Silver Coated Metalized PET Film With Good Quality

- Loading Port:

- Ningbo Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1*20'FCL m.t.

- Supply Capability:

- 700 Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction Of Silver Coated Metalized PET Film With Good Quality:

Metalized PET film is an improved surfacing material for SBS/APP modified bitumen waterproofing membrane. It has all the aluminum foil functions. Since it is the lamination of PET/PE film and aluminum foil, it is more flexible and with higher strength.

Technical Data Of Silver Coated Metalized PET Film With Good Quality:

PROPERTIES | TYPICAL DATA |

COMBINED THICKNESS | 35--40 MICRON |

| PET FILM:12MICRON ALUMINUM FOIL:10MICRON PET FILM:12 MICRON |

UNITE WEIGHT | 60-70 G/M2 |

WIDTH | 1020 MM |

SURFACE FINISH | TOP: PET FILM MIDDEL: ALUMINUM FOIL BOTTOM: PET FILM |

TENSILE STRENGTH | LONGITUDINAL> 40 N/15MM TRANSVERSAL> 50 N/15MM |

ELONGATION AT BREAK | LONGITUDINAL>10 TRANSVERSAL>15 |

I.D. | 75-80MM |

O.D.OF ROLL | 450-550MM |

SD VALUE | 7000M(APPROX) |

WATER VAPOUR PERMEABILITY | <0.02 G/M2 D |

COMPOUND CHARACTERISTICS | THE COMPOUND DOES NOT CHANGE ITS CHARACERISTICS WHEN USED AT 180 ℃ IN A SHORT BITUMEN CYCLE |

Remark :

The above technical data form is for our normal specification. Other specifications are available based on customer’s requirements.

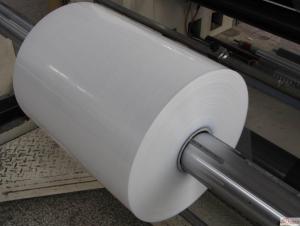

Package Of Silver Coated Metalized PET Film With Good Quality:

Each roll is wrapped with plastic film, and then put into wooden boxes, 80 rolls are put into 1*20FCL. Based on quantity, special package is available.

Pictures Of Silver Coated Metalized PET Film With Good Quality:

- Q: What is the impact of TPO waterproofing membrane welding performance?

- Dow Chemical TPO and Basel TPO due to the different grades of production technology, raw material ratio is different from the formula system for the performance of the material melting point, polymerization, molecular weight distribution index, melt index, melt strength, weldability are not same. It is recommended that attention be given to the above factors in the course of the test

- Q: Waterproof electrode, waterproof welding

- Sewage equipment repair with time urgency, uncertainty, characteristics of labor intensity and so on. Requiring repair personnel in the shortest possible time to complete the repair and safe and efficient tasks, to ensure smooth flow. But in the process of repair the situation is changing, and sometimes seemingly simple process often have unexpected circumstances. Such as steel pipe repair, in general, as long as the welding can be, but sometimes for some reason the water inside the pipeline can not drain, which to welding and cutting to bring great difficulties

- Q: Surfacing isolation layer is the application of what, how to achieve surfacing isolation layer weld.

- Surfacing as a material surface modification of an economical and rapid process, more and more widely used in various industrial sector parts manufacturing repair.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2004 |

| Annual Output Value | Above RMB100 Million |

| Main Markets | China; Eastern Europe; East Asia; Japan; Western Europe; Africa; Southeast Asia; North America; South America; Hong Kong and Taiwan. |

| Company Certifications | ISO9000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Ningbo port; Shanghai port. |

| Export Percentage | >50% |

| No.of Employees in Trade Department | 8-10 people |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 30,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Silver Coated Metalized PET Film With Good Quality

- Loading Port:

- Ningbo Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1*20'FCL m.t.

- Supply Capability:

- 700 Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches