Gear Steel SAE 1020 Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Gear Steel SAE 1020 Carbon Steel Round Bar

Product Information:

1. Standard GB:20, AISI: 1020, JIS: S20C

2. Specification

Dia: 8mm-480mm or according to your requirements

Length: 1m-12mm or according to your requirements

3. Delivery Condition

Hot rolled, forged, QT heat treatment and normalizing

4. Characteristics:S20C/ 1020/ 20

1) The strength and hardness of S20C/ 1020/ 20 is higher than that of S15C/ 1015/ 15.

2) Good plasticity and weldability.

3) Good toughness after hot rolling and normalization.

5. Application: High-quality carbon structural steel/S20C/ 1020/ 20

S20C structural carbon steel bar /1020 /20 can be used to be manufactured medium or small carburization or nitrocarburizing parts and press forging parts, such as lever shaft, selector fork of speed changing box, gear, heavy mechanical lever and shackle, etc.

Product Overviews:

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 | GB/SAE/JIS/DIN |

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

| Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

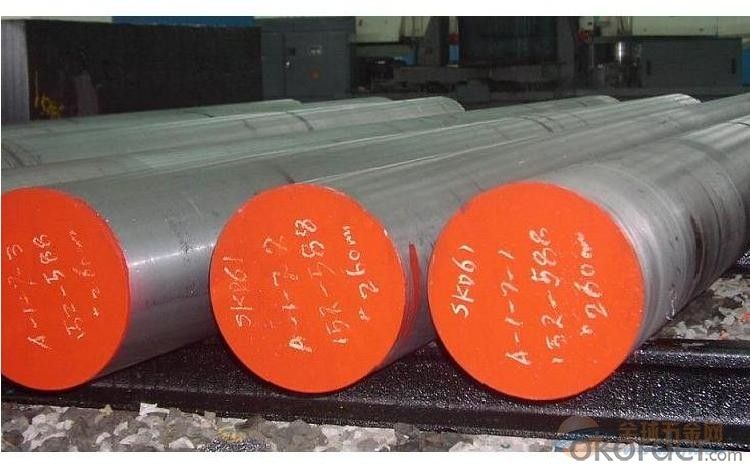

Product Show:

Our Advantages:

· Industry experience over 20 years.

· Shipment of goods -More than 70 countries worldwide.

· The most convenient transport and prompt delivery.

· Competitive price with best service.

· High technical production line with top quality products.

· High reputation based on best quality products.

With our experienced, enthusiastic and dynamic staffs, we assure to bring you the products with best quality, reasonable prices and good after-sales services under the motto: Friends First, Business After.

Communication, Experience, Expertise and Best efforts are our Promises to you.

- Q: What are the common challenges in machining titanium alloys?

- Successful and efficient results in machining titanium alloys require addressing several common challenges. One primary challenge is the inherent strength and hardness of the material. Titanium alloys are renowned for their excellent strength-to-weight ratio, making them ideal for various applications. However, this same strength makes them difficult to machine. The high strength of titanium alloys increases the cutting forces needed during machining, resulting in faster tool wear and reduced tool life. This necessitates the use of robust cutting tools made from carbide or ceramic, capable of withstanding demanding conditions and maintaining cutting performance. Another challenge in machining titanium alloys is their poor thermal conductivity. This characteristic leads to rapid heat buildup during cutting, causing localized high temperatures. These high temperatures can cause thermal damage to both the cutting tool and the workpiece, reducing dimensional accuracy and surface finish. To overcome this challenge, implementing effective cooling and lubrication techniques, such as using coolant or high-pressure air, is crucial to dissipate heat and prevent overheating. Furthermore, machining titanium alloys often results in the generation of built-up edge (BUE). BUE refers to the accumulation of workpiece material on the cutting tool, leading to poor chip evacuation, increased cutting forces, and surface finish issues. To mitigate BUE formation, it is recommended to use appropriate cutting speeds and feed rates, as well as cutting fluids that aid in chip evacuation and prevent material adhesion on the tool. Additionally, titanium alloys react strongly with oxygen, causing the formation of a stubborn oxide layer on the surface during machining. This oxide layer can cause tool chipping and premature wear. To combat this, it is necessary to employ suitable cutting speeds and feeds that efficiently remove material while minimizing prolonged exposure to the reactive nature of titanium alloys. Lastly, the low thermal expansion coefficient of titanium alloys can result in workpiece distortion and dimensional inaccuracies. To address this challenge, it is important to ensure proper fixturing and clamping techniques that minimize workpiece movement during machining. In conclusion, machining titanium alloys presents challenges such as high cutting forces, poor thermal conductivity, built-up edge formation, reactive oxide layer, and workpiece distortion. These challenges can be overcome by using appropriate cutting tools, effective cooling and lubrication techniques, proper cutting parameters, and careful workpiece handling.

- Q: Can special steel be used in the sporting goods manufacturing industry?

- Yes, special steel can be used in the sporting goods manufacturing industry. Special steel alloys offer superior strength, durability, and corrosion resistance, which are crucial qualities for manufacturing various sporting goods such as golf clubs, bike frames, tennis rackets, and baseball bats. These alloys can be tailored to meet specific requirements, ensuring high performance and longevity in sports equipment.

- Q: What are the common challenges in welding titanium alloys?

- Welding titanium alloys poses several common challenges, mainly due to the unique properties of titanium. First, titanium has a high melting point, around 1668°C (3034°F), which requires specialized equipment and techniques to achieve optimal welding conditions. This high melting point also increases the risk of overheating and subsequent distortion or warping of the welded parts. Another challenge is the high reactivity of titanium with oxygen, nitrogen, and hydrogen. During the welding process, these gases can easily contaminate the weld pool, leading to the formation of brittle and porous welds. Therefore, stringent measures such as using inert shielding gases like argon or helium, maintaining a high level of cleanliness, and employing proper welding techniques like gas tungsten arc welding (GTAW) are necessary to minimize contamination and achieve sound welds. Titanium also has a strong affinity for carbon, which can result in the formation of brittle intermetallic compounds during welding. To prevent this, it is crucial to use low-carbon filler metals and ensure proper heat input to avoid carbon diffusion into the weld zone. Furthermore, titanium alloys have a low thermal conductivity, which means that heat generated during welding tends to concentrate in a small area, leading to localized overheating and potential damage. Therefore, controlling heat input and employing appropriate welding techniques to distribute heat evenly are crucial to avoid overheating and maintain the integrity of the welded joint. Lastly, titanium alloys exhibit a high thermal expansion coefficient, causing significant thermal expansion and contraction during the welding process. This can result in distortion and residual stresses in the welded parts. To mitigate these issues, preheating and post-weld heat treatment may be necessary to minimize distortion and relieve residual stresses. In summary, the common challenges in welding titanium alloys include high melting point, reactivity with gases, potential contamination, formation of intermetallic compounds, low thermal conductivity, and significant thermal expansion. By understanding these challenges and implementing appropriate welding techniques, it is possible to overcome these difficulties and achieve high-quality welds in titanium alloys.

- Q: Can special steel be used in automotive engine components?

- Yes, special steel can be used in automotive engine components. Special steel, also known as alloy steel, is specifically designed to have enhanced properties such as increased strength, toughness, and heat resistance. These properties make it ideal for use in critical engine components that are subjected to high temperatures, stress, and wear. In automotive engines, special steel can be used in various components such as crankshafts, camshafts, connecting rods, valves, and piston rings. These components are subjected to extreme conditions, including high temperatures, pressure, and rotational forces. Special steel provides the required strength and durability to withstand these conditions, ensuring reliable engine performance and longevity. The use of special steel in automotive engine components offers several advantages. Firstly, it increases the strength and load-carrying capacity of the components, allowing them to handle higher power and torque outputs. Secondly, special steel improves the fatigue resistance and durability of the components, reducing the risk of failure and extending their service life. Lastly, special steel can withstand the high temperatures and thermal cycling experienced in the engine, preventing deformation and maintaining dimensional stability. Overall, the use of special steel in automotive engine components is crucial for achieving optimal performance, reliability, and longevity. It ensures that the engine can withstand the demanding conditions it operates under, providing a smoother and more efficient driving experience.

- Q: What are the different magnetic grades of special steel?

- The different magnetic grades of special steel include ferritic, martensitic, austenitic, and duplex stainless steels.

- Q: Does special steel have any magnetic properties?

- Yes, special steel can have magnetic properties. The magnetic properties of special steel depend on its composition and processing. Some types of special steel are specifically designed to be magnetic, while others may have low magnetic permeability.

- Q: What are the advantages of using special steel over other materials?

- There are several advantages of using special steel over other materials. Firstly, special steel has higher strength and toughness, making it more durable and resistant to wear and tear. Secondly, it offers excellent corrosion resistance, preventing rust and extending the lifespan of the product. Additionally, special steel can withstand extreme temperatures, making it suitable for applications in various industries. Moreover, its versatility allows for easy customization and shaping, meeting specific design requirements. Lastly, special steel is known for its high recyclability, making it an environmentally friendly choice.

- Q: How does special steel perform in hot forging processes?

- Special steel performs exceptionally well in hot forging processes due to its high temperature resistance and excellent strength retention at elevated temperatures. It can withstand the extreme heat generated during forging, preventing deformation or cracking. Moreover, special steel exhibits superior wear resistance, facilitating the production of intricate and complex shapes without compromising its durability. Its exceptional performance in hot forging processes makes it a preferred choice for manufacturing industries.

- Q: What are the quality control measures for special steel?

- Quality control measures for special steel involve several key steps and processes to ensure that the final product meets the required standards and specifications. These measures typically include: 1. Raw Material Inspection: Thoroughly checking the quality and composition of the raw materials used in the production of special steel, such as ensuring the correct chemical composition and metallurgical properties. 2. Process Control: Implementing strict controls and monitoring throughout the manufacturing process to ensure consistent quality, such as maintaining precise temperature control during heating and cooling processes, controlling the rolling or forging parameters, and ensuring proper heat treatment. 3. Testing and Sampling: Conducting various tests and sampling techniques to assess the quality of the special steel, including mechanical tests (such as tensile strength, hardness), non-destructive testing (like ultrasonic or magnetic particle inspection), and chemical analysis. 4. Dimensional and Surface Inspection: Verifying that the dimensions and surface finish of the special steel conform to the required specifications, such as measuring length, diameter, straightness, and checking for any defects or irregularities. 5. Final Inspection and Certification: Performing a final inspection to ensure that the special steel meets all quality standards and customer requirements. This may involve visual examination, additional testing, and issuing necessary certifications or quality assurance documents. By implementing these quality control measures, manufacturers can ensure the reliability, durability, and consistent performance of special steel, making it suitable for various critical applications in industries like automotive, aerospace, energy, and construction.

- Q: How does special steel contribute to reducing product defects?

- Special steel contributes to reducing product defects by offering superior strength, durability, and corrosion resistance compared to regular steel. This ensures that the components made from special steel are less prone to breakage, wear and tear, or damage during manufacturing, transportation, or usage. Special steel's high-quality characteristics provide a more reliable and consistent performance, resulting in fewer product defects and improved overall product quality.

Send your message to us

Gear Steel SAE 1020 Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords