300 Series Grade and JIS,AISI Standard stainless Steel per ton ISO certificate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: 201,304,310S,316L,410,430,403

Thickness: 0.4-5mm

- Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Special Use: High-strength Steel Plate

Width: 1500-2500mm

quality: high quality

price: low price

Packaging & Delivery

| Packaging Details: | Iron sheet packing or as clients' requirement |

|---|---|

| Delivery Detail: | within 10-30 working days |

Specifications

material quality:201,304,310S,316L,410,430,403

specification:0.4-5.0*1000/1219*1500

high quanlity and Competitive price

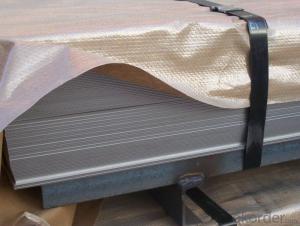

Stainless Steel Plate/Sheet/Coil

201,202,304,316,304L,316L,309S,310S,321,410,420,430,403

Introduction

stainless steel is one of Austenitic stainless steel. As a versatile steel, it has good corrosion resistance, heat resistance, low temperature strength and mechanical properties. Meanwhile, it is quite good in pressing, bending and other thermal processing.

Standard

The chemical and mechanical composition of the material is in accordance with GB,JIS,ASTM,and EN.

200,300,400series,201,202,301,304,304L,309S,310S,316,316L,410,430,etc.

Specification:

Our coils are directly ordered from mills.300 series stainless steel(304,304L,316L,321),duplex(2205),heat resistant steel(309s,310s)are the main product.Thickness from 0.2mm to 20mm,width is from 300mm to 2000mm,weight is from 2 tons to 26 tons.

Technology

cold draw, hot rolled, cutting, split, polished, protect coating as customer requirement

Packing

Iron sheet packing or as clients' requirement

Quality

MTC,ISO ,BV ,SGS CERTIFICATE

Application:

Machinemade industry, chemical industry, shipping industry architecture, food industry,household products,and so on.

chemical properties--stainless steel coil

| Typical chemical composition | ||||

| % | 304 | 304L | 310s | 321 |

| C | 0-0.07 | 0-0.03 | 0.8 | 0.08 |

| Mn | 0-2.0 | 0-2.0 | 2.00 | 2.00 |

| Si | 0-1 | 0-1 | 1.00 | 1.00 |

| P | 0-0.05 | 0-0.05 | 0.035 | 0.035 |

| S | 0-0.02 | 0-0.02 | 0.030 | 0.03 |

| Cr | 17.5-19.5 | 17.5-19.5 | 24.0-26.0 | 17.0-19.0 |

| Ni | 8-10.5 | 8-10.5 | 19.0-22.0 | 9.0-12.0 |

| Mo | ||||

| TI | 5×C% | |||

- Q: Can steel sheets be used for solar panel structures?

- Yes, steel sheets can be used for solar panel structures. Steel is a popular choice for constructing solar panel structures due to its strength, durability, and versatility. Steel sheets can be easily fabricated and shaped to meet specific design requirements, making them suitable for various types of solar panel installations. Additionally, steel has excellent load-bearing capabilities, which is crucial for supporting the weight of solar panels. It is also resistant to corrosion and can withstand harsh weather conditions, making it a reliable material for long-term use in outdoor settings. Overall, the use of steel sheets for solar panel structures is a practical and cost-effective solution.

- Q: Are steel sheets resistant to radiation or electromagnetic interference?

- Steel sheets are not inherently resistant to radiation or electromagnetic interference. However, their thickness can provide some level of shielding against certain types of radiation, such as gamma radiation. For protection against electromagnetic interference, additional layers or coatings specifically designed to block or absorb electromagnetic waves may be required.

- Q: What does "steel plate 10t" mean in the specification column of engineering material?

- The width of the sheet is 500~1500 mm; the thickness is 600~3000 mm. According to the type of steel sheet, ordinary steel, stainless steel, alloy steel, spring steel, stainless steel, tool steel, heat-resistant steel, bearing steel, silicon steel and industrial pure iron sheet; according to professional use, with drums board, enamel board, bulletproof plate; surface coating and plating, plating with zinc thin plate, tin plate, plating lead sheet, plastic composite plate.

- Q: Are steel sheets easy to install?

- Yes, steel sheets are generally easy to install as they are lightweight and come in various sizes, allowing for easy handling and maneuverability during installation. Additionally, steel sheets often have pre-drilled holes or slots, facilitating the installation process.

- Q: What is the average cost of installing steel sheets?

- The cost of installing steel sheets can differ depending on several factors, including project size, steel sheet type and quality, location, and labor expenses. On average, the installation cost varies between $7 and $15 per square foot. Nevertheless, it is crucial to acknowledge that this is merely a general approximation, and actual expenses might differ significantly. It is advisable to obtain quotations from multiple contractors or steel suppliers to acquire a more precise estimate tailored to a specific project.

- Q: What is the average thickness of galvanized steel sheets?

- The average thickness of galvanized steel sheets can vary depending on the specific application and industry standards. However, commonly available galvanized steel sheets typically range in thickness from around 0.4 millimeters to 3.175 millimeters. It is important to note that thicker galvanized steel sheets are often used for more heavy-duty applications, such as construction and industrial purposes, while thinner sheets may be suitable for lighter applications like automotive or household appliances. Additionally, it is advisable to consult the relevant industry standards or manufacturers' specifications for precise thickness requirements for specific applications.

- Q: Can steel sheets be used for manufacturing industrial shelving?

- Indeed, industrial shelving can be manufactured using steel sheets. Renowned for their robustness and endurance, steel sheets prove to be a perfect choice for demanding tasks like heavy-duty industrial shelving. Able to endure substantial weights, they supply steadfastness and reinforcement to these storage units. Moreover, steel sheets can be effortlessly fashioned and tailored to meet precise dimensions and specifications. Their exceptional resistance to corrosion is of utmost significance in industrial settings where encounters with dampness, chemicals, and other harsh circumstances are frequent. All in all, steel sheets present a dependable and enduring option for the production of industrial shelving.

- Q: Can steel sheets be formed into corrugated panels?

- Yes, steel sheets can be formed into corrugated panels.

- Q: Can steel sheets be used for manufacturing kitchen utensils?

- Yes, steel sheets can be used for manufacturing kitchen utensils. Steel is a common material used in the production of utensils due to its durability, heat resistance, and hygienic properties. Steel sheets can be easily shaped and molded into various utensil designs, making them suitable for manufacturing kitchen tools such as pots, pans, cutlery, and other cookware.

- Q: Are steel sheets suitable for marine environments?

- Yes, steel sheets are suitable for marine environments due to their high strength and corrosion resistance properties. They can withstand harsh conditions such as saltwater exposure and are commonly used in the construction of ships, offshore platforms, and other marine structures.

Send your message to us

300 Series Grade and JIS,AISI Standard stainless Steel per ton ISO certificate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords