Mylar Lamination Film- 60mm Width Aluminum Foil/Polyethylene

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Structure

Widely used for laminating with EPE insulation, Bubble insulation, woven fabric insulation, etc

● Aluminum foil – LDPE

● Aluminum foil- PET- LDPE

● Clear Transparent PET-Aluminum foil – LDPE

● Aluminum foil-Metallized PET- LDPE

● Metallized PET- LDPE

Product Application

Widely used for laminating with EPE insulation, Bubble insulation, woven fabric insulation, etc

Product Advantage

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• Environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Product Packing

1. Waterproof paper then PVC shrinking Film

2. Kraft paper only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

Product Remarks

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

Product Data Sheet

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 33.5 | ASTM D646 |

Thickness | mic | 23.2 | ASTM D646 |

Tensile strength: M. D. X. D. | N/15mm | 13.5 13.5 | ASTM D882 |

Delaminating Values | N/15mm | 1.5 | ASTM D904 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -40°C 130°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permanence | ng/N.s | 1.15 | ASTM E-96 |

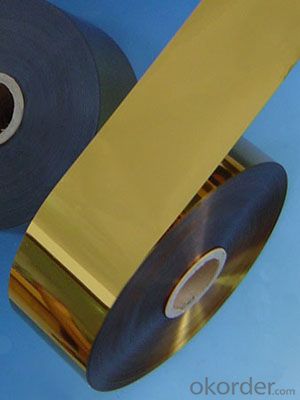

Product Picture

FAQ

1. What is the product keeping conditions?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

2. What is the guarantee years of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. What is the delivery time of the order?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Excuse me, where can I buy a special transparent plastic film?

- In fact, in potting materials covered with a layer of plastic film, some of the treatment can be isolated ultraviolet light, part of the treatment of light intensity is different.

- Q: Such equipment is used for cutting paper?

- Then put the plastic film along the width direction of fiber board wrapped up, usually wrapped around twenty to fifty layers, the thickness of plastic film and video.

- Q: Several forming methods of plastic film and their advantages and disadvantages are summarized

- Plastic film forming usually blow molding, tape casting, rolling method.Blow molding is generally used to make PE films, PVC filmsThe tape casting method mainly produces BOPP film, PET film and BOPA filmCalendering to produce PVC calendering films

- Q: What is the best plastic welding method?

- It must be welding with ultrasonic wave! Because he doesn't need other additives, and the efficiency and welding effects are not artificial. Unless you're a big plastic product.

- Q: Is it possible to lay a plastic film between the roof slab and concrete for waterproofing purposes?

- The roof is waterproof, or it is recommended to use professional waterproof material to do, in the prefabricated board paving finished, first with ordinary cement mortar leveling the ground, and then start waterproof.Roof waterproof, it is recommended to use rigid waterproof + flexible combination of waterproof construction. Thus, the utility model not only has the advantages of firm adhesion of the base surface, strong puncture resistance, high strength, but also can resist the stretching deformation of a certain extent of the base surface, and can meet the waterproof requirement of the roof for long time to be exposed to sunlight, rain and erosion.The specific construction method is to brush K11 waterproof slurry, flexible type, and then do a mortar waterproof agent protection layer, so that it can achieve good waterproof effect!Special reminder, the standard construction is a guarantee of good results, so must be in accordance with the requirements of standard construction, brushing thickness, height, interval time, etc., need attention.

- Q: What is the melting point of PET plastic film?

- PET has a high molecular structure and a certain crystalline orientation, so it has high film forming ability and plasticity. PET plastic has good optical properties and weather resistance, and amorphous PET plastic has good optical transparency. In addition, PET plastic has excellent wear resistance, friction and dimensional stability and electrical insulation. PET bottles are widely used because of their high strength, good transparency, non-toxic, impermeable, light quality and high production efficiency. PBT and PET molecular chain structure similar, most of the same nature, but the main chain from two methylene into four, so the molecules are more supple, processing performance is better.

- Q: How to identify the model of plastic greenhouse film?

- Thickness of what can be compared with your current use. General color slants blue, thickness is high, the price is expensive. Poor transparency, white, thin, low prices

- Q: When will the plastic film be opened when the vegetables are sprouting?

- One is to take mulch after sowing; two is the plant after the emergence of the seedlings at the top of the window film, let out seedling growth;

- Q: Wrap your legs in plastic film. How soon will they be removed?

- PVC film is mainly used in1. Sewage pipes2, PVC plastic film rod plate.3, construction, packaging, printing, equipment, process products.

- Q: How can the plastic film remove the static electricity?

- The problems you mentioned are very common. The static electricity on the plastic film is very large, or it is easier to get static electricity. It causes the dust to adsorb during the process of processing and finally causes bad

Send your message to us

Mylar Lamination Film- 60mm Width Aluminum Foil/Polyethylene

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords