304 Stainless Steel Sheet with 2B finish

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

304 Stainless Steel Sheet with 2B Finish

Brief introduction

Title:304 Stainless Steel Sheet with 2B Finish

Usage:Construction, Hardware, Home appliances

Advantage:Anti-rust, Low temperature resistance, Widely use.

Deatail of 304 Stainless Steel Sheet with 2B Finish

| Grade | 304 (300 series) | Length | 0-6000mm | T.S(N/mm2) | ≥520 |

Technical Treatment | Cold Rolling | Edge | Mill Edge Slit Edge | EL(%) | ≥40 |

| Surface | 2B | Standard | ASTM, AISI, EN, GB, JIS | HV | ≤200 |

| Thickness | 0.3mm-3.0mm | Brand | TISCO | ||

| Width | 1219mm/1500mm | Y.S(N/mm2) | ≥205 |

Advantage of 304 Stainless Steel Sheet

304 stainless steel is the basic chromium-nickel stainless steel. It combines excellent mechanical properties

with excellent resistance to many corrosive agents encountered in domestic and industrial use.

◎ Non magnetic

◎ Corrosion resistance

◎ Heat resistance

◎ Excellent low-temperature strength

◎ Excellent mechanical properties

Surface of Stainless Steel Sheet

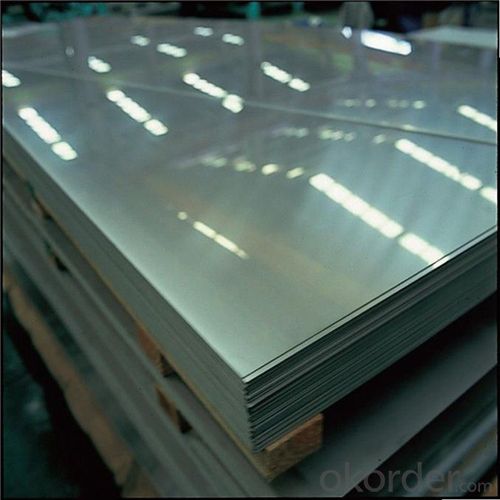

Display of 304 Stainless Steel Sheet with 2B Finish

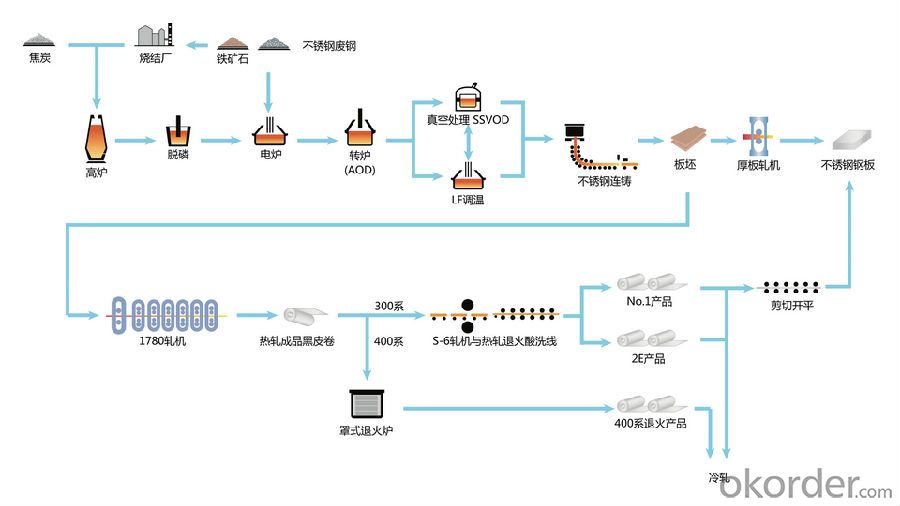

Production of 304 Stainless Steel Sheet with 2B Finish

Package of 304 Stainless Steel Sheet with 2B Finish

Sheets will be covered by water-proof paper first, then use steel strip to fix it onto the pallet.

Application of 304 Stainless Steel Sheet with 2B Finish

Stainless steel sheet has widely usage in kitchen ware, infrastructure, industry, etc.

FAQ

Q: What is MOQ ?

A: 1 Ton

Q: What kind of terms of payment can you accept ?

A: T/T, L/C, Western Union and so on.

Q: Can you provide samples for reference ?

A: Yes,we can arrange the sample with your needed size for free.

Q: Can you provide MTC ?

A: Of course, the MTC is availble for your confirmation of chemical composition and mechanical properties.

- Q: Can stainless steel sheets be used for wall cladding?

- Certainly! Wall cladding can indeed utilize stainless steel sheets. This material, known for its durability and resistance to corrosion, proves to be a fitting selection for cladding purposes. Its sleek and contemporary appearance enhances the aesthetic appeal of walls. Furthermore, stainless steel sheets are effortless to install and maintain, rendering them an exceptional choice for both indoor and outdoor walls. Moreover, they possess remarkable fire resistance and can endure high temperatures, guaranteeing a secure option for wall cladding.

- Q: Can stainless steel sheets be used for wall paneling?

- Certainly! Wall paneling can be done using stainless steel sheets. Stainless steel is a versatile material that is famous for its durability, ability to resist corrosion, and attractive appearance. It is widely used in various applications, including wall paneling in both residential and commercial settings. Installing stainless steel sheets as wall panels is a breeze, giving the space a contemporary and elegant look. Moreover, stainless steel is effortless to clean and maintain, making it a practical choice for wall paneling in areas that require frequent cleaning, such as kitchens and bathrooms. In summary, stainless steel sheets are an excellent choice for wall paneling due to their long-lasting nature, aesthetic appeal, and ease of maintenance.

- Q: Can stainless steel sheets be used for marine propellers?

- Yes, stainless steel sheets can be used for marine propellers. Stainless steel is a popular choice for marine propellers due to its excellent corrosion resistance properties. The high levels of chromium in stainless steel make it resistant to rust and other forms of corrosion, even in saltwater environments. Additionally, stainless steel offers good strength and durability, making it suitable for withstanding the harsh conditions of marine environments. Stainless steel propellers are often preferred for boats and ships as they require less maintenance and have a longer lifespan compared to other materials. However, it is important to choose the appropriate grade of stainless steel for marine propellers to ensure optimal performance and longevity.

- Q: What's the difference between stainless steel 304 and stainless steel 202?

- After pickling of stainless steel, surface color silver finish: chromium nickel stainless steel color white jade is white; chromium stainless steel slightly weak light Ze; CrMnN Stainless steel and chromium nickel stainless steel similar color is slightly lighter. The surface color: stainless steel pickling chrome nickel steel is brownish black brown and white; chromium; chromium manganese nitrogen is black, (these three kinds of color, refers to the oxidation of the heavier color). Cold rolled unannealed chromium nickel stainless steel, silver reflective surface. Stainless steel, except for steel, is usually pickled and white.

- Q: How do I prevent finger marks on stainless steel sheets?

- To prevent finger marks on stainless steel sheets, you can try a few simple steps. Firstly, make sure to clean the sheets regularly using a mild detergent or stainless steel cleaner to remove any existing fingerprints. Next, consider applying a protective coating or film specifically designed for stainless steel surfaces, which can provide a barrier against smudges and fingerprints. Additionally, try to handle the sheets with clean and dry hands to minimize the transfer of oils and dirt. Finally, consider using microfiber or lint-free cloths for cleaning instead of rough materials that can leave scratches or streaks.

- Q: What are the different types of stainless steel sheet surface textures available?

- Some of the different types of stainless steel sheet surface textures available include brushed, mirror, embossed, and patterned.

- Q: Can stainless steel sheets be used in food processing applications?

- Yes, stainless steel sheets can be used in food processing applications. Stainless steel is a popular choice for food processing equipment due to its excellent corrosion resistance, durability, and hygienic properties. It is highly resistant to staining, rusting, and contamination, making it suitable for direct contact with food. Stainless steel sheets are commonly used for surfaces such as countertops, work tables, and food preparation areas in commercial kitchens and food processing facilities. Additionally, stainless steel is easy to clean and maintain, which is crucial in ensuring food safety and compliance with industry regulations.

- Q: Are stainless steel sheets scratch-resistant?

- Yes, stainless steel sheets are generally scratch-resistant. Stainless steel is known for its durability and resistance to scratches, making it an ideal material for various applications, including kitchen appliances, countertops, and decorative purposes. However, it is important to note that while stainless steel is highly resistant to scratches, it is not completely scratch-proof. Sharp objects or abrasive materials can still cause scratches or scuff marks on the surface of stainless steel sheets, especially with excessive force or repeated contact. Regular maintenance and proper care can help minimize the appearance of scratches and keep stainless steel sheets looking their best.

- Q: Can stainless steel sheets be used for elevator interiors?

- Elevator interiors can indeed incorporate stainless steel sheets. Stainless steel proves to be a favored material for elevator interiors due to its durability, aesthetic appeal, and low maintenance. Its resistance to corrosion, scratches, and stains makes it an excellent choice for heavily frequented areas such as elevators. Moreover, stainless steel sheets can be customized to meet specific elevator design requirements and are available in a range of finishes, including brushed, mirrored, or patterned, offering a sleek and contemporary appearance. Furthermore, stainless steel is effortless to clean and sanitize, a crucial consideration in public spaces like elevators where hygiene is of utmost importance. In summary, stainless steel sheets present a versatile and pragmatic solution for elevator interiors.

- Q: What is stainless steel plate wire?

- A filament is a unit of length.In mathematics 10 decimillimeter centimillimeter decimillimeter =1 mm, 10 =1

Send your message to us

304 Stainless Steel Sheet with 2B finish

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords