Stainless Steel Sheet 304 2mm hot rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

High Quality Cold Rolled Stainless Steel Plate,Cold Rolled Stainless Steel Plate,Stainless Steel Sheet,

Specifications

We offer superior quality stainless steel sheets, which have earned us wide admiration in the world market.

| Material | Size | Thickness | Specification | Manufacturer |

| Stainless Steel | 1000 mm x 2000 mm, 1220 mm x 2440 mm (4' x 8'), 1220 mm x 4880 mm, 1250 mm x 2500 mm, 1500 mm x 3000 To 6300 mm, 2000 mm x 2000 To 10000 mm, | 0.1 mm To 150 mm | A-240 | TISCO,LISCO. |

Grades:

304, 304L, 316, 316L, 317L, 321, 316 Ti, 309, 310, 904L, 410, 420, 430, 431, 202, etc.

Sheet Finishing:

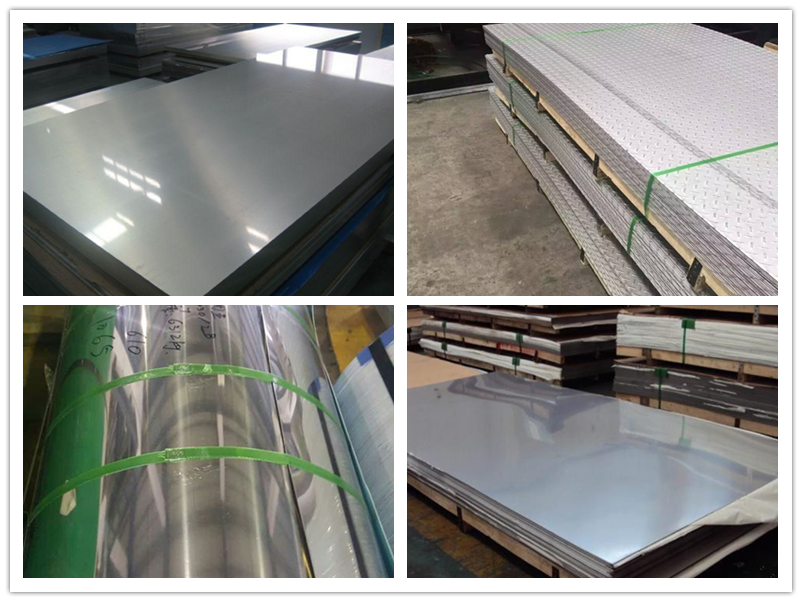

2B, 2D, HR, CR, BA (No. 8), No. 4, Satin (Met with PVC Coated)

Sheet & Plate In Form Of: Coils, foils, shim sheet, perforated sheet, chequered plate, strip, flats, blank (circle), ring (flange), etc.

Value Added Service:

Cladding, heat treatment.

Annealed & pickling, polish & buffing.

Rolling, cutting, bending, forging, minor fabrication, etc.

Test Certificate:

Manufacturer Test Certificate

Laboratory Test Certificate from Govt. Approved Lab.

Under Third Party Inspection with Excise Gate Pass to avail Modvat benefit.

Specialize:

Shim sheet, perforated sheet (round, square & oblong hole) & as per your drawing

Packaging & Shipping

Application

- Q: Can stainless steel sheets be bent?

- Stainless steel sheets have the capability to be bent. This material, known for its versatility, can be molded into different forms and designs, including bends. The capacity to bend stainless steel sheets relies on their thickness and composition. Generally, thinner sheets are more pliable and easier to bend, whereas thicker sheets might necessitate specialized tools and techniques. It is crucial to bear in mind that the bending procedure could potentially weaken the strength and durability of the stainless steel sheet. Therefore, careful thought should be given to the particular application and requirements before embarking on the bending of stainless steel sheets.

- Q: What are the different types of stainless steel sheet surface textures for decorative purposes?

- There are several types of stainless steel sheet surface textures that are commonly used for decorative purposes. These textures can enhance the overall aesthetic appeal of the stainless steel sheet and make it suitable for various applications. Some of the different types of stainless steel sheet surface textures include: 1. Brushed Finish: This texture is achieved by rubbing the stainless steel sheet surface with a fine abrasive material, resulting in a uniform satin-like appearance. Brushed finish is popular for its smooth and subtle texture, making it suitable for various decorative applications. 2. Mirror Finish: Also known as a highly reflective finish, the mirror finish is achieved by polishing the stainless steel sheet surface to a high gloss. This texture creates a mirror-like reflection and is often used in decorative applications where a sleek and modern appearance is desired. 3. Bead Blast Finish: This texture is created by blasting the stainless steel sheet surface with small glass beads, resulting in a matte and textured appearance. Bead blast finish is commonly used in decorative applications where a non-reflective and textured surface is desired. 4. Embossed Finish: This texture involves creating patterns or designs on the stainless steel sheet surface by stamping or pressing it with a patterned roller or plate. Embossed finishes can vary in pattern and depth, adding a visually appealing and tactile element to the stainless steel sheet. 5. Etched Finish: This texture is achieved by chemically etching the stainless steel sheet surface with an acid or other corrosive substances. Etched finishes can create various designs, patterns, or even images on the surface, making it ideal for decorative applications where intricate detailing is required. 6. Hairline Finish: This texture is created by mechanically polishing the stainless steel sheet surface with fine abrasive belts or brushes, resulting in a narrow and uniform textured pattern. Hairline finishes are commonly used in decorative applications where a subtle and elegant appearance is desired. These are just a few examples of the different types of stainless steel sheet surface textures available for decorative purposes. Each texture offers a unique visual and tactile quality, allowing for a wide range of design options when using stainless steel sheets for decorative applications.

- Q: What is the standard size of a stainless steel sheet?

- The size of a stainless steel sheet can vary depending on the manufacturer and the specific application. Different standard sizes are commonly available, such as 4 feet by 8 feet (1220mm by 2440mm) or 4 feet by 10 feet (1220mm by 3050mm). These dimensions are widely used in industries like construction, manufacturing, and fabrication. Moreover, stainless steel sheets are also available in various thicknesses, ranging from 0.4mm to 6mm or more, depending on the intended use and requirements. It's worth noting that manufacturers can provide custom sizes and dimensions for specific projects or applications that require non-standard sizes.

- Q: Can stainless steel sheets be used for conveyor belts?

- Yes, stainless steel sheets can be used for conveyor belts. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for various industrial applications, including conveyor belts. Stainless steel sheets can withstand high temperatures, heavy loads, and abrasive materials, making them ideal for conveying purposes. Additionally, stainless steel's smooth surface allows for easy movement of products and minimizes friction, resulting in efficient and reliable conveyor operations.

- Q: Can stainless steel sheets be used for swimming pool installations?

- Certainly! Stainless steel sheets are a great option for swimming pool installations. With their exceptional durability and resistance to corrosion, stainless steel is well-suited for use in pools. It can withstand rust, stains, and the various chemicals usually present in pool water, making it a dependable choice for long-term usage. In fact, stainless steel sheets are frequently employed for constructing pool walls, floors, and other crucial components due to their ability to endure the challenging conditions typical of pool environments. Moreover, stainless steel possesses a sleek and contemporary look that contributes to the pool's overall aesthetic appeal.

- Q: What are the different types of edge finishes available for stainless steel sheets?

- There are several types of edge finishes available for stainless steel sheets, including the straight edge, beveled edge, rounded edge, and hemmed edge.

- Q: Can stainless steel sheets be used for elevator handrails?

- Yes, stainless steel sheets can be used for elevator handrails. Stainless steel is a popular material for handrails due to its durability, strength, and resistance to corrosion. Elevator handrails are subject to constant use and exposure to various elements, making stainless steel an ideal choice. Additionally, stainless steel can be easily cleaned and maintained, ensuring a hygienic and aesthetically pleasing environment for elevator users.

- Q: What are the applications of stainless steel sheets in the automotive industry?

- Stainless steel sheets in the automotive industry are used for various applications such as body panels, exhaust systems, fuel tanks, and structural components. They provide excellent corrosion resistance, high strength, and durability, making them ideal for withstanding harsh conditions and ensuring long-lasting performance in vehicles. Additionally, stainless steel sheets can be easily formed and welded, allowing for precise shaping and customization according to the specific requirements of different automotive parts.

- Q: Do stainless steel sheets require any special handling during installation?

- Special handling is necessary when installing stainless steel sheets. Here are some important factors to consider: 1. Prevent Contamination: Stainless steel is easily contaminated by carbon steel, dirt, and grease. It is vital to ensure that the installation area is clean and free from potential contaminants. Additionally, the tools used for installation should be clean and free from other metals. 2. Protect from Scratches: Stainless steel sheets are prone to scratching during installation. It is crucial to handle them carefully and use protective coverings or wraps to prevent any damage. Furthermore, using non-abrasive tools and avoiding dragging or sliding the sheets across surfaces can help maintain their integrity. 3. Use Proper Fixing Techniques: Mechanical fasteners or adhesives are typically used to secure stainless steel sheets. It is essential to follow the manufacturer's recommendations or industry best practices for the specific installation method. This includes using the correct type and size of fasteners and ensuring they are properly tightened without causing damage. 4. Account for Expansion and Contraction: Stainless steel sheets expand or contract with temperature changes. During installation, it is necessary to provide adequate clearance or use expansion joints to accommodate this movement. Failure to consider thermal expansion can result in buckling, warping, or stress on the sheets. 5. Prevent Galvanic Corrosion: Direct contact between stainless steel sheets and dissimilar metals, especially those with higher galvanic potential, can lead to galvanic corrosion. To prevent this type of corrosion, it is important to use compatible materials and insulate stainless steel sheets from direct contact with other metals. By adhering to these special handling guidelines, stainless steel sheets can be installed correctly, ensuring their aesthetic appeal and durability are maintained over time.

- Q: What are the different types of stainless steel sheet finishes for sanitary applications?

- For sanitary applications, various types of stainless steel sheet finishes are commonly used. These finishes are specifically designed to offer a smooth and clean surface that resists corrosion and bacteria growth. 1. One commonly used finish for stainless steel sheets in sanitary applications is the #4 Brushed Finish. It presents a brushed appearance that creates a consistent and uniform texture. This finish is easy to clean and maintain, making it perfect for environments where hygiene is of utmost importance. 2. Another option is the #8 Mirror Finish, which boasts a highly reflective surface resembling a mirror. It is visually appealing and easy to clean due to its smooth and shiny nature. However, it is worth noting that this finish may show scratches and fingerprints more readily than others. 3. The 2B Finish is generally applied to stainless steel sheets that will undergo further processing, such as fabrication or welding. It presents a dull and smooth appearance, providing a suitable base for additional treatments or coatings. 4. The Satin Finish, also known as a No. 4 finish, offers a low luster and smooth texture. It is frequently used in sanitary applications where a clean and aesthetically pleasing surface is desired. 5. A Bead Blast Finish is achieved by subjecting the stainless steel sheet to fine glass beads. This process results in a non-reflective surface that is uniform and easy to clean. It also provides resistance to corrosion, making it a popular choice for food processing plants and pharmaceutical facilities. 6. Lastly, the Electropolished Finish involves an electrochemical process that removes a thin layer from the stainless steel surface, leaving behind a smooth and shiny appearance. This finish offers a high level of cleanliness and resistance to corrosion, making it suitable for sanitary applications in the pharmaceutical and biotech industries. To ensure the best possible outcome, it is crucial to consider the specific requirements of the sanitary application when selecting the appropriate stainless steel sheet finish. Factors such as corrosion resistance, ease of cleaning, and aesthetic appearance should be taken into account.

Send your message to us

Stainless Steel Sheet 304 2mm hot rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords