4x8 Sheets of Aluminum 090 Thick for Building Curtain Walls - Color Coating Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coating Aluminium Sheet for Building Curtain Walls

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | 0.03MM-3.0MM |

WIDTH | 30mm-1700mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE ,PVDF , EPOXY,16-25MICRON PAINTING THICK, MAX 40MICRONS |

STANDARD | GB/T 17748-1999 |

2. Application of Color Coating Aluminium Sheet for Building Curtain Walls

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coating Aluminium Sheet for Building Curtain Walls

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

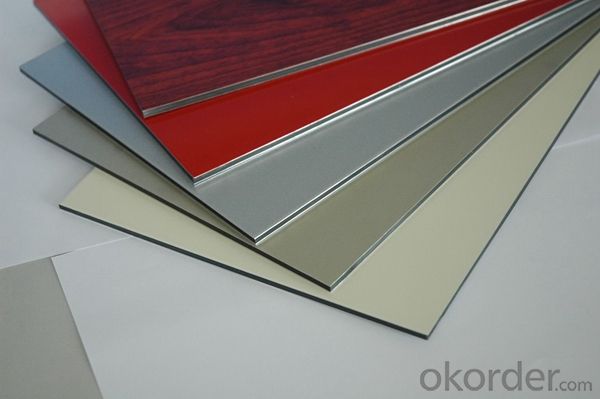

5. Image of Color Coating Aluminium Sheet for Building Curtain Walls

6. Package and shipping of Color Coating Aluminium Sheet for Building Curtain Walls

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Is it possible to substitute traditional wooden windows and doors with aluminum sheets?

- <p>Yes, you can use aluminum sheets to replace traditional wooden windows and doors. Aluminum is a popular choice due to its durability, low maintenance, and resistance to weather and pests. It also offers good thermal performance and can be designed to mimic the appearance of wood. However, it's important to consider factors like insulation, cost, and the specific design requirements of your project before making the switch.</p>

- Q: This question asks for an overview of the various types of coatings applied to aluminum profiles used in exterior cladding systems.

- <p>Aluminum profiles for exterior cladding are often coated to enhance their durability, weather resistance, and aesthetic appeal. Common types of coatings include: 1. Anodizing, which creates a protective oxide layer on the aluminum surface. 2. Powder coating, a popular method that provides a durable and colorful finish. 3. Fluorocarbon coating, known for its excellent weathering and UV resistance. 4. PVDF (Polyvinylidene Fluoride) coating, highly resistant to chemicals and suitable for marine environments. 5. Electrophoretic coating, which offers a smooth, even finish. 6. Hot-dip galvanizing, a process that coats aluminum with a protective layer of zinc. Each coating type has specific advantages and is chosen based on the performance requirements and environmental conditions of the project.</p>

- Q: where can I sell aluminum tabs from aluminum cans in Palmdale, Califronia?

- For okorder /

- Q: What are the environmental benefits of using aluminum sheets?

- There are several environmental benefits of using aluminum sheets. Firstly, aluminum is a highly recyclable material, meaning that it can be reused repeatedly without losing its quality. This reduces the need for mining and extraction of new aluminum, conserving natural resources and minimizing the environmental impact of the production process. Additionally, aluminum has a lower carbon footprint compared to other metals, as it requires less energy to produce. Moreover, aluminum is lightweight, which reduces fuel consumption during transportation, leading to lower greenhouse gas emissions. Overall, using aluminum sheets helps in promoting a more sustainable and eco-friendly approach to manufacturing and construction.

- Q: Are aluminum sheets suitable for furniture manufacturing?

- Yes, aluminum sheets are suitable for furniture manufacturing. Aluminum is a lightweight and versatile material that offers numerous advantages for furniture production. It is corrosion-resistant, making it ideal for both indoor and outdoor furniture. Additionally, aluminum has a high strength-to-weight ratio, allowing for the creation of sturdy and durable furniture pieces. It is also easy to work with, as it can be cut, bent, and welded into various shapes and designs. Moreover, aluminum can be finished with different coatings or paints to enhance its appearance and protect it from wear and tear. Overall, aluminum sheets are a viable option for furniture manufacturing due to their strength, versatility, and aesthetic appeal.

- Q: Why must the aluminum oxide be electrolyzed in a molten cryolite solution?

- To electrolyse aluminium oxide, it has to be molten. However, the melting point of Al2O3 is extremely high ( 1000°C), and that would make the electrolysis very inefficient. However, Al2O3 dissolves in cryolite at much lower temperatures (lower than 900°C), which makes it a much more viable process.

- Q: Is it possible to use aluminum sheets as a material for interior wall decoration?

- <p>Yes, aluminum sheets can be used for interior wall cladding. They are lightweight, durable, and resistant to corrosion, making them suitable for various interior applications. Aluminum sheets are also easy to install and maintain, and they can be painted or finished in various ways to match different design styles. However, it's important to ensure proper installation and adherence to local building codes and regulations.</p>

- Q: Are the aluminum sheets suitable for manufacturing architectural ceiling panels?

- Yes, aluminum sheets are suitable for manufacturing architectural ceiling panels due to their lightweight properties, durability, and corrosion resistance. Additionally, aluminum sheets can be easily formed, cut, and fabricated into various shapes and designs, making them a popular choice for ceiling panels in architectural applications.

- Q: Is aluminum sheet corrosion-resistant?

- Indeed, aluminum sheet exhibits remarkable resistance to corrosion. When aluminum comes into contact with oxygen in the atmosphere, it develops a protective oxide layer that effectively hinders any further corrosion. This oxide layer acts as a shield, safeguarding the underlying metal against moisture, chemicals, and other detrimental corrosive agents. Moreover, aluminum demonstrates exceptional resistance to corrosion induced by saltwater, rendering it highly favored for marine applications. Nevertheless, it is crucial to acknowledge that specific circumstances, such as exposure to acidic or alkaline surroundings, can still induce corrosion on aluminum surfaces if not adequately preserved or shielded.

- Q: What does aluminum plate "1060-H24" mean?

- Two, second, Arabia number 0, said the original alloy, such as 1, said the original alloy after a modification, 2 means that the original alloy after two modificationsThree, third and four 60 two Arabia data represent the value behind pure aluminum content of 99% per cent in pure aluminum, said 60 pure aluminum aluminum content of 99.60%, as the standard 1050 indicates the aluminum content of pure aluminum, 99.50% of the 1070 said that the aluminum content of 99.70% pure aluminum alloy in the back. In two the number of Arabia aluminum has no special meaning, is only used to identify the different alloys in the same group, said its second modifications.

Send your message to us

4x8 Sheets of Aluminum 090 Thick for Building Curtain Walls - Color Coating Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords