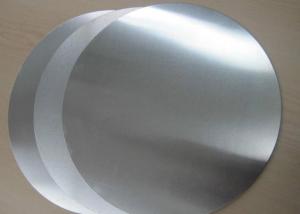

High Quality Aluminum 3003/8011 Mill Price Aluminum Circle

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Aluminium Circle for Cooking Utensils

1. Alloy: 3003, 8011

2. Temper: O,H12,H14,H16,H18,H19,H22,H24,H26

3. Hardness: 26 ~ 29

4. Elongation Percentage: 36% ~ 45%

5. Surface Treatment: Coated or Non-Coated

6. Thickness: 0.50mm ~ 6mm

7. Diameter: 100mm - 1520mm

8. Type: Discs, Circle

Product Applications:

Deep drawing quality,Less Scrap.

Suitable for making cookware and following products:

+Stock pots +Fry pans +Tea kettles

+Pressure cookers +Pizza pans + Rice cookers

+Restaurant cookware +Coffee urns + Electric skillets

+Bakeware, Bread Makers + Stainless cookware bottom plates.

Packing And Loading:

Standard Export Package And Customized Packing Ways Are Welcomed

- Q: Is it possible to use aluminum as a substance that accelerates chemical reactions?

- <p>Aluminum is not typically used as a catalyst in chemical reactions. Catalysts are substances that increase the rate of a chemical reaction without being consumed in the process. Aluminum, being a metal with a +3 oxidation state, does not readily participate in reactions where it could act as a catalyst. Instead, it is more commonly used in its elemental form for structural purposes or as a reducing agent in certain chemical processes. However, aluminum compounds, such as alumina (Al2O3), can be used as catalysts or catalyst supports in specific industrial applications.</p>

- Q: This question asks about the chemical reactions of aluminum with acids and alkalis under various conditions.

- <p>Aluminum reacts differently with acids and alkalis depending on the specific environment. In the presence of acids, such as hydrochloric or sulfuric acid, aluminum undergoes a redox reaction where it loses electrons and forms aluminum ions (Al^3+). The reaction can be represented as: 2Al + 6HCl 鈫?2AlCl鈧?+ 3H鈧? With alkalis, aluminum reacts to form aluminate ions and hydrogen gas. This reaction is represented as: 2Al + 2NaOH + 6H鈧侽 鈫?2NaAl(OH)鈧?+ 3H鈧? The rate of these reactions can be influenced by factors such as temperature, concentration, and the presence of catalysts.</p>

- Q: Can reusing old aluminum foil be utilized for cleaning tasks in kitchen or bathroom areas?

- <p>Yes, old aluminum foil can be used for cleaning purposes in a kitchen or bathroom. It's particularly effective for scrubbing pots and pans, removing burnt-on food, and cleaning glass and tiles. The shiny side of the foil can be used to remove scuff marks from floors and the dull side can be used to scrub away stubborn stains. However, it's important to avoid using foil that has been in contact with acidic or corrosive substances, as it may have become damaged or weakened, and could potentially scratch surfaces. Always test on a small, inconspicuous area first to ensure it doesn't damage the surface you're cleaning.</p>

- Q: Can recycled aluminum be utilized in the production of solar panels and other renewable energy technologies?

- <p>Yes, recycled aluminum can be used to make solar panels and other renewable energy sources. Aluminum is a key component in solar panel frames and mounting structures due to its lightweight, high strength, and corrosion resistance. Recycling aluminum saves energy and resources compared to mining and refining new aluminum. Additionally, recycled aluminum can be used in wind turbines, hydroelectric generators, and other renewable energy technologies where its properties are beneficial. The use of recycled materials in renewable energy production contributes to a more sustainable and circular economy.</p>

- Q: Angell doors and windows as a door brand, compared to other aluminum alloy doors and windows what are the advantages?

- Patterns, products, services have advantages, you can go to their official website to see.

- Q: Describe the chemical reaction that occurs when aluminum reacts with an acid.

- <p>When aluminum reacts with an acid, it undergoes a single displacement reaction. The general reaction can be represented as: 2Al + 6HCl 鈫?2AlCl鈧?+ 3H鈧? In this reaction, aluminum (Al) displaces hydrogen (H) from the hydrochloric acid (HCl), forming aluminum chloride (AlCl鈧? and hydrogen gas (H鈧?. The aluminum atoms lose three electrons each to form Al鲁鈦?ions, while the hydrogen ions (H鈦? from the acid gain electrons to form hydrogen gas. This reaction is exothermic, releasing heat and often producing bubbles of hydrogen gas.</p>

- Q: This question seeks to understand the safety standards that aluminum products must adhere to, ensuring they are safe for use and do not pose health or environmental risks.

- <p>Safety standards for aluminum products vary by region and application but generally focus on ensuring the products are safe for their intended use and do not pose health or environmental risks. Standards often cover material composition, manufacturing processes, and finished product testing. For example, the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) provide standards for aluminum alloys and their applications. Additionally, the Food and Drug Administration (FDA) has specific guidelines for aluminum used in food contact materials to prevent contamination. Compliance with these standards is crucial for manufacturers to maintain product safety and consumer trust.</p>

- Q: This question asks about the potential health hazards associated with exposure to aluminum in a work environment.

- <p>Working with aluminum can pose certain health risks, primarily due to inhalation of aluminum dust or fumes. Chronic exposure may lead to respiratory issues such as aluminum lung disease, characterized by shortness of breath and cough. Additionally, aluminum has been linked to neurological disorders, including cognitive dysfunction and memory loss. There's also evidence suggesting a potential connection to Alzheimer's disease, though this is not conclusively proven. Skin contact with aluminum can cause irritation or allergic reactions in some individuals. It's important for workers to use proper protective equipment and follow safety guidelines to minimize these risks.</p>

- Q: Explain the impact of aluminum on the transportation system when it is incorporated into automobiles.

- <p>Aluminum has a significant impact on the transportation system when used in automobiles. It is lightweight, which improves fuel efficiency by reducing the overall weight of the vehicle. This reduction in weight leads to lower emissions, as less fuel is consumed. Aluminum's durability and resistance to corrosion also contribute to the longevity of vehicles, reducing the need for frequent repairs or replacements. Additionally, aluminum's recyclability helps in reducing waste and conserving resources, which is beneficial for environmental sustainability. Overall, the use of aluminum in automobiles enhances performance, reduces environmental impact, and promotes a more sustainable transportation system.</p>

- Q: What are the various electronic components that utilize aluminum as a primary material?

- <p>Aluminum is used in several types of electronic components due to its good thermal conductivity, lightweight, and corrosion resistance. Some of the common components include: 1. Capacitors: Aluminum electrolytic capacitors are widely used for their high capacitance and low cost. 2. Heat sinks: Aluminum is a popular choice for heat sinks due to its ability to dissipate heat efficiently. 3. Semiconductors: Aluminum is used in semiconductor manufacturing, particularly for interconnects and as a barrier layer. 4. Conductive adhesives: Aluminum-filled adhesives are used for bonding components in electronics. 5. Wires and cables: Aluminum wire is used in some applications due to its lower weight compared to copper. 6. Reflectors: Aluminum is used in light reflectors for its reflective properties. 7. Housings and enclosures: Aluminum is used in the construction of electronic device casings for its strength and lightweight properties.</p>

Send your message to us

High Quality Aluminum 3003/8011 Mill Price Aluminum Circle

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords