304 Stainless Steel Sheet Widely Use Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

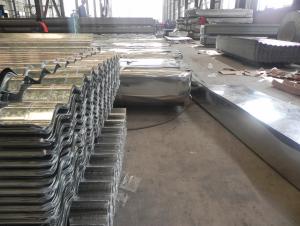

304 stainless steel sheet Widely Use Plate

We are a professional manufacturer of stainless steel sheet. According to ASTM, JIS and AISI,GB, standards, Jaway steel enhances effectiveness and of quality control from selecting the raw materials, cutting, slitting, shearing, surface treatment, packing, exporting of the existing products.

Widely Use Plate 430 Stainless Steel Price with 1.2mm thick 1250mm width

Goods | 304 stainless steel sheet |

Specification | Width: 1000mm-1500mm or as required Length :1000mm-6000mm or as required |

Surface | 2B NO.1 BA Hairline 4K 6K 8K No.3 No.4 |

Type | Sheet/Plate |

Thickness | 0.5 mm-20mm |

Brand | TISCO JISCO LISCO and so on |

Application | stainless steel plate applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields |

Parking | interlayer paper kraft paper wooden packing or as your requirement |

Finishings

| Surface | Definition | Application |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or otherequivalent treatment and lastly by cold rolling to given appropriateluster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

HL | Those finished polishing so as to give continuous polishing streaks byusing abrasive of suitable grain size | Building Construction. |

BA (No.6) | Those processed with bright heat treatment after cold rolling.

| Kitchen utensils, Electric equipment, Building construction. |

Mirror (No.8) | Shinning like a mirror | Building construction |

These are the normal items, for the special requirements,we can also meet.

Surface finish | Characteristics and application |

NO.2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

NO.3 | Polished with abrasive belt of git#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

NO.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria,but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators,door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror,kitchen apparatus,ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Our Advantages

• All products are made of high-quality imported raw materials.

• Our products are certified by ISO9001:2008 authentication quality systems.

• we are nominated as the AAA enterprise by Jiangsu government.

• Quick Response to Your Enquiry.

- Q: How do you attach stainless steel sheets to a wall?

- To attach stainless steel sheets to a wall, you can use a combination of adhesive and mechanical fasteners. First, ensure that the wall is clean and free from any debris or grease. Apply a strong construction adhesive to the back of the stainless steel sheet, spreading it evenly across the surface. Then, press the sheet firmly against the wall and hold it in place for a few minutes to allow the adhesive to bond. Additionally, use mechanical fasteners such as screws or nails to secure the stainless steel sheet to the wall, placing them along the edges and in the center of the sheet for added support and stability.

- Q: Are stainless steel sheets suitable for outdoor signage?

- Stainless steel sheets are indeed appropriate for outdoor signage. This material is widely favored for outdoor uses because of its robustness, ability to resist corrosion, and pleasing appearance. It possesses exceptional resistance to rust and can endure harsh weather conditions, making it particularly suitable for outdoor signage that will be exposed to rain, sunlight, and extreme temperatures. Moreover, stainless steel sheets can be easily personalized and fabricated to craft diverse designs and forms, rendering them a versatile choice for outdoor signage. Furthermore, its sleek and polished finish adds a professional and contemporary touch to any signage. In summary, stainless steel sheets are a dependable and enduring alternative for outdoor signage.

- Q: Are stainless steel sheets suitable for water tanks?

- Yes, stainless steel sheets are suitable for water tanks. Stainless steel is highly resistant to corrosion and rust, making it an ideal material for water storage. It is durable, long-lasting, and can withstand high water pressures. Additionally, stainless steel is hygienic, easy to clean, and does not contaminate the water.

- Q: What is the maximum size available for stainless steel sheets?

- The maximum size available for stainless steel sheets depends on several factors, including the manufacturing capabilities of the supplier and the specific requirements of the customer. Stainless steel sheets are typically available in standard sizes, which can vary depending on the thickness and grade of the stainless steel. In general, stainless steel sheets can be found in sizes ranging from 4 feet by 8 feet (1220mm x 2440mm) to larger sizes such as 5 feet by 10 feet (1524mm x 3048mm). However, it is also possible to find custom sizes or oversized sheets that exceed these dimensions, especially for industrial or specialized applications. It is important to note that larger sizes may come with additional challenges, such as increased weight and handling difficulties. Additionally, the availability of specific sizes may vary among suppliers, so it is recommended to consult with a stainless steel sheet supplier or manufacturer for the exact maximum size options they offer.

- Q: How do you join stainless steel sheets together?

- Different methods can be employed to connect stainless steel sheets, depending on the desired outcome and specific application. Here, we present a few commonly used techniques: 1. Welding: Stainless steel sheets can be welded using various methods like TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), or spot welding. Through welding, a strong and enduring bond is formed between the sheets, ensuring a secure connection. 2. Mechanical Fastening: By utilizing mechanical fasteners such as screws, bolts, or rivets, stainless steel sheets can be effectively joined. This approach is commonly employed when disassembly or reassembly is necessary, as it allows for easy removal and reinstallation. 3. Adhesive Bonding: Specialized adhesives specifically designed for stainless steel can be utilized to connect sheets together. These adhesives create a robust bond while preserving the aesthetics of the stainless steel surface. However, adhesive bonding may not be suitable for applications involving high stress or temperature. 4. Clinching: The clinching method involves applying a special tool to press the stainless steel sheets together, resulting in a mechanical interlock. This technique is frequently used for joining thin sheets and offers a cost-effective and expeditious solution. When selecting the most suitable method, it is crucial to consider the project's specific requirements, including load-bearing capacity, temperature, corrosion resistance, and aesthetics. Seeking guidance from a professional or conducting thorough research can assist in ensuring that the chosen joining technique is appropriate for the intended application.

- Q: Stainless steel drawing plate, polishing plate, mirror panels of the three differences

- Stainless steel wire drawing refers to: stainless steel wire drawing is stainless steel surface like filamentous texture, this is only a stainless steel processing technology. The surface is Matt, and carefully look at the above there is a trace of texture, but can not touch it.

- Q: Can stainless steel sheets be formed into complex shapes?

- Yes, stainless steel sheets can be formed into complex shapes. Stainless steel is known for its excellent formability and versatility, making it one of the most widely used materials in various industries. It can be easily fabricated using techniques such as bending, rolling, stamping, and deep drawing, allowing the formation of complex shapes with precision and accuracy. Moreover, stainless steel has high ductility and can withstand significant deformation without losing its mechanical properties or structural integrity. As a result, it is often preferred for applications that require intricate and customized designs, such as architectural structures, automotive parts, kitchen appliances, and medical equipment.

- Q: Are stainless steel sheets suitable for food preparation surfaces?

- Yes, stainless steel sheets are highly suitable for food preparation surfaces. Stainless steel is a popular choice for kitchen countertops, cutting boards, and other food preparation surfaces due to its numerous beneficial properties. Firstly, stainless steel is non-porous, which means it does not absorb or retain odors, flavors, or bacteria. This makes it extremely hygienic and easy to clean, reducing the risk of cross-contamination. Additionally, stainless steel is resistant to corrosion, staining, and heat, making it durable and long-lasting. Its smooth surface also makes it ideal for rolling out dough or chopping ingredients. Furthermore, stainless steel is a non-reactive material, so it does not interact with acidic or alkaline foods, ensuring the taste and quality of the prepared food is not compromised. Overall, stainless steel sheets are an excellent choice for food preparation surfaces due to their cleanliness, durability, and food safety qualities.

- Q: Can stainless steel sheets be used for architectural canopies?

- Architectural canopies can indeed make use of stainless steel sheets. This versatile material offers numerous advantages in architectural applications, including canopies. To begin with, stainless steel possesses great durability and resistance to corrosion, making it ideal for outdoor installations. This ensures that the canopy will endure harsh weather conditions and maintain its appearance over time. Furthermore, stainless steel boasts a sleek and contemporary aesthetic which can enhance the overall design of the canopy. It can be polished to a mirror-like finish or brushed to create a distinctive texture, giving architects a range of options to achieve their desired look. In addition, stainless steel sheets are available in various thicknesses, allowing for customization based on the specific requirements of the canopy. This flexibility guarantees that the material can support the weight of the structure and any additional elements, such as lighting or signage. Moreover, stainless steel is an environmentally-friendly choice for architectural canopies as it is fully recyclable. This aligns with the increasing demand for sustainable construction materials and practices. To summarize, stainless steel sheets are a popular and suitable choice for architectural canopies due to their durability, aesthetic appeal, flexibility, and sustainability.

- Q: How do you prevent pitting corrosion on stainless steel sheets?

- To prevent pitting corrosion on stainless steel sheets, it is important to maintain a clean and dry surface, avoid exposure to corrosive environments or chemicals, and promptly clean off any contaminants or deposits. Additionally, applying a protective coating or passivation treatment can help enhance the corrosion resistance of the stainless steel sheets. Regular inspections and maintenance are also crucial to detect and address any signs of pitting corrosion early on.

Send your message to us

304 Stainless Steel Sheet Widely Use Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords