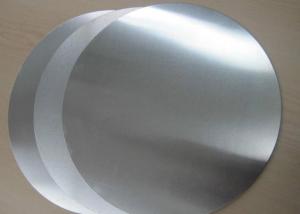

2023 New production High Quality 3003 Alloy Aluminium Circle and Aluminum Disc

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1.Specification & Description

2.Application :

For Aluminium cookware,pot,pan,stock pots,frypan,reflector of the light

3.Packing Pictures

- Q: Are aluminum sheets suitable for welding?

- Yes, aluminum sheets are suitable for welding. Aluminum is a widely used material in various industries due to its lightweight, corrosion resistance, and excellent thermal conductivity. However, welding aluminum can be more challenging compared to other metals due to its high thermal conductivity and the formation of an oxide layer on its surface. Nevertheless, with the appropriate welding techniques and equipment, aluminum sheets can be successfully welded. Specialized welding processes such as Tungsten Inert Gas (TIG) welding or Metal Inert Gas (MIG) welding are commonly used for aluminum welding. These processes allow for precise control of heat input and the use of suitable shielding gases to protect the weld pool from oxidation. Additionally, proper surface preparation, cleaning, and the use of specialized aluminum welding wires or rods are essential for achieving strong and reliable welds. Overall, while welding aluminum may require specific techniques and equipment, it is definitely feasible and commonly practiced in various industries.

- Q: Can you make tank armor using Aluminium, Polymers, Styrofoam, Explosive Reactive Armor to stop NATO DP rounds and/or HEAT rounds maybe RPG-7?

- Aluminium has a strength up to 800 N/mm2 (for its best Al-based alloys) while steels can go much higher... about 1400 N/mm2 if I recall well. The problem with aluminium is that is prompt to fatigue break which is not good with something vibrating like a rolling tank armor. Polymers are not strong enough unless you use composite materials, for ex. fibre glass or even better - carbon fibre reinforced. The problem is still that unlike steel, the strength is exceptionally high... in one direction - so pray for the impact to be mostly from this direction.

- Q: Can aluminum sheets be used for decorative wall panels?

- Yes, aluminum sheets can be used for decorative wall panels. Aluminum is a versatile material that offers a wide range of design options for wall panels. It is lightweight, durable, and resistant to corrosion, making it suitable for both interior and exterior applications. Aluminum sheets can be easily cut, formed, and fabricated into various shapes, patterns, and finishes, allowing for endless design possibilities. Additionally, aluminum can be powder-coated or anodized to enhance its appearance and provide additional protection against wear and tear. Whether it's for residential or commercial spaces, aluminum sheets can add a modern and stylish touch to any wall, making them a popular choice for decorative wall panels.

- Q: This question asks if aluminum sheets can be recycled repeatedly without losing their quality.

- <p>Yes, aluminum sheets can be recycled multiple times without losing their quality. Aluminum is a highly recyclable material, and the recycling process does not degrade the material's properties. In fact, recycled aluminum requires significantly less energy to produce compared to mining and refining new aluminum from bauxite ore. This makes aluminum recycling an environmentally friendly and cost-effective process, contributing to sustainability and reducing the demand for raw materials.</p>

- Q: This question asks for a comparison of various types of aluminum sheet materials, highlighting their unique characteristics and differences.

- <p>Aluminum sheet materials vary based on alloy composition, thickness, and surface treatment. Common types include 1000 series (99% pure aluminum), 3000 series (alloys like 3003 and 3004), 5000 series (magnesium alloys), and 6000 series (magnesium-silicon alloys). Each series has distinct properties: 1000 series is soft and ductile, 3000 series offers moderate strength and good formability, 5000 series has high strength and corrosion resistance, and 6000 series is known for its strength and excellent weldability. Thickness and temper (hardness) also affect performance, with thinner sheets being more flexible and harder tempers offering greater strength. Surface treatments like anodizing or painting can enhance appearance and corrosion resistance.</p>

- Q: Are aluminum sheets resistant to staining?

- Yes, aluminum sheets are generally resistant to staining due to their natural ability to form a protective oxide layer on the surface, which prevents corrosion and staining.

- Q: Can aluminum sheets be used for missile components?

- Indeed, missile components can indeed be made from aluminum sheets. Aluminum, an adaptable and light substance, boasts remarkable strength-to-weight ratio properties. These attributes render it a fitting option for a range of aerospace uses, including missile components. Aluminum sheets present benefits like resistance to corrosion, excellent thermal conductivity, and simplicity in fabrication. Moreover, aluminum exhibits the ability to endure extreme temperatures, making it a suitable choice for missile components that might encounter intense heat during flight. Nevertheless, it is crucial to take into account the specific requirements of the missile system and seek guidance from authorities in the field to ensure that aluminum sheets are suitable for the intended purpose.

- Q: This question asks for methods to preserve an aluminum window and prevent rust or corrosion.

- <p>To maintain an aluminum window and prevent rusting or corrosion, follow these steps: Regularly clean the window with a mild detergent and water to remove dirt and grime. Avoid using abrasive cleaners or tools that could scratch the surface. Apply a protective coating or sealant designed for aluminum to shield it from moisture and environmental factors. Ensure proper drainage around the window to prevent water accumulation. Regularly inspect the window for signs of damage or corrosion and address any issues promptly. By following these maintenance practices, you can prolong the life of your aluminum window and keep it in good condition.</p>

- Q: Explain how the use of aluminum sheets can impact the visual appeal of a building.

- <p>Aluminum sheets can significantly enhance the aesthetic appearance of a building due to their versatility, durability, and modern look. They offer a sleek and contemporary design, available in various colors, finishes, and textures, allowing architects to create unique and visually striking facades. Their resistance to corrosion and weathering ensures that the building maintains its appearance over time, while their lightweight nature can contribute to innovative architectural designs. Additionally, aluminum sheets can be easily shaped and cut, enabling complex and intricate designs that add to the visual appeal of the structure.</p>

- Q: Are aluminum sheets suitable for decorative screens?

- Yes, aluminum sheets are suitable for decorative screens. They are lightweight, durable, and can be easily customized into various shapes and designs. Additionally, aluminum's corrosion resistance makes it suitable for both indoor and outdoor applications, making it a popular choice for decorative screens.

Send your message to us

2023 New production High Quality 3003 Alloy Aluminium Circle and Aluminum Disc

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords