304 4x8 Stainless Steel Sheet Metal Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 25000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

304 4x8 Stainless Steel Sheet Metal Price

1.Product Description

1. Specifications about stainless steel sheet

Commodity430 304 304L 316L 201 316 4x8 sheet metal prices stainless steel

Grade201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L

BrandTISCO ,BAOSTEEL,POSCO,JISCO,LISCO

CertificationSGS,BV,IQI,TUV,ISO,etc

Thickness0.2mm-150mm

Width1000,1219,1250,1500mm, or as your requirements

Length2000,2438,2500,3000,6000mm, or as your requirements

SurfaceNo.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film.

StandardASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc

Delivery time5-7 days after confirming the order

MOQ1 Ton

AdvantagesShowing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste.

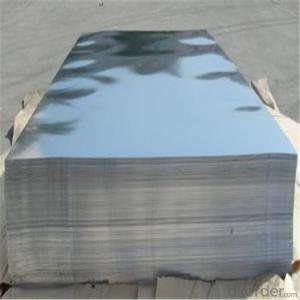

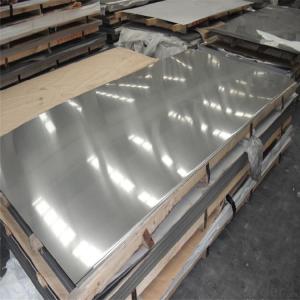

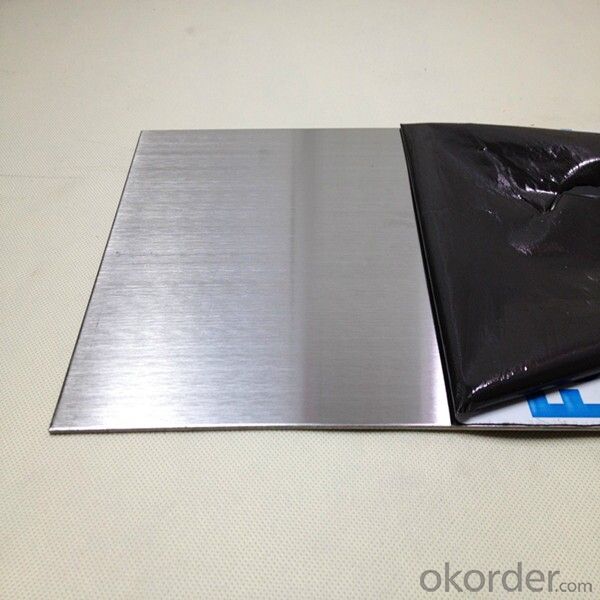

2.Products photos

3.FAQ

1.Small quantity, short time delivery

If we have stocks, the delivery time is less than 7 days,If the quantity is more than 500Tons,the delivery time is abou 30 days after confirming the order.

2.Choose the appropriate metals stainless steel for your needs.

We carefully balance quality, delivery time and price,procure various grades metals from all over the world.

3.Lower total cost

We taking your processing into account,offer you reduce a total cost by using our product.

We assure you:

Small MOQ + Cheap Price + Fantastic Quality + Fast Delivery

- Q: Can stainless steel sheets be used for brewery tanks?

- Yes, stainless steel sheets are commonly used for brewery tanks. Stainless steel is a preferred material in the brewing industry due to its corrosion resistance, durability, and ease of cleaning. It is an ideal choice for tanks that require high sanitary standards and frequently come in contact with acidic or caustic substances.

- Q: How do I prevent crevice corrosion on stainless steel sheets?

- To prevent crevice corrosion on stainless steel sheets, it is important to keep them clean and free from contaminants. Regularly cleaning the sheets with a mild detergent and water, followed by thorough drying, can help remove any corrosive agents. Additionally, ensuring proper ventilation and avoiding prolonged exposure to high humidity or stagnant conditions can minimize the risk of crevice corrosion. Applying a protective coating or using corrosion inhibitors specifically designed for stainless steel can provide an extra layer of protection against crevice corrosion.

- Q: How do you prevent intergranular corrosion on stainless steel sheets?

- Intergranular corrosion is a type of corrosion that occurs along the grain boundaries of stainless steel, leading to structural damage and reduced strength. To prevent intergranular corrosion on stainless steel sheets, several measures can be taken: 1. Material Selection: Choosing the right grade of stainless steel is crucial in preventing intergranular corrosion. Grades with low carbon content, such as 304L or 316L, are less prone to this type of corrosion due to their reduced susceptibility to sensitization. 2. Heat Treatment: Stainless steel sheets can be heat treated to remove carbide precipitation, a common cause of intergranular corrosion. The process, known as solution annealing or sensitization heat treatment, involves heating the material to a specific temperature range and then rapidly cooling it. This treatment ensures the formation of a consistent and corrosion-resistant microstructure. 3. Passivation: Passivation is a chemical process that removes contaminants and forms a protective oxide layer on the surface of stainless steel sheets. This layer acts as a barrier against corrosion and prevents intergranular attack. Passivation is typically done using nitric acid or citric acid solutions. 4. Welding Techniques: When welding stainless steel sheets, it is important to use proper welding techniques to minimize the risk of intergranular corrosion. This includes using low heat input, avoiding excessive heat build-up, and employing filler materials with low carbon content to prevent sensitization. 5. Avoiding Contamination: Stainless steel sheets should be protected from contamination by other metals, especially those with higher galvanic potentials. Contact with carbon steel, for example, can result in galvanic corrosion and promote intergranular attack. Therefore, it is essential to separate stainless steel sheets from other metals in storage and during fabrication. 6. Regular Cleaning and Maintenance: Regular cleaning and maintenance of stainless steel sheets are essential to prevent the accumulation of corrosive substances or contaminants on the surface. Proper cleaning methods and non-abrasive cleaners should be used to avoid scratching the stainless steel, which can create sites for corrosion initiation. By implementing these preventive measures, intergranular corrosion can be significantly minimized, ensuring the longevity and performance of stainless steel sheets.

- Q: How do stainless steel sheets compare to other types of sheet metals?

- Stainless steel sheets offer several advantages over other types of sheet metals. They are highly resistant to corrosion, making them ideal for applications where exposure to moisture or chemicals is common. Stainless steel sheets are also durable and can withstand high temperatures, making them suitable for various industrial and construction purposes. Additionally, they have an attractive appearance and are easy to clean, making them a popular choice in architectural and decorative applications.

- Q: How do you remove fingerprints from brushed stainless steel sheets?

- To remove fingerprints from brushed stainless steel sheets, you can use a microfiber cloth or a soft cloth dampened with warm soapy water to gently wipe away the fingerprints. Avoid using abrasive cleansers or scrub brushes as they can damage the brushed finish. Dry the surface thoroughly with a clean cloth to prevent water spots.

- Q: Are stainless steel sheets suitable for marine propellers?

- Marine propellers can indeed be made from stainless steel sheets. This material is highly favored for its exceptional ability to resist corrosion, a crucial quality when the propeller is regularly exposed to saltwater in a marine setting. Furthermore, stainless steel sheets possess remarkable strength and durability, allowing them to withstand the harsh conditions of the marine environment, including impacts and vibrations. Additionally, the low magnetic permeability of stainless steel helps minimize the formation of biofouling on the propeller, thereby enhancing its efficiency and performance. All in all, stainless steel sheets are extensively utilized and considered a suitable choice for marine propellers.

- Q: What is the water absorption rate of stainless steel sheets?

- The water absorption rate of stainless steel sheets is extremely low, as stainless steel is a non-porous material that does not readily absorb water.

- Q: Can stainless steel sheets be used in food processing applications?

- Yes, stainless steel sheets can be used in food processing applications. Stainless steel is a commonly used material in the food industry due to its corrosion resistance, durability, and hygienic properties. It is easy to clean and maintain, making it suitable for food processing equipment such as countertops, work surfaces, and storage containers.

- Q: Can stainless steel sheets be used for chemical processing equipment?

- Yes, stainless steel sheets can be used for chemical processing equipment. Stainless steel is highly resistant to corrosion, making it an ideal material for handling and processing various chemicals. It has excellent strength and can withstand high temperatures and pressures, making it suitable for a wide range of chemical processes. Additionally, stainless steel is easy to clean and maintain, which is crucial for maintaining the purity of chemicals being processed. Overall, stainless steel sheets are a popular choice for chemical processing equipment due to their durability, resistance to corrosion, and ability to meet the stringent requirements of chemical processing environments.

- Q: Can stainless steel sheets be used for electrical enclosures?

- Stainless steel sheets are indeed suitable for electrical enclosures. With their highly durable and corrosion-resistant properties, they offer excellent safeguarding for electrical components. Their strength allows them to endure harsh environmental conditions, making them applicable for both indoor and outdoor uses. Furthermore, stainless steel exhibits good conductivity and efficient heat dissipation, ensuring optimal temperature control within the enclosure. These remarkable qualities make stainless steel sheets a dependable option for electrical enclosures, guaranteeing enduring performance and protection for the enclosed equipment.

Send your message to us

304 4x8 Stainless Steel Sheet Metal Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 25000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords