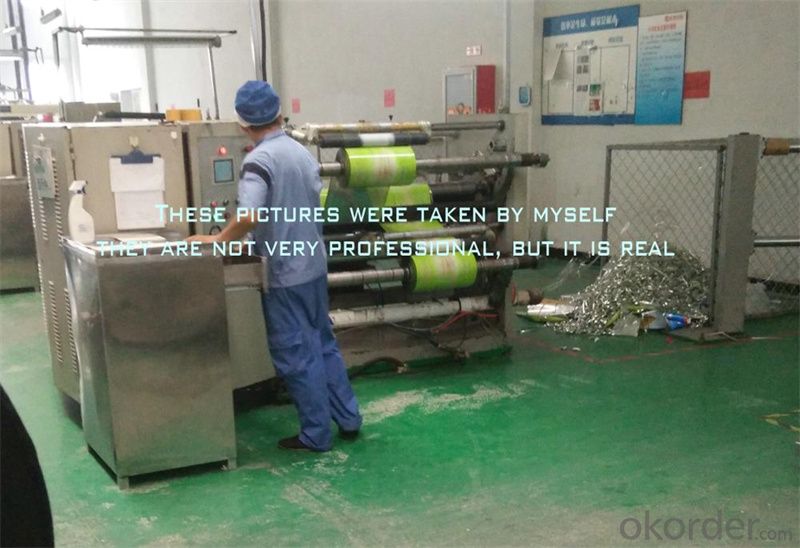

We are the only nationalized business manufacturer of packaging film, was founded in 1995.

Our company is specializing in metallized cpp pet (vmcpp & vmpet) for more than 22 years. We are proud of first quality with outstanding service and competitive price. Hope to cooperate with you in the future.

| Setting Information | |

| Name | Metalized VMPET film |

| Material | VMPET film for lamination-LN2 |

| Property | Indicators |

| Application | Package |

| Processing Type | Casting |

| Usage | Packaging Film |

| Inner core | 95MM |

| Thickness | 12mic-180mic |

Product Description

VMPET film for lamination

Good ventilation, antistatic and transparency

Non-toxic and eco-friendly, biodegradable and recycled

Good print ability, distinguished gloss, excellent abrasion resistance

Custom size and design ,different sizes for various choices

Widely used for food and gifts packing, bags and so on

High tensile strength, low static

Excellent stiffness and fold ability

Good heat sealing ability in high speed

| Model | vmpet12 | vmpet60 | vmpet180 |

| Thickness | 12mic | 160mic | 180mic |

| Optical density | 1.6-2.4 | 1.6-2.4 | 1.6-2.4 |

| Inner core | 3" or 6" | 3" or 6" | 3" or 6" |

- Q: Wood composite doors, plastic film paste on how to deal with?

- Preparation tools: hair dryer (with hot air), 1 steel wire ball (slightly thinner wire), 1 bottles of white wine, 2 pieces of dishcloth

- Q: What is concrete plastic sheeting for moisture conservation?

- Plastic cloth maintenance: plastic sheeting is used to cover the concrete surface, curing the concrete.

- Q: The material, characteristics and uses of various plastic films

- This product of EVA film blowing out the most used plastic film, greenhouse film, bags and other uses in bacteria.These products are the most common and most commonly used in our life. Both the production and sales volume are very large, and they are in use both at home and abroad.Hope to help you; if you don't understand, you can continue to ask.

- Q: What kind of material is plastic film in greenhouse?

- Plastic film material in greenhouse:Common filmPolyethylene or polyvinyl chloride as raw material, the film thickness of 0.1 mm, colorless transparent. The service life is about half a year.

- Q: What material is the film on the waterproof roll? What's your name?

- The construction of other structural layers on the waterproof layer may puncture the damaged waterproof layer, and proper protection is necessary, and the isolating layer can also play a protective role at the same time.

- Q: Building floor pouring why plastic film underneath?

- Only after the completion of casting, the surface of the filmThe reason is to prevent surface cracking;The question of the subjectPrevent moisture from the floor, affect the quality of the pouring

- Q: Installation of air-conditioning machine inside the plastic film did not take off, the impact on the air-conditioning?

- The external machine is higher than the internal machine, if it is a new machine, the contradiction shows little, once the time is long, there will be a problem.The biggest problem is the oil return system, compressor in high evaporator in the lower, especially in the refrigeration temperature, oil viscosity, oil is not easy to return to the compressor, the compressor oil shortage, especially in the course of time, easy to damage.

- Q: What are the plastic film types and scope of use?

- LDPE films are usually made of two kinds of blow molding and tape casting. Cast PE films are of uniform thickness, but are widely used because of their high cost and low cost. LDPE film is a semi transparent, glossy and soft film with excellent chemical stability, heat sealing property, water resistance and moisture resistance. It can be frozen and boiled. The main drawback is that the oxygen barrier property is poor, the inner membrane is commonly used in soft packing materials, and is currently the most widely used, one of the largest amount of plastic packaging film, accounting for more than 40% of the consumption of plastic packaging film.Due to the polar group containing polyethylene molecules, and high crystallinity, low surface free energy, therefore, the poor performance of the film printing, ink and adhesive adhesion is poor, so the surface treatment in printing and composite before.

- Q: What are the differences between geotextiles and geomembrane?

- Geotextiles, also known as geotextiles, are synthetic geosynthetics made from synthetic fibers by means of needle or weave. The finished product is in a cloth shape with a width of 4-6 meters and a length of 50-100 meters. Geotextiles are divided into woven geotextile and nonwoven geotextile. Geotextile has excellent filtration, drainage, isolation, reinforcement, seepage prevention and protection. It has light weight, high tensile strength, good permeability, high temperature resistance, cold resistance, aging resistance and corrosion resistance.

- Q: How can concrete pavement be cured after being pressed? In general, concrete curing is made of thin films and concrete pavements

- The best way is: the final condensate to the wet cover after maintenance.Can buy a cheap regeneration blanket, inside is recycled knitting silk, the outside is recycled cotton, commonly known as "black heart cotton" material. A lot of furniture transportation is also used to put the bump.

Send your message to us

Aluminium Coated Metallized Polyester PET MPET Film for Packaging

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords