304 Stainless Steel Sheets building materials using 2b sus

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM

Technique:

Cold Rolled

Shape:

Square

Surface Treatment:

Oiled

Steel Grade:

300 Series

Certification:

SGS

Thickness:

1.2

Width:

1000

Length:

2000

Net Weight:

21

Product Description

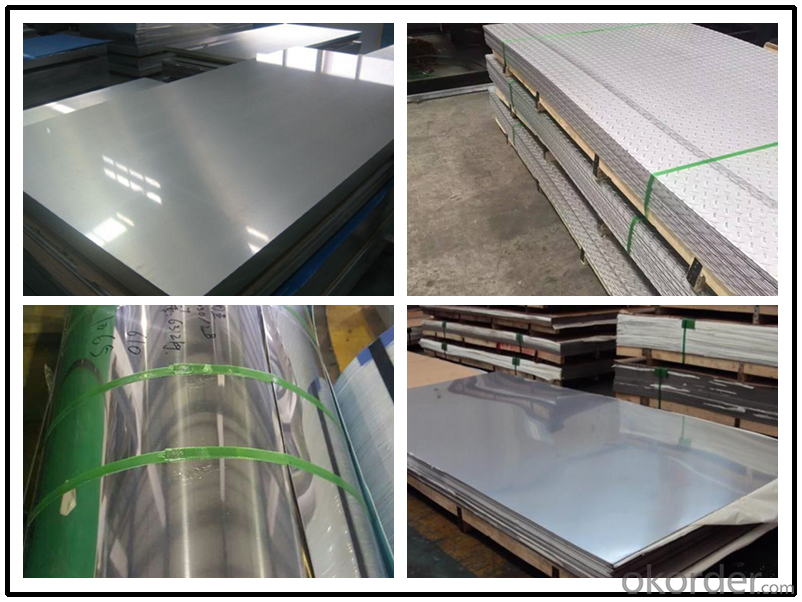

building materials using 2b sus 304 stainless steel sheets

| Type | 304 Stainless steel sheet |

| Name | building materials using 2b sus 304 stainless steel sheets |

| Thickness | 0.3 mm - 50mm |

| Size | 1000*2000mm, 1219*2438mm, 1219*3048mm, customized Max.width 1500mm |

| SS Grade | 304,316, 201,430 etc. |

| Finish | Mirror +etch |

| Avaible finishes | No.1 Hairline, Mirror, Etching, Embossed, Vibration, Sandblast, Combination, lamination etc. |

| Origin | Huaxiang shandong |

| Packing way | PVC+ waterproof paper + strong sea-worthy wooden package |

Chemical composition | ||||

| Grade | STS304 | STS 316 | STS430 | STS201 |

| Elong(10%) | Above 40 | 30MIN | Above 22 | 50-60 |

| Hardness | ≤200HV | ≤200HV | Below 200 | HRB100,HV 230 |

| Cr(%) | 18-20 | 16-18 | 16-18 | 16-18 |

| Ni(%) | 8-10 | 10-14 | ≤0.60% | 0.5-1.5 |

| C(%) | ≤0.08 | ≤0.07 | ≤0.12% | ≤0.15 |

Detailed Images

Packaging & Shipping

Application

- Q: Can stainless steel sheets be used for power generation equipment?

- Stainless steel sheets are indeed applicable for power generation equipment. With its versatility, stainless steel possesses a range of advantageous qualities specifically tailored for power generation applications. Its corrosion resistance is exceptional, a paramount characteristic for equipment that comes into contact with water, steam, or other corrosive substances. Moreover, stainless steel exhibits remarkable strength and durability, enabling it to withstand the elevated temperatures and pressures frequently encountered in power generation systems. Another notable attribute is its proficiency as an electrical conductor, rendering it suitable for electrical components and connections within the equipment. Consequently, stainless steel sheets are widely employed in the construction of power generation equipment, including turbines, boilers, heat exchangers, and exhaust systems.

- Q: How do you prevent pitting on stainless steel sheets?

- To prevent pitting on stainless steel sheets, there are several steps you can take: 1. Ensure proper cleaning and maintenance: It is important to regularly clean the stainless steel sheets using mild soap or a non-abrasive cleaning solution. Avoid using harsh chemicals, bleach, or abrasive cleaners as they can harm the protective layer on the surface. After cleaning, make sure to thoroughly rinse and dry the sheets to eliminate any residue that could lead to pitting. 2. Avoid contact with corrosive substances: Although stainless steel is highly resistant to corrosion, prolonged exposure to certain chemicals or substances can still cause pitting. It is advisable to avoid contact with chloride-based cleaners, strong acids, or solutions containing high concentrations of salt. If accidental contact occurs, immediately rinse the sheets with clean water and dry them thoroughly. 3. Protect against physical damage: Pitting can occur on stainless steel sheets if they get scratched or damaged. It is crucial to handle and install the sheets with care to prevent any sharp or abrasive objects from scratching the surface. During transportation and storage, consider using protective films or covers to minimize the risk of physical damage. 4. Apply a protective coating: To enhance the natural corrosion resistance of stainless steel and reduce the risk of pitting, you may want to consider applying a protective coating or passivating treatment to the sheets. It is recommended to consult with a professional or supplier to determine the most suitable coating or treatment for your specific stainless steel grade and application. 5. Conduct regular inspection and maintenance: It is important to periodically inspect the stainless steel sheets for any signs of pitting or corrosion. Promptly address any issues by cleaning, repairing, or replacing the affected areas. Regular maintenance and inspection will help identify potential problems early on and prevent them from worsening. By following these preventive measures, you can minimize the occurrence of pitting on stainless steel sheets, extend their lifespan, and maintain their aesthetic appeal.

- Q: Are stainless steel sheets suitable for desalination plants?

- Indeed, desalination plants find stainless steel sheets to be quite appropriate. Stainless steel exhibits remarkable resistance against corrosion and can endure the severe circumstances encountered in such plants, such as contact with saltwater and exposure to high temperatures. Its exceptional durability and mechanical characteristics render it an ideal material for multiple components in desalination plants, such as piping, heat exchangers, and tanks. Furthermore, stainless steel possesses commendable hygiene properties, rendering it suitable for desalination plants that necessitate stringent cleanliness standards. Moreover, the fabrication and installation of stainless steel sheets are effortless, allowing for efficient construction and maintenance procedures in desalination plants.

- Q: Are stainless steel sheets suitable for welding or fabrication?

- Yes, stainless steel sheets are suitable for welding and fabrication. Stainless steel has excellent weldability, which means it can be easily fused together using various welding techniques such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding. It also has good formability, allowing it to be easily shaped and fabricated into different structures or components. Additionally, stainless steel sheets offer high strength and corrosion resistance, making them a popular choice in industries such as construction, automotive, and manufacturing. Overall, stainless steel sheets are a versatile and reliable material for welding and fabrication applications.

- Q: How do I install stainless steel sheets?

- To install stainless steel sheets, start by measuring and marking the area where the sheets will be installed. Next, ensure the surface is clean and free from dust or debris. Apply a strong adhesive or use screws to secure the sheets to the surface, making sure they are aligned properly. If needed, cut the sheets to fit using appropriate tools such as a metal shear or circular saw with a metal-cutting blade. Finally, ensure all edges and seams are properly sealed to prevent water or moisture infiltration.

- Q: Seeking stainless steel plate 304 material and 304j material what is the difference?

- 304J1 is a kind of material in stainless steel plate. Is 304 of copper containing material, deep drawing performance better than 304, mainly for deep processing purposes, but also belong to the nickel series.

- Q: Are stainless steel sheets suitable for chemical tanks?

- Yes, stainless steel sheets are suitable for chemical tanks. Stainless steel is highly resistant to corrosion and can withstand the corrosive effects of many chemicals. It is also durable, easy to clean, and has excellent strength properties, making it an ideal material for chemical tanks.

- Q: Can stainless steel sheets be used for food packaging equipment?

- Yes, stainless steel sheets can be used for food packaging equipment. Stainless steel is a common material choice for food packaging equipment due to its durability, corrosion resistance, and hygienic properties. It is able to withstand the rigorous demands of food packaging processes and ensure the safety and quality of the packaged food.

- Q: How do stainless steel sheets compare to other materials?

- Various industries favor stainless steel sheets due to their numerous advantages over other materials. The exceptional durability and strength of stainless steel are well-known. It can endure high temperatures, pressure, and corrosion, making it suitable for a wide range of applications. Moreover, this durability ensures a longer lifespan and reduces the need for frequent replacements, ultimately saving time and money. Stainless steel sheets also possess excellent resistance to corrosion and rust. This property is particularly crucial in environments with high humidity or exposure to chemicals, as it prevents degradation and maintains the material's integrity. Unlike aluminum or carbon steel, which may require protective coatings or regular maintenance to achieve similar levels of corrosion resistance, stainless steel sheets naturally possess this quality. Furthermore, stainless steel sheets boast a clean and smooth surface finish, making them visually pleasing and easy to clean. This attribute is of utmost importance in industries such as food processing, pharmaceuticals, and healthcare, where hygiene and cleanliness are paramount. Stainless steel sheets also offer versatility in terms of fabrication and customization. They can be easily formed, welded, and shaped into different sizes and configurations, allowing for a wide range of applications. This versatility makes stainless steel sheets suitable for architectural, automotive, and industrial uses. Lastly, stainless steel is environmentally friendly. It is 100% recyclable, meaning it can be melted down and reused without any loss in quality or performance. This recyclability reduces the demand for new materials and minimizes the environmental impact associated with manufacturing processes. In summary, stainless steel sheets surpass other materials in terms of durability, corrosion resistance, cleanliness, versatility, and environmental sustainability. These qualities establish stainless steel sheets as the superior choice for various industries and applications.

- Q: Are stainless steel sheets suitable for solar panel frames?

- Yes, stainless steel sheets are suitable for solar panel frames. Stainless steel is known for its durability, corrosion resistance, and ability to withstand extreme weather conditions, making it a reliable material for supporting and protecting solar panels. Its strength-to-weight ratio also makes it ideal for constructing lightweight yet sturdy frames that can withstand the rigors of outdoor installations.

Send your message to us

304 Stainless Steel Sheets building materials using 2b sus

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords