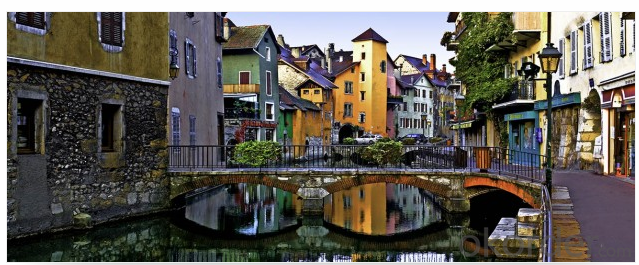

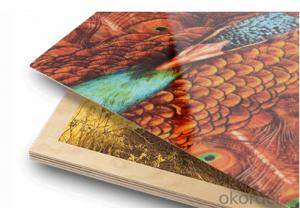

2016 HD Aluminium Metal Art Pictures Print on 4 By 8 Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 carton

- Supply Capability:

- 20000 carton/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description:

These Aluminum Panels can provide for many sizes and different color. It can suitable in many occasion, like company logo screen, show backdrop, home use, some gift use etc. We can also provide the heat press machine for transferring.

Features:

1. Extremely durable scratch resistant surface that is waterproof and can be cleaned easily with a damp cloth.

2. Eco-friendly & Terrific as a decoration.

3. Longest lasting photo medium in the current market.

4. The high definition, vibrant colors coupled with superior fade, moisture, stain & scratch resistant properties.

5. The image is infused into the coating to provide permanent protection and durability.

6. Excellent choice for commercial, fine art, and home decoration applications.

Making Process:

1. Get images from digital camera, memory card or scanner.

2. Print image with heat transfer paper and sublimation ink.

3. Lay down a teflon sheet and your panel, and another CLEAN teflon sheet on top, pre-press for 60 sec., 180℃, 0.3Mpa.

4. 60 seconds later. Wait the panel to cool.

5. Tape the transfer to the face of the substrate with heat resistent tape running parallel to the edge of the substrate.

6. Lay substrate face up, transfer on top on a piece of telfon sheet on lower platen.

7. Cover with one layer of fabric, preferably 100% polyester or poly-silk, to distribute pressure and reduce stress on the coating.

8. Press for the prescribed time is 130sec., temperature is 180℃ and pressure is 0.3Mpa.

9. When finished, remove the fabric and gently peel the taped transfer off the substrate without allowing it to slide or move.

10. Let the substrate to cool. Do not handle it until cool to reduce the chances of damaging the coating on the edges.

11. Enjoy your personal designed aluminum board!

- Q: What is the typical impact strength of aluminum sheets?

- The typical impact strength of aluminum sheets can vary depending on factors such as alloy composition, tempering, and thickness. However, generally, aluminum sheets have a moderate impact strength, making them suitable for many applications that require resistance to impact and denting.

- Q: What are the different forms of aluminum sheet available?

- There are several different forms of aluminum sheet available, including plain, embossed, perforated, and painted aluminum sheets.

- Q: Are aluminum sheets suitable for signage applications?

- Yes, aluminum sheets are suitable for signage applications. Aluminum is a lightweight and durable material, making it perfect for outdoor signs that need to withstand various weather conditions. It is resistant to rust and corrosion, which ensures the longevity of the sign. Aluminum sheets can be easily customized and cut into different shapes and sizes, allowing for versatile and creative signage options. Additionally, aluminum is a great material for digital printing and can provide high-quality graphics and images. Overall, aluminum sheets offer excellent durability, versatility, and aesthetic appeal, making them a popular choice for signage applications.

- Q: Are aluminum sheets suitable for insulation and soundproofing?

- No, aluminum sheets are not suitable for insulation and soundproofing as they are not effective in blocking heat transfer or sound waves.

- Q: What is aluminium plate L2-Y2?

- China plastic deformation of pure aluminum grades are 1080, 1080A, 1070, 107000A (L1), 1370, 1060, 1050 (L2), 1050A (L3), 1A50 (LB2), 1350, 1145, 1035 (L4), 1A30 (L4-1), 1100 (L5-1), 1200 (L-5), 1235. Iron and silicon are their major impurities and are increasing by the number of brands.2, Y2: indicates that the material is in a semi hard state

- Q: Can aluminum be either conductive or magnitized?

- Aluminium can conductive because it has low resistivity which is due to the three delocalized electron present in Aluminium structure. Aluminium cannot be magnetized because it does not exhibit ferro magnetism ( which is the ability of magnet to attract a metal).

- Q: What are the different methods for joining aluminum sheets?

- Depending on the desired outcome and specific application, there are various methods available for joining aluminum sheets. The following are some commonly used techniques: 1. Welding: Different welding techniques, such as Tungsten Inert Gas (TIG) welding, Metal Inert Gas (MIG) welding, and Resistance Spot Welding (RSW), can be employed to weld aluminum sheets. TIG welding is often preferred for thin sheets as it produces a strong and precise joint. MIG welding, on the other hand, is suitable for thicker sheets and allows for faster production rates. RSW involves passing an electric current through the sheets, melting the aluminum at the contact points, and then applying pressure to create a solid joint. 2. Mechanical Fasteners: Bolts, nuts, and screws can be utilized to join aluminum sheets, providing a reliable and sturdy connection. This method allows for easy disassembly if necessary. Rivets are another commonly used mechanical fastening method, where the sheets are secured using a rivet gun that deforms the rivet. 3. Adhesive Bonding: Specialized adhesives designed for aluminum bonding can be used to join sheets together. This method is often chosen for its ability to create a clean and seamless appearance, making it ideal for situations where aesthetics matter. Adhesive bonding also helps distribute stress evenly across the joint, reducing the risk of localized stress concentration. 4. Clinching: Clinching is a cold joining process that involves deforming the aluminum sheets using a punch, creating a mechanical interlock. This method is quick, cost-effective, and does not require additional materials like fasteners or adhesives. 5. Friction Stir Welding (FSW): FSW is a solid-state joining process that utilizes a rotating tool to generate friction between the aluminum sheets. The friction heats the material, making it pliable, and the rotating tool stirs the softened material together to form a solid joint. FSW is particularly suitable for joining thicker aluminum sheets. Each joining method has its own set of advantages and disadvantages. The choice of method depends on factors such as the desired strength, appearance, production rate, and specific requirements of the application.

- Q: Can aluminum sheets be anodized with custom colors?

- Yes, aluminum sheets can be anodized with custom colors. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of aluminum, and during this process, dyes can be applied to achieve a wide range of custom colors.

- Q: i bought a light fixture for my bathroom wall and the ground wire is aluminum and the existing ground wire in the wall is copper,so i would like to know if i can join them and if so,how?

- I doubt the ground wire is Aluminum, more likely it is tinned copper. Check by bending it, copper bends easier than aluminum, compare to the fixture wires. To connect copper wire to aluminum wire you need special conductive paste and connectors certified for CU/ AL.

Send your message to us

2016 HD Aluminium Metal Art Pictures Print on 4 By 8 Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 carton

- Supply Capability:

- 20000 carton/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords