201 Stainless Steel Sheet 2mm hot rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

201 hot rolled stainless steel sheet 2mm

NAME | |

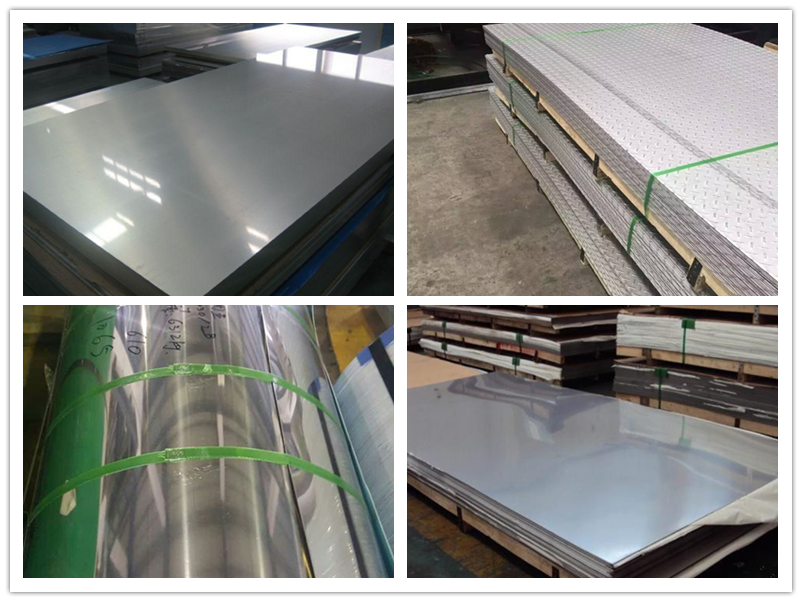

typ | Cold rolled;hot rolled |

thickness | 0.3-3mm;3mm-100mm |

Cold size | 1000mm*2000mm,1220mm*2440mm |

Hot size | 1500mm*6000mm |

Cold surface | 2B,BA,HL,8K,No.4,No.8 |

Hot surface | No.1 |

Material/Grade | 201,202,304,304L,321,316L,310S,317,4049L, etc. |

Standard | ASTMA240,ASTMA480,GB/T4237-1992,JIS |

Application | Auto or aircraft or construction industry,tableware,furniture , decoration for chemical equipment ,Industry purposes and building ornament, production manufacturing |

Place of Origin | Tianjin, China (Mainland) |

Brand Name | Tisco,Jisco,Baosteel,Lisco |

Technique | cold rolled ,hot rolled |

Certificate | ISO 9001:2008 |

Payment terms | T/T(recommended), L/c,western |

Leading time/Delivery Detail | Within 7-15 days after receipt of T/T or L/c at sight |

Packaging Detail | 1.with wooden pallets, or film covered, in the containers. 2.Export standard package or as the customers' demands. 3.seaworthy wooden cases, 4.with or without edge protector,steel hoop and seals, 5.export -ted standard package or as customers signal requirement |

Stock | Aways in stock |

Payment | 30% TT in advance, balance against copy B/L |

MOQ: | 1 TON |

Note

| We can produce other standard as the customers’ requirement

|

Producitivity | 10000Tons/Month |

1.We can supply you with reasonable and competitive price and good quality products. 2.If you are interested in any of products, please contact us for more information.

| |

Packaging & Shipping

Application

- Q: What is the minimum order quantity for stainless steel sheets?

- The minimum order quantity for stainless steel sheets can vary depending on the supplier and the specific type and size of the sheets. It is recommended to contact the supplier directly to inquire about their minimum order quantity.

- Q: Do stainless steel sheets have a warranty?

- Yes, stainless steel sheets generally come with a warranty. The duration and terms of the warranty may vary depending on the manufacturer and the specific product. It is always recommended to check with the supplier or manufacturer for the details of the warranty coverage. Typically, the warranty covers defects in material or workmanship and provides a replacement or repair of the stainless steel sheet if any issues arise within the specified warranty period. It is important to follow the manufacturer's care and maintenance instructions to ensure the validity of the warranty.

- Q: Are stainless steel sheets suitable for pharmaceutical cleanrooms?

- Yes, stainless steel sheets are highly suitable for pharmaceutical cleanrooms. Stainless steel is a preferred material in cleanroom environments due to its inherent qualities such as corrosion resistance, durability, and ease of cleaning. It is non-porous, making it resistant to bacteria, mold, and other contaminants. Additionally, stainless steel is able to withstand frequent sanitization procedures without deteriorating, making it a reliable choice for maintaining a clean and sterile environment in pharmaceutical cleanrooms.

- Q: What is the maximum temperature stainless steel sheets can withstand?

- The specific grade of stainless steel determines the maximum temperature that stainless steel sheets can endure. Typically, most stainless steel grades can handle temperatures up to approximately 1500°F (815°C) without significant oxidation or scaling. Nevertheless, some high-temperature stainless steel grades like 310 or 321 can endure temperatures up to 2100°F (1150°C) or even higher. To guarantee optimal performance and durability, it is crucial to consider the specific application and grade of stainless steel when determining its maximum temperature resistance.

- Q: Are stainless steel sheets suitable for medical implants?

- Yes, stainless steel sheets are suitable for medical implants. Stainless steel is commonly used in medical implants due to its excellent corrosion resistance, mechanical strength, and biocompatibility. It can be easily sterilized, is durable, and has a long track record of successful use in various medical applications.

- Q: Can stainless steel sheets be used for medical implants or devices?

- Yes, stainless steel sheets can be used for medical implants or devices. Stainless steel is a commonly used material in the medical field due to its high strength, corrosion resistance, and biocompatibility. It is particularly suitable for applications such as surgical instruments, orthopedic implants, and dental tools, where durability and hygiene are essential.

- Q: Are stainless steel sheets suitable for water tanks?

- Stainless steel sheets are indeed a great option for water tanks. Their resistance to corrosion makes them perfect for water storage. They won't react with the water or introduce any harmful substances into it. Additionally, stainless steel tanks are durable, require little maintenance, and have a long lifespan. They can handle high temperatures and extreme weather conditions without compromising their structural integrity. Moreover, stainless steel is non-porous, preventing the growth of bacteria and algae. These outstanding characteristics make stainless steel sheets a superb choice for water tanks in different settings, such as residential, commercial, and industrial environments.

- Q: Are stainless steel sheets suitable for water treatment facilities?

- Indeed, water treatment facilities find stainless steel sheets to be highly suitable. Known for its corrosion resistance, stainless steel proves to be essential in an environment where water and chemicals are consistently present. It effectively resists rust and degradation, guaranteeing the longevity and durability of the sheets. Moreover, stainless steel boasts ease of cleaning and maintenance, rendering it an ideal choice for facilities that necessitate regular hygiene and sanitation. Furthermore, this material exhibits remarkable resistance to heat and extreme temperatures, ensuring its performance even in demanding conditions. Additionally, stainless steel is non-reactive, meaning it does not release any harmful substances into the water during treatment processes. Consequently, it stands as a safe and reliable option for water treatment applications.

- Q: What are the applications of stainless steel sheets in the automotive industry?

- Stainless steel sheets are widely used in the automotive industry due to their numerous beneficial properties. These sheets find applications in various components and parts of automobiles, contributing to the overall performance, durability, and aesthetics of vehicles. One of the key applications of stainless steel sheets in the automotive industry is in the production of exhaust systems. Stainless steel is highly resistant to corrosion and heat, making it an ideal material for exhaust pipes. These sheets can withstand the high temperatures generated by the engine, ensuring longevity and reliability of the exhaust system. Additionally, stainless steel sheets are used in the manufacturing of automotive body panels. They provide excellent strength and rigidity, allowing for the production of lightweight yet sturdy body parts. Stainless steel's resistance to corrosion is also advantageous, as it ensures that the body panels do not degrade over time, even in harsh weather conditions. Furthermore, stainless steel sheets are employed in the production of fuel tanks and other fluid storage components. Stainless steel's corrosion resistance and ability to withstand high pressure make it a suitable material for these applications. The use of stainless steel in fuel tanks ensures that they remain leak-free and durable, leading to enhanced safety and longevity. Moreover, stainless steel sheets are utilized in the production of various interior and exterior trim parts. These include decorative elements such as grilles, trims, and accents, which enhance the aesthetics of the vehicle. Stainless steel's ability to be polished and finished to a high shine adds a touch of elegance and sophistication to the car's design. In summary, stainless steel sheets have numerous applications in the automotive industry. They are used in exhaust systems, body panels, fuel tanks, and trim parts, among others. The exceptional properties of stainless steel, such as corrosion resistance, heat resistance, and strength, contribute to the overall performance, durability, and aesthetics of automobiles.

- Q: How do I prevent fretting corrosion on stainless steel sheets?

- To prevent fretting corrosion on stainless steel sheets, you can take several measures. Firstly, ensure that the sheets are properly cleaned and free from any contaminants before installation. This includes removing any oils, dirt, or other substances that may contribute to corrosion. Additionally, applying a corrosion-resistant coating or a protective film can act as a barrier against fretting corrosion. It is also important to avoid excessive mechanical stress or movement between the sheets, as this can lead to fretting corrosion. Finally, maintaining a dry and clean environment, with controlled humidity levels, can significantly reduce the risk of fretting corrosion on stainless steel sheets.

Send your message to us

201 Stainless Steel Sheet 2mm hot rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords