3mm SBS Elastomer Modified-bitumen Waterproof Membrane

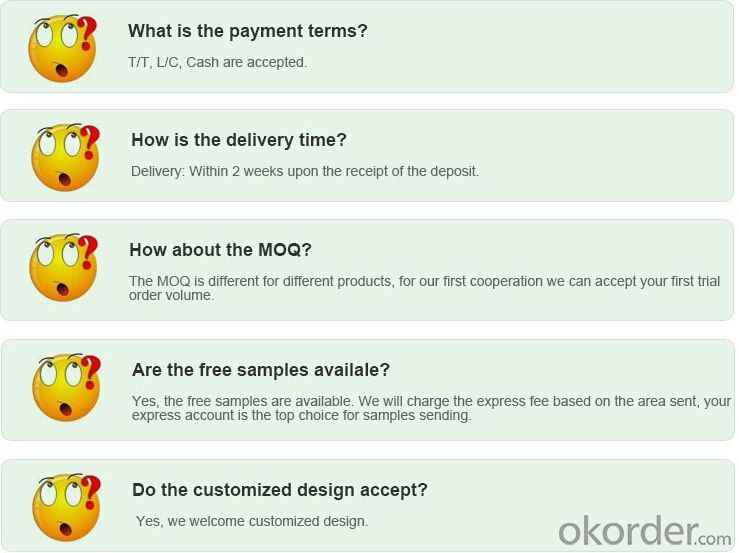

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product description:

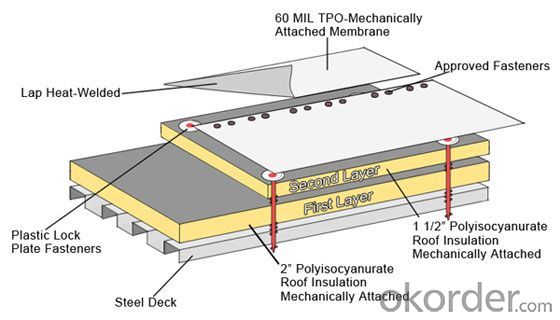

sbs waterproof membrane take the “Skin” type waterproof thought, according to the features of construction site, on the basis of width elastomeric modified bitumen waterproofing membrane, combining with features of wet-application self-adhesive membrane, use advanced equipment to produce 2 meters width that WP-SBS wet-application width elastomeric modified bitumen waterproofing membrane (Hereinafter referred to: WP-SBS membrane).WP-SBS is made of bitumen modified with Styrene-Butadiene- Styrene (SBS)as dipping and painting. Its upper surface covers PE membrane and color sand or schist, and lower surface is made of isolation material. Products correspond to the national standards GB18242-2008(elastomeric modified bitumen waterproofing membrane), paste by cement or cement mortar, and construct on the wet base, achieving tight and full adhesion with substrates, eliminating fluid-channeling layer, all above contribute to making a reliable “Skin” type waterproof system, which is a breakthrough innovation in ordinary modified bitumen membrane.

Characteristic

1.Good impermeability

2.Possess good tensile strength, elongation and size stability which could be well suited the substrate distortion and crack.

3.Good performance in anti-strength, anti-resistance , anti-erosion, anti-mildew, anti-weathering

4.SBS modified bitumen membrane is specially being applied in the cold area with low temperature, while APP modified bitumen membrane is applied in the area with high temperature.

5.Convenient installation

Applicable scope:

It is widely used for civil building roofing, underground, bridge, parking, pool, tunnel in the line of waterproofing and dampproofing, especially for the building under high temperature.

Application

The needle-punched polyester is widely used as the carrier for waterproofing membrane production. The membrane made withneedle-punched polyester matis widely used for: Construction waterproofing; Moisture-proof in roof engineering, underground engineering, indoor ground, etc;Corrosion resistance for water pool or building bases.

Our Services

1.If you need some advises for the waterproof construction, we have the best engineer to serve you.

2.We send the free samples to you by freight collect.

3.We will guarantee the quality and the competitive price.

4.We will give you the best packaging and safe shipping.

5.If any problem, we will always be right here waiting for you.

Packaging & Shipping

| Packing | Woven bag/PE bag packing or as customer request |

| Shipping | FOB Changsha,customized shipping terms and oppointed port accepted |

Technical parameter

| Item | Specifications | ||||||||

| Geotextile Unit Weight (g/m²) | 300 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | |

| Geomembrane Thickness (mm) | 0.25-0.35 | 0.30-0.50 | |||||||

| Nominal Fracture Strength (KN/m) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Breaking Strength (KN/m,≥,LD/TD) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Standard Intensity Corresponding Elongation Rate (%) | 30~100 | ||||||||

| CBR Burst Strength (KN,≥) | 0.70 | 1.50 | 1.90 | 2.20 | 2.50 | 2.80 | 3.00 | 3.20 | |

| Longitudinal Tear Strength (KN,≥) | 0.05 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| Hydrostatic Pressve (Mpa) | See List Below | ||||||||

| Peel Strength (N/cm,≥) | 6 | ||||||||

| Vertical Permeability Coefficient (cm/s) | According to design or contract mentioned. | ||||||||

| Width Variation (%) | -1.00 | ||||||||

| Item | Geomembrane Thickness (mm) | ||||||||

| 0.20 | 0.30 | 0.40 | 0.50 | 0.60 | 0.70 | 0.80 | 1.00 | ||

| Hydrostatic Pressve (Mpa) | One geotextiles with one geomembrane | 0.40 | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 |

| Two geotextiles with one geomembrane | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 | 1.80 | |

Professional test machines ensure the products qualified roduct certifications

roduct certifications

Inquiry Note

How to send an effective inquiry for saving your time?

product show

FAQ

- Q: Can a waterproofing membrane be used in government or municipal projects?

- Yes, a waterproofing membrane can be used in government or municipal projects. In fact, it is a common practice to use waterproofing membranes in various infrastructure projects such as bridges, tunnels, parking structures, and government buildings. These membranes provide a reliable and durable solution to prevent water infiltration, protect the structural integrity of the project, and extend its lifespan. Additionally, waterproofing membranes can meet the necessary regulations and standards required for government or municipal projects.

- Q: It is good for black roof with waterproof paper

- No film or PE film (black surface) coil is generally not used for the roof; if the roof is often on the need to lay in the coil above the 5 cm thick cement mortar to do the protective layer or the choice of sand and shale surface waterproof Coil. Lough membrane (silver surface) The role of the membrane to play the radiation can be used directly for the roof without any protection.

- Q: Are waterproofing membranes suitable for rooftop gardens?

- Yes, waterproofing membranes are suitable for rooftop gardens. They provide an effective barrier against water leakage and prevent any potential damage to the structure below. Additionally, these membranes also protect the plants and vegetation in the rooftop garden from excessive moisture, ensuring their healthy growth.

- Q: Does a waterproofing membrane require any special cleaning or maintenance procedures?

- Special cleaning and maintenance procedures are necessary for a waterproofing membrane. Although it is designed to resist water and other elements, regular maintenance is crucial to ensure its durability and effectiveness. The specific procedures for cleaning and maintenance may vary depending on the type of waterproofing membrane used. However, it is generally advised to keep the membrane clean and free from debris, such as leaves, dirt, or other foreign objects. This can be achieved by sweeping or gently washing the surface with water and, if needed, a mild detergent. Furthermore, it is essential to regularly inspect the membrane for any signs of damage, such as tears, cracks, or loose seams. If any issues are detected, they should be promptly addressed to prevent water infiltration and further harm. In certain cases, the manufacturer or installer of the waterproofing membrane may recommend specialized cleaning products or treatments. It is important to adhere to their guidelines and recommendations to ensure proper care and maintenance for the specific membrane used. Overall, regular cleaning and maintenance of a waterproofing membrane will prolong its lifespan and guarantee its continued effectiveness in safeguarding the underlying structure from water damage.

- Q: Can a waterproofing membrane be used in renovation or retrofitting projects?

- Yes, a waterproofing membrane can definitely be used in renovation or retrofitting projects. This membrane is designed to create a barrier against water penetration, which is essential in protecting the building structure from moisture damage. By applying a waterproofing membrane during renovation or retrofitting, it helps prevent water infiltration, dampness, mold growth, and potential structural issues.

- Q: Can a waterproofing membrane be used in earthquake-prone areas?

- Yes, a waterproofing membrane can be used in earthquake-prone areas. Waterproofing membranes are designed to provide a barrier against moisture penetration, and they can also offer some degree of flexibility and elasticity. This allows them to withstand the movement and vibrations caused by earthquakes, helping to protect the structure from water damage and potential leaks. However, it is important to ensure that the chosen membrane meets the specific requirements and standards for earthquake-prone areas to ensure its effectiveness and durability.

- Q: Can waterproofing membranes be used on parking decks?

- Yes, waterproofing membranes can be used on parking decks. Waterproofing membranes are commonly used in construction projects to prevent water penetration, and they are particularly useful for protecting structures such as parking decks from moisture damage. These membranes are applied to the surface of the deck, providing a barrier against water and preventing potential issues like leaks, cracks, and deterioration caused by moisture.

- Q: Can a waterproofing membrane be used on brick surfaces?

- Indeed, brick surfaces can benefit from the application of a waterproofing membrane. These membranes have been specifically designed to create a barrier that effectively stops water from infiltrating. Notably, they have the versatility to be applied on various surfaces, including brick. By applying a waterproofing membrane to a brick surface, the risk of water damage is significantly reduced. This means that issues such as moisture seepage, which can lead to brick deterioration or the growth of mold, can be prevented. To ensure optimal results, it is crucial to select a waterproofing membrane that is compatible with brick and to closely adhere to the manufacturer's instructions during application. Seeking professional guidance is also advisable in order to choose and apply the most suitable membrane based on the specific requirements and conditions of the brick surface.

- Q: Are waterproofing membranes resistant to chemicals?

- Yes, waterproofing membranes are generally resistant to chemicals. These membranes are designed to provide a protective barrier against water infiltration and are typically made from materials such as PVC, TPO, or EPDM which have excellent chemical resistance properties. They are specifically engineered to withstand exposure to various chemicals, including acids, alkalis, solvents, and oils, without deteriorating or being damaged. This chemical resistance ensures that waterproofing membranes can maintain their integrity and effectiveness in environments where chemical exposure is common, such as industrial settings, laboratories, or chemical storage areas. However, it is important to note that the specific chemical resistance capabilities can vary depending on the type and quality of the waterproofing membrane, so it is crucial to choose the appropriate membrane that suits the specific chemical exposure requirements of the project.

- Q: Can a waterproofing membrane be used in agricultural structures?

- In agricultural structures, like barns, greenhouses, and storage facilities, it is possible to utilize a waterproofing membrane. These structures often necessitate protection against moisture and water harm. A waterproofing membrane is a robust and flexible substance that can be applied to diverse surfaces such as roofs, walls, and floors to obstruct water infiltration. It functions as a barrier, stopping water from penetrating the structure and causing destruction to the building materials, equipment, and stored crops. Moreover, a waterproofing membrane can also assist in regulating the temperature and humidity levels within the agricultural structure, generating a more controlled and ideal environment for crops, livestock, and equipment. In summary, the utilization of a waterproofing membrane in agricultural structures can guarantee the durability and functionality of the building while safeguarding the valuable assets inside.

Send your message to us

3mm SBS Elastomer Modified-bitumen Waterproof Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords