Economic Metallized Film Packaging Material for Food and Medicine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Economic Metallized Film Packaging Material for Food and Medicine

Dear customers,

We are the only nationalized business manufacturer of packaging film, was founded in 1995.

Our company is specializing in metallized cpp pet (vmcpp & vmpet) for more than 22 years. We are proud of first quality with outstanding service and competitive price. Hope to cooperate with you in the future.

Does not contain hazardous chemicals o harmful materials that cause itching or respiratory problems.

Does not contain hazardous chemicals o harmful materials that cause itching or respiratory problems.

Reflects 97% radiant heat, improves insulation system performance, energy saving.

High tensile strength VMPET.

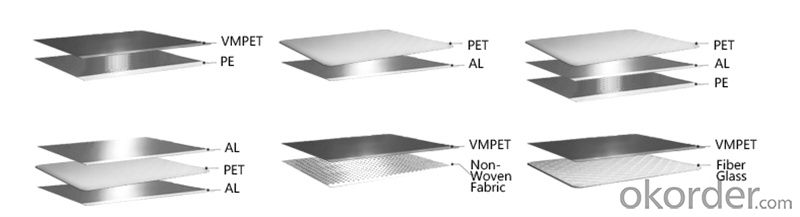

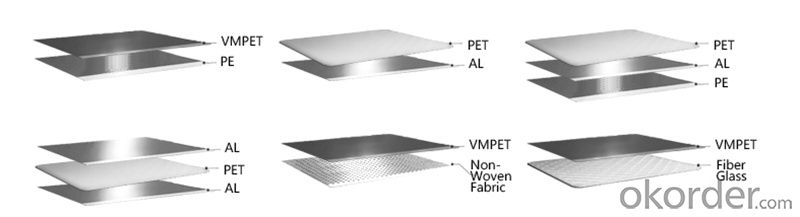

Economic metallized film mylar reflective material from factory

Easily install it on long-span building such as warehouse, factory building, supper market, gym, container liner VMPET.

| Setting Information | |

| Name | Metalized VMPET film |

| Material | VMPET film for lamination-LN2 |

| Property | Indicators |

| Application | Package |

| Processing Type | Casting |

| Usage | Packaging Film |

| Inner core | 95MM |

| Thickness | 12mic-180mic |

Product Description

VMPET film for lamination

Good ventilation, antistatic and transparency

Non-toxic and eco-friendly, biodegradable and recycled

Good print ability, distinguished gloss, excellent abrasion resistance

Custom size and design ,different sizes for various choices

Widely used for food and gifts packing, bags and so on

High tensile strength, low static

Excellent stiffness and fold ability

Good heat sealing ability in high speed

| Model | vmpet12 | vmpet60 | vmpet180 |

| Thickness | 12mic | 160mic | 180mic |

| Optical density | 1.6-2.4 | 1.6-2.4 | 1.6-2.4 |

| Inner core | 3" or 6" | 3" or 6" | 3" or 6" |

Our Advantage

Superiority of price: we control the whole process from raw materails purchasing to final product manufacturing.

Efficiency advantage: the fastest time of delivery is 7days.

Customization: all indicators could be customized which includes the thickness, width, length, diameter.

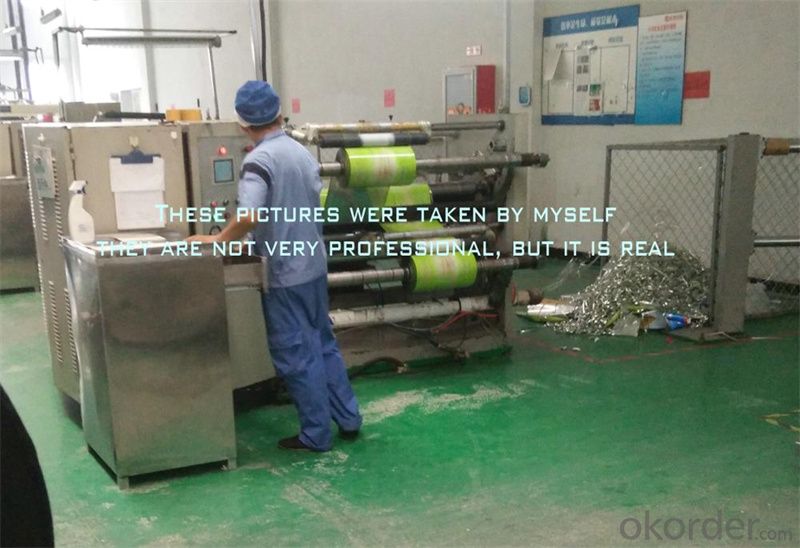

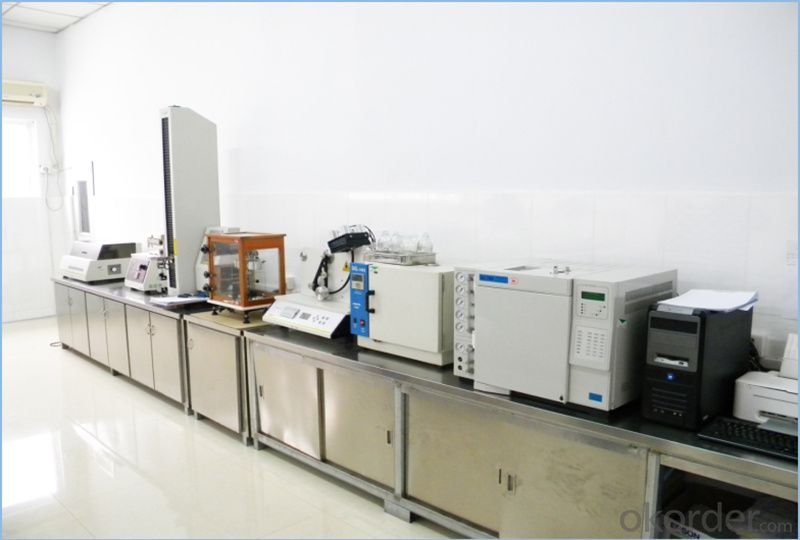

Device Show

- Q: Glued to the door, how can the plastic film be cleaned due to oxidation?

- With sulfuric acid water, diluted after immersion, the concentration can not be too high, otherwise it will corrode the door body, bubble finished with clean cloth can be wiped.

- Q: How much plastic film can melt?

- Polypropylene, referred to as PP, is a thermoplastic resin made from the polymerization of propylene. The melting point can be as high as 167 DEG C because of the highly crystalline structure.

- Q: Do I need to tear the plastic film of the barrel washing machine?

- If the paste is suitable, and does not affect the appearance, it is recommended to retain.This is actually similar to the mobile phone foil, how much of the surface a little protection, originally in order to produce the process of placing scratches.

- Q: What solvent can dissolve the plastic film on the glazed tiles without damaging the glazed tile surface?

- Vitreous tile is in fact full tile, the front and back color is basically the same, there is no obvious color difference, more wear-resistant, hardness, not brittle, with good machinability.

- Q: Is it possible to lay a plastic film between the roof slab and concrete for waterproofing purposes?

- Sure。 In the construction, the film can not be worn out, the effect is good, and the waterproof life is very long. I've done this before, and the film was good until the concrete was removed from the house. "It's been used for ten years.".

- Q: Is it beneficial or harmful to wrap trees in plastic film?

- The rope tied the rope tied thick film with the trunk, and the rope tied outside the water, moisturizing plastic film. The method of ground film mulching and pressing soil with the same method has obvious effect of moisture control and temperature adjustment, and is also beneficial for survival.

- Q: How to choose PE plastic packing film

- As a packaging material, plastic film is the most important and basic function for the protection of goods. If the plastic film has no reliable protection against the packaged goods and causes damage or depreciation of the goods, it will lose its value as a packaging material. The protective function of plastic film for goods is various. Different commodities and different packaging forms have different emphases on the protection function of plastic packaging film.

- Q: Will a plastic film attached to a computer screen help reduce computer radiation?

- Good skin care online prior to isolation, such as the use of pearl film, the unique "Pearl Tsui film" in the skin to form a layer of 0.001mm pearl film can effectively prevent the pollution of the environment and radiation damage; followed by computer use, the face will be a lot of electromagnetic radiation absorption of particles, must be promptly wash with water, that will make the radiation is reduced by more than 70%!

- Q: What kind of plastic film is a little sticky and can be affixed to the label perfectly? What is it like a sticker?

- PE electrostatic membrane is without glue, by electrostatic adsorption, can satisfy you with a little sticky this requirement.

- Q: What solvent can be used to remove the plastic film glued to the glass?

- The range of application is suitable for diluting all kinds of nitro wood paint.Product features:1, low odor, no residue2, strong solubility, good matching3, moderate drying speed, easy construction, preferably esters, alcohols, aromatic hydrocarbons and other organic solvents, low odor, good solubility, good construction performance, applicable to dilute all kinds of nitro wood paint.

Send your message to us

Economic Metallized Film Packaging Material for Food and Medicine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords