Stainless Steel Plate 304L/sus 304L 2b CHINA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Overviews

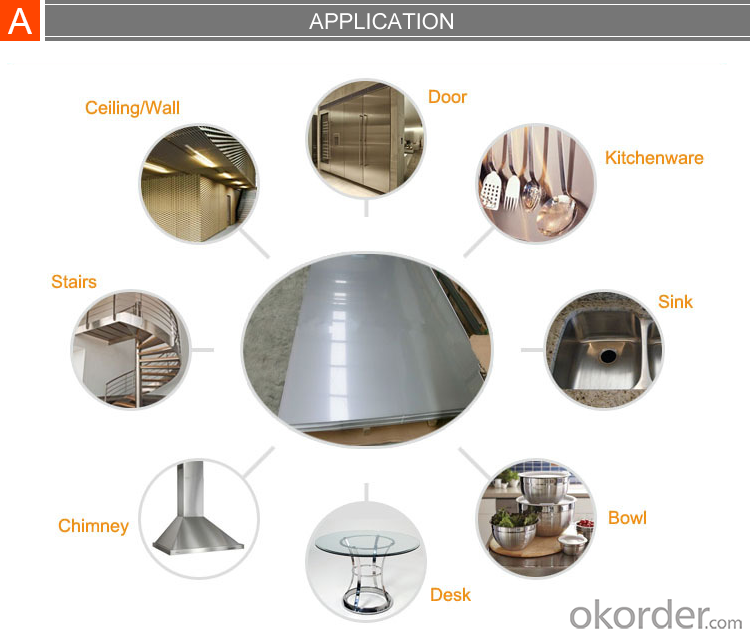

SUS 304 2B/STAINLESS STEEL PLATE 304

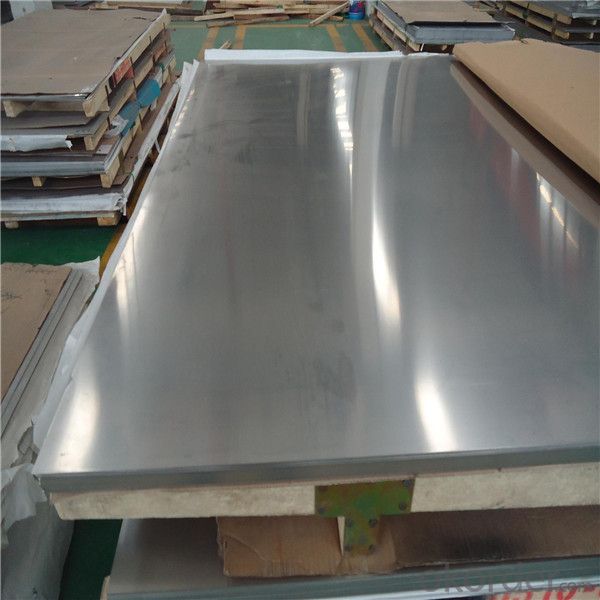

LENGTH: 2000-3000mm, customized

WIDTH: 1000-1500mm, customized

THICKNESS: 0.3-20mm, customized

Certification: SGS, ISO

Lead time: 10-15 DAYS

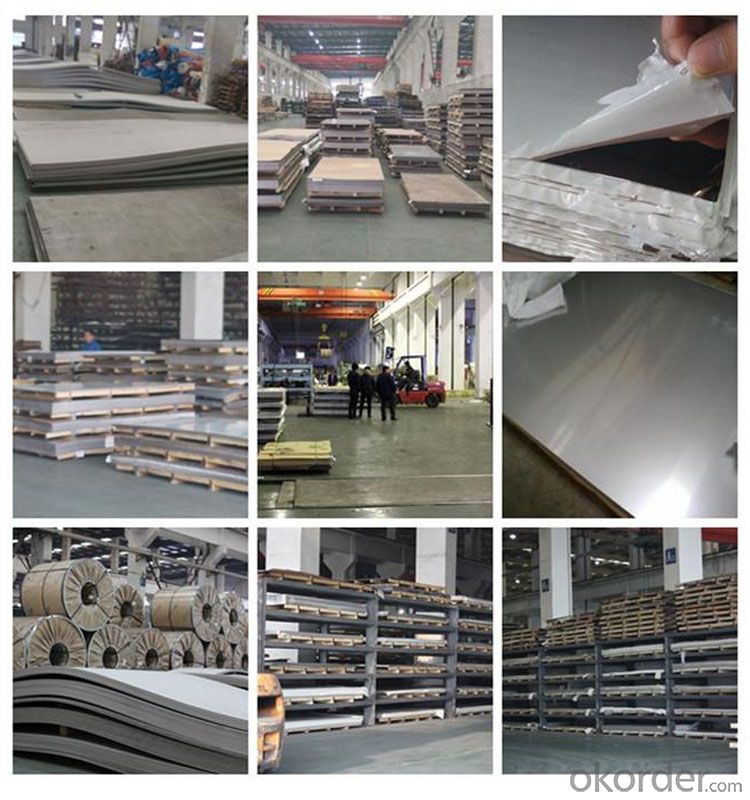

Capacity: 2000 ton/month

Adevantage: we ensure the best quality and provid the best service, the most important is we give you the best price!!!

Packaging & Shipping

packaging: We provide woven bag and wooden case or can be customizd and standerd export package.

Our Services

we provide the best price

we are specialized in stainless steel, we provide the best quality ever

we have strong quality control system: Raw material control/process control/component quality control/finished product quality inspection/mass production spot check/inspection company check

we provide the most efficient and effective work. (Quotations will be sent within one business day)

we provide the most efficiently lead time

we quickly responese for any questions and provide solutions effectively

large inventory

- Q: What is the weight of a stainless steel sheet?

- The weight of a stainless steel sheet depends on its dimensions (length, width, and thickness).

- Q: Are stainless steel sheets suitable for cleanroom applications?

- Yes, stainless steel sheets are suitable for cleanroom applications. Stainless steel has excellent corrosion resistance, which is important in cleanroom environments where cleanliness and hygiene are crucial. It is also highly durable and easy to clean, making it ideal for maintaining cleanliness standards in cleanrooms. Additionally, stainless steel is non-porous, which means it does not absorb contaminants and can be easily sanitized. It is also resistant to chemicals, making it suitable for cleanroom applications where strong disinfectants or cleaning agents may be used. Overall, stainless steel sheets offer a reliable and hygienic surface for cleanroom applications.

- Q: Are stainless steel sheets suitable for cryogenic storage tanks?

- Yes, stainless steel sheets are suitable for cryogenic storage tanks. Stainless steel is known for its excellent corrosion resistance, which makes it highly suitable for storing low-temperature substances such as liquefied natural gas (LNG), liquid nitrogen, or liquid oxygen. Cryogenic storage tanks require materials that can withstand extreme low temperatures without becoming brittle or losing their strength, and stainless steel meets these requirements. Additionally, stainless steel has good thermal conductivity, which helps in maintaining the desired temperature inside the tank. It is also easy to clean and maintain, making it a preferred choice for cryogenic storage tanks in various industries.

- Q: Can stainless steel sheets be used for HVAC systems?

- Yes, stainless steel sheets can be used for HVAC systems. Stainless steel is highly resistant to corrosion and can withstand high temperatures, making it an ideal material for HVAC components such as ductwork, heat exchangers, and exhaust systems. It is also durable and easy to clean, ensuring long-lasting performance in HVAC applications.

- Q: How do you restore the shine or finish on stainless steel sheets?

- To restore the shine or finish on stainless steel sheets, you can start by cleaning the surface with a mixture of warm water and mild detergent. Gently scrub the sheets using a soft sponge or cloth in the direction of the grain to avoid scratching. Rinse thoroughly and dry with a clean cloth. If the shine is still lacking, you can use a stainless steel cleaner or polish specifically designed for the material. Apply the cleaner following the product instructions, again following the grain, and wipe off any excess. This should help restore the shine and finish on your stainless steel sheets.

- Q: Can stainless steel sheets be used for outdoor signage?

- Yes, stainless steel sheets can be used for outdoor signage. Stainless steel is a durable and corrosion-resistant material that can withstand harsh weather conditions and maintain its appearance over time. It is commonly used in outdoor signage due to its ability to resist rust, fading, and damage from exposure to sunlight, rain, snow, and other environmental elements. Additionally, stainless steel sheets can be customized with various finishes, such as brushed or polished, to enhance their visual appeal and make them suitable for any outdoor signage application.

- Q: What is the thickness range available for stainless steel sheets?

- The thickness range available for stainless steel sheets typically varies from 0.4mm to 6mm, depending on the specific requirements and applications.

- Q: Can stainless steel sheets be used in food processing industry?

- Yes, stainless steel sheets are commonly used in the food processing industry due to their hygienic properties, corrosion resistance, and durability. They are suitable for various applications such as food storage, preparation surfaces, equipment, and production areas.

- Q: Are stainless steel sheets recyclable?

- Yes, stainless steel sheets are recyclable. Stainless steel is one of the most recyclable materials in the world, and its properties allow it to be recycled repeatedly without losing its quality or durability.

- Q: Are stainless steel sheets good for oil and gas equipment?

- Yes, stainless steel sheets are highly suitable for oil and gas equipment. Stainless steel has excellent corrosion resistance, high strength, and durability, making it an ideal choice for harsh environments and corrosive substances encountered in the oil and gas industry. Additionally, stainless steel's heat resistance and low maintenance requirements further contribute to its effectiveness in this field.

Send your message to us

Stainless Steel Plate 304L/sus 304L 2b CHINA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords