Aluminum Trailer Sheets - 7075 T6 T651 Aluminum Sheet for Moulding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

7075 T6 T651 Aluminum Sheet for Moulding

l Production Introduction

Chemical data:

| Silicon (Si) | Iron | Copper (Cu) | Manganese (Mn) | Magnesium (Mg) | Chromium (Cr) | Zinc | Titanium |

| (Fe) | (Zn) | (Ti) | |||||

| 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.20 |

| Aluminum Type / Temper | Minimum Tensile Strength (ksi) | Minimum Yield Strength (0.2%, ksi) |

| 7075 Aluminum Alloy | ||

| -T6 | 83 | 73 |

| -T651 | 83 | 73 |

| 7075 Aluminum Sheet and Plate | ||

| -T6 | 74-78 | 63-69 |

| -T651 | 67-78 | 54-68 |

| 7075 Aluminum Extrusionsc | ||

| -T6 | 78-81 | 68-73 |

| -T6510 | 78-81 | 68-73 |

| -T6511 | 78-81 | 68-73 |

l Packaging & Delivery

Packaging detail: Inner packing: each sheet is covered with PE film or kraft paper;

Outer packing: wooden pallet/case with seaworthy packing or as per customer's requirement.

Delivery detail: 20-25 days

l Company Profile

CNBM, China National Building Material Group Corporation is the largest state owned company under central government of China that deals with building materials and industrial equipment.

Since 1984, we are professional manufacturer of construction machinery and equipment with the brand CMAX. Here I recommend our Aluminium Treadplate to you.

We have our own factory, logistics system, e-business platform, and oversea warehouse. Our products meet international quality standard, with CE certificate.

l CNBM World Wide

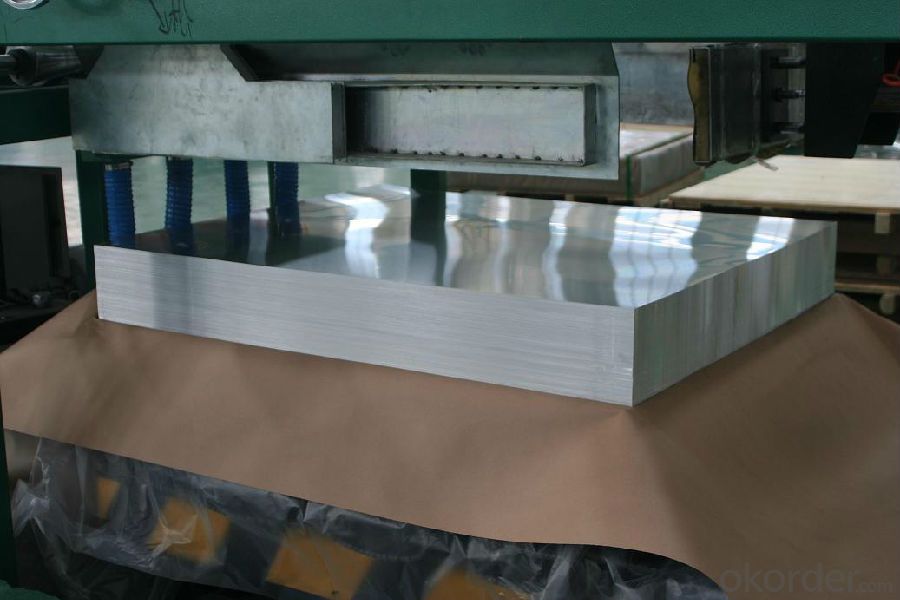

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons per size

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: AND WAT R THE THECNOLOGICAL ANDCOSTS AND BENEFITESOF USING ALUMINUM? what health -related and environment-related issues gave surface as aresult of its widespread use in society?

- airplanes are made from aluminum. certain beverages are also. aluminum is cheaper and lighter. the biggest problem is the amount of electricity that it takes to make aluminum

- Q: What is the lifespan of aluminum sheets?

- The lifespan of aluminum sheets can vary depending on various factors such as their usage, environment, and maintenance. However, when properly cared for, aluminum sheets can last for decades or even a lifetime due to their inherent resistance to corrosion and durability.

- Q: This is kind of odd, but if a volcano erupted and the lava dripped into an aluminum can, would the can melt? Would the lava harden and cool in it?

- Aluminum cans melt at about 1220 F. Lava is about 1300F to 2400F. The can would melt into the lava.

- Q: Are aluminum sheets suitable for roofing systems?

- Yes, aluminum sheets are suitable for roofing systems. They are lightweight, durable, corrosion-resistant, and can withstand harsh weather conditions. Additionally, aluminum sheets have a long lifespan, require minimal maintenance, and are eco-friendly, making them a popular choice for roofing in many applications.

- Q: How is an aluminum sheet manufactured?

- An aluminum sheet is manufactured through a process called rolling, where a large ingot of aluminum is heated and passed through a series of rollers to reduce its thickness and increase its length. This continuous rolling process is repeated until the desired thickness is achieved, and the aluminum sheet is then cut into various sizes and shapes.

- Q: Hi,I'm building a tricycle for 2 passengers as well as the rider.My main concern for the structure of the chassis is the junction between the rear and the bike frame. Both structures on their own withstand the weight when made out of aluminium, no need to go for steel. But what about that junction? Will aluminium have a propensity to buckle? should i used double tubing or a fork design? I suppose the shape and caliber of the tube also comes into play.Lastly, which of a tube or cylindrical rod is stronger?ThanksAddendum: I'm looking at aluminium because it's cheaper and for weight reduction in the vehicle.

- You cannot weld steel to aluminum with traditional arc welding techniques. It can only be done with explosion or friction welding. I doubt either of these processes will be utilized on a trike frame as they would be cost prohibitive for low production runs. Are you an experienced aluminum welder, or will you be using one? If not, I'd suggest using steel tubing. Steel is much more forgiving during the welding process. It is stronger too; although on the downside, it is heavier. As for your design, it is very difficult to follow your description without a picture. I would be remiss to suggest something with my current, limited understanding. As far as tubing and solid rod are concerned, for the same weight, the tubing will be stronger because it has its mass located away from the center. This will give it much more structural rigidity to resist bending. Now solid rod of the same diameter is stronger than tube, but very heavy. I would think you should be able to use tubing for everything. Maybe thicker or even larger tubes for the areas of high stress concentration such as the area you ask about. If you go with the aluminum, good luck welding it. While it certainly can be done, it takes a great deal more experienced of a welder to perform this operation successfully.

- Q: Are the aluminum sheets suitable for manufacturing architectural ceiling panels?

- Yes, aluminum sheets are suitable for manufacturing architectural ceiling panels. Aluminum is known for its durability, lightweight nature, and resistance to corrosion, making it an ideal material for architectural applications. It can be easily shaped and formed into various panel designs and sizes, offering flexibility in creating unique ceiling designs. Additionally, aluminum sheets are available in different finishes and colors, allowing for customization to meet specific design requirements. Overall, aluminum sheets provide a cost-effective and aesthetically pleasing solution for manufacturing architectural ceiling panels.

- Q: What is the fatigue limit of aluminum sheets?

- The fatigue limit of aluminum sheets varies depending on various factors such as the alloy, thickness, and surface condition. However, aluminum alloys generally exhibit a relatively high fatigue limit compared to other materials, making them suitable for applications where cyclic loading is involved.

- Q: How do you calculate the weight of an aluminum sheet?

- To calculate the weight of an aluminum sheet, you need to consider its dimensions (length, width, and thickness) and the density of aluminum. First, measure the length, width, and thickness of the aluminum sheet in inches or millimeters. Make sure to use the same unit of measurement throughout the calculation. Next, convert the dimensions to feet or meters if necessary. For example, if the dimensions are in inches, divide each value by 12 to convert it to feet. Multiply the length, width, and thickness together to find the volume of the aluminum sheet. If the dimensions are in different units, convert them to the same unit before multiplying. Then, look up the density of aluminum. The density of aluminum is approximately 2.7 grams per cubic centimeter or 2700 kilograms per cubic meter. Convert the volume of the aluminum sheet to the same unit as the density. For example, if the density is in kilograms per cubic meter and the volume is in cubic feet, convert the volume to cubic meters by multiplying it by 0.0283. Finally, multiply the volume of the aluminum sheet by the density of aluminum to get the weight of the sheet. The result will be in grams or kilograms if the density was in grams per cubic centimeter, or in kilograms or metric tons if the density was in kilograms per cubic meter. It's important to note that this calculation assumes a uniform thickness throughout the aluminum sheet. If the sheet has varying thicknesses, you would need to calculate the weight of each section separately and then sum them up to find the total weight.

- Q: Status of aluminum sheet F

- Status of aluminium plateThe F is free, and the aluminum sheet state is not limited. It is suitable for the products which have no special requirement for the working hardening and the heat treatment conditions in the forming process. The mechanical properties of the products in this state are not specifiedO is an annealed state, that is, a fully soft state, suitable for fully annealed products with minimum strength

Send your message to us

Aluminum Trailer Sheets - 7075 T6 T651 Aluminum Sheet for Moulding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords