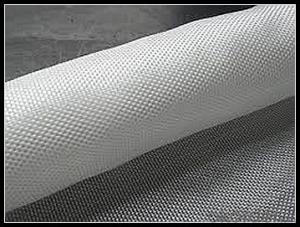

Geotextil Tejido T2400 500g Woven Geotextile Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Function

The main function of these geotextiles is to offer separation, filtration and primarily protection,

• Separation and stabilization in road and railway construction

• Prevention of soil movement in erosion control measures

• Cushioning and protection in many containment projects.

Geotextile

1. short fiber needle punched nonwoven geotextiles (heat set or not) Pet short fiber

2. different color nonwoven geotextile

3. The product has the property of anti-aging, high strength, good flexibility and permeability, filtration, isolation and easy construction

4. It is widely used in areas of the railway, highway, sport venue,dyke,water project construction, tunnel,sea beach,inning,environment protection and so on. It can also used in the reinforcement, separation,filtration,drainage ect.

Detailed Images

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles contribute to climate change adaptation?

- Geotextiles contribute to climate change adaptation by providing effective erosion control and soil stabilization measures. They help prevent soil erosion, which reduces the risk of landslides and other natural disasters caused by heavy rainfall and erosion. Geotextiles also improve water infiltration and drainage, leading to better water management in areas prone to flooding or droughts. Additionally, they promote vegetation growth, which aids in carbon sequestration and reduces greenhouse gas emissions. Overall, geotextiles play a crucial role in mitigating the impacts of climate change and enhancing the resilience of landscapes and infrastructure.

- Q: Are geotextiles suitable for use in geocell mattress systems?

- Yes, geotextiles are suitable for use in geocell mattress systems. Geotextiles are commonly used as a separation and filtration layer in geocell mattress systems to prevent soil migration, enhance drainage, and provide stability. They help distribute loads evenly and improve the overall performance of the geocell mattress system.

- Q: How do geotextiles prevent soil contamination?

- Geotextiles prevent soil contamination by acting as a barrier that separates the soil from potentially harmful substances, such as pollutants or contaminants. It helps to filter and retain these substances, preventing them from leaching into the soil and affecting its quality. Geotextiles also aid in erosion control, reducing the risk of soil contamination caused by sediment runoff.

- Q: What are the different geotextile permeability testing methods?

- Some of the different geotextile permeability testing methods include the constant head method, falling head method, and the variable head method. These methods involve measuring the flow of water through the geotextile under different conditions to determine its permeability.

- Q: What are the factors to consider when installing geotextiles?

- When installing geotextiles, there are several factors to consider. These include the site conditions, the type and quality of the geotextile material, the required strength and permeability characteristics, the installation method, and the long-term performance expectations. Additionally, factors such as the potential for soil erosion, the presence of groundwater, and the desired lifespan of the geotextile should also be taken into account. Proper consideration of these factors ensures that the geotextiles are installed effectively and provide the desired benefits for the intended application.

- Q: What is the role of geotextiles in road construction?

- Geotextiles play a crucial role in road construction by providing reinforcement, filtration, separation, and erosion control. They act as a strong and durable layer between the subgrade and the road surface, distributing loads and preventing soil movement. Geotextiles also filter out fine particles, preventing clogging and maintaining proper drainage. Furthermore, they separate different layers of the road, preventing the intermixing of materials. Overall, geotextiles enhance the longevity and stability of roads, reducing maintenance costs and ensuring safer transportation infrastructure.

- Q: What are the physical properties of geotextiles?

- Geotextiles are engineered fabrics with diverse physical properties. They are typically lightweight, flexible, and permeable. Geotextiles can have varying levels of tensile strength, puncture resistance, and abrasion resistance depending on their intended application. They can be woven or non-woven, with the latter being more commonly used in geotechnical applications. Additionally, geotextiles exhibit good resistance to UV degradation, chemicals, and biological degradation.

- Q: How do geotextiles improve the performance of embankments?

- Geotextiles improve the performance of embankments by providing reinforcement, filtration, and separation. They prevent the intermixing of different soil layers by acting as a barrier, thus enhancing the stability and reducing the settlement of the embankment. Additionally, geotextiles allow for the efficient drainage of water, preventing the buildup of excess pore pressure that could potentially lead to embankment failure.

- Q: Ask geotextile factory in the use of geotextile aperture detector detection method which?

- Hello, geotextile detection method in GB / T and GB / T geotextile aperture in the introduction, you can look at these two standards. The first is geotextile pore size detection wet sieve method, the second is geotextile aperture detection dry sieve method. As the name suggests the first of these two methods is the participation of water, the other is basically the same, are placed in a single layer of geotextile standard small particles, through the vibration to detect the size of the leakage of particles to determine the geotextile pore size size. The difference is that the first standard in the need for continuous water on the particles, so the calculation method are also different. Specific detailed distinctions You can search these two criteria separately.

- Q: Geotextile construction inspection batch ye do?

- Plastic woven category: the same formula, the same specifications of 100,000 square meters of products for a group; less than 100,000 square meters, the actual number of a batch. Non-woven geotextiles: the same frequency of production of the same specifications for a number of products; batch volume can be accumulated 100 volumes for a group, but the week is still less than 100 volumes of output, then with a group of output. Plastic woven cloth: batch as a unit, each batch of products randomly take 3 volumes as a sample geotextile categories: each batch of products randomly selected 2% to 3%, but not less than 2 volumes. Sample requirements: the whole width, length 3m or more, the sample can be rolled up, but can not be folded.

Send your message to us

Geotextil Tejido T2400 500g Woven Geotextile Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords