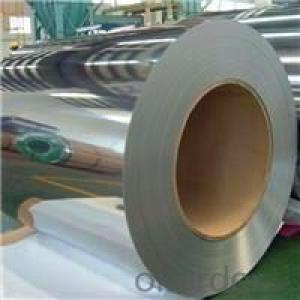

201 Cold-Rolled Stainless Steel Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description:

201 stainless steel has a certain acid and alkali resistance, high density, polishing without bubbles, pinhole free etc., is in the production of a variety of watchcase, watchband bottom cover quality materials. Mainly used in decorative tubes, industrial tubes, some of the shallow stretching of the productsThe cold rolling is the steel plate with the thickness of the target under the recrystallization temperature at the recrystallization temperature.. Compared with hot rolled plate, the thickness of cold rolled sheet is more accurate, and the surface is smooth and beautiful.

2.Product characteristic:

The application of the cold-rolled plate is widely used, such as the automobile manufacture, the electric products, the locomotive and the vehicle, the aviation, the precision instrument, the food can, etc.. Cold rolled sheet is the abbreviation for common carbon structural steel cold rolling plate, also known as cold plate, commonly known as cold plate, sometimes it is mistakenly written cold plate. The cold plate is made of ordinary carbon structural steel hot rolled strip, and after further cold rolling, the steel plate with the thickness of less than 4mm is made.. Due to the rolling at room temperature, and does not generate tin oxide. Therefore, good surface quality of cold plate, high size precision, coupled with the annealing treatment, the mechanical properties and processing properties are better than those of hot-rolled thin steel plate, in many areas, especially household electrical appliance manufacturing field, has gradually use it instead of hot rolled thin steel sheet.

3.Specification:

Tensile strength: 520MPa

Yield strength: 275MPa

Elongation: 55 to 60%

Modulus of elasticity: 29000000 psi is: 203000MPa

Hardness requirements (the hardness of the MPa) HRB<183N/mm2

Density: inch.280lbs/cubic (density 7.93g/cm3)

4.Reference picture:

- Q: im buying a new guitar,, it has a built in tuner and its semi acoustic (can be plugged into an amplifier) ,, im trying to choose which strings are better ,, steel or nylon..?

- Musical style speaks volumes when it comes to this issue. Those who want high volume will be unhappy with unamplified nylon string guitars. From my perspective, the basic difference between steel and nylon is this: steel strings ring and nylon strings resonate. The volume produced by steel is generally much greater than nylon but, to my way of thinking, the sound resonance produced by the wood of your guitar is largely masked by steel strings. If you have a decently made guitar (generally, around a thousand dollars and up), the sound interplay between the wood and the strings in a nylon guitar is magical across the entire frequency range. With a steel string guitar, the sound produced by the vibrating string overpowers the wood resonance at all but low frequencies. Personally, I'll take a nylon string guitar any day for the sensitivity gained from the interplay between wood and vibrating string.

- Q: How are steel coils used in the production of construction machinery?

- Steel coils are used in the production of construction machinery as they are a primary raw material for manufacturing various components such as structural frames, chassis, and other heavy-duty parts. These coils are typically processed and fabricated through cutting, bending, welding, and shaping techniques to create the required components that form the foundation of construction machinery.

- Q: What are the pros with stainless steel? You don't have to oil them as much or you don't have to oil them at all?Is the rifling in the barrel typically stainless steel as well? if so, is this better accuracy or does the rifling last longer then conventional?are they worth the extra money?Thanks for any info you can provide!

- stainless steel is a alloyed steel that resist rust and corrosion. show it enough salt (sea spray or sweat) and it will pit Stainless steel goes all the way through ...it's not a coating like nickle-plate. the inside of a stainless barrel is stainless and they hold up just as well as carbon steel barrels. Extra money? Stainless is pretty popular in new production and the price is not that much different than comparable guns in blue. Oil OK... they do hold up better to salt and sweat than bluing...and there is not coating or plating that can wear off. Down side... the reflect light. Some can be a bit to shiny for some situations.

- Q: What is the role of steel coils in the production of storage shelves?

- Steel coils play a crucial role in the production of storage shelves as they serve as the primary material for manufacturing the shelf frames and support structures. These coils are processed and formed into various components, such as beams and brackets, which provide strength and durability to the shelves. By using steel coils, storage shelves are able to withstand heavy loads and ensure long-lasting performance in commercial and industrial settings.

- Q: How can defects in steel coils be detected?

- Defects in steel coils can be detected through various methods such as visual inspection, ultrasonic testing, magnetic particle inspection, eddy current testing, and radiographic testing. These techniques help identify surface defects, internal flaws, cracks, or any other abnormalities that may affect the quality and strength of the steel coils.

- Q: and which one is better?i'm looking into buying some aftermarket headers, but companies make them in both chrome and stainless steel

- I know nothing of aftermarket headers so can't help you there, but - chrome is a coating on metal. Stainless Steel is a type of metal.

- Q: What are the different types of steel coil edge conditioning methods?

- There are several different types of steel coil edge conditioning methods, including slitting, trimming, deburring, chamfering, and edge rolling.

- Q: I need to penetrate steel on my car but don't know which bit to use. Are there special bits for steel?

- Yes, they'll be marked HSS, High Speed Steel.

- Q: Alright...Please tell me what I can and can't buy for Steel Legion in detail(Much Detail please)Ogryns.Las canons.The problem I'm having is that they don't have steel Legion Uniform..does it matter?1.I also heard that you can't use Commisar Yarrick.(So what could I use?)2.What are my Hq choices,Fast attack,Heavy Support,Elite etc.3.Steel Legion has a Commisar....(Do I buy one for each squad of Steel Legion or one?)Please in detail what should I buy...I don't have the codex yet but will soon!!4.I also heard that if I get Steel Legion I need a transport for everything?(Is this true?)5.Please be detail on what i can't and can buy!!(Please like HQ Squad leader,Sargent)

- here are a couple of things about the steel legion. you should have a lot of mechanized units, have chimaras for rvery squad if posible, artillery fire helps a hell of a lot. also sentinals and leman russes and hell hounds also help. if in apocolypse, use banblades and titans. storm trooper squads should be your base squadrons. put them in chimeras and get near the action, drop 'em off and rapid fire like CRAZY!!! the steel legion loves heavy weapons so remember to get some heavy weapons platforms. there favourite weapons are grenade and missle launchers. there is also an officer you can buy with a power sword with the steel legion look. steel legion are big xeno hunters. because commisar is a ork killer you should be allowed to field him. ratling/ sniper squads also help and if you can get a vindicare assassin that is very useful.

- Q: What are the different types of corrosion protection for steel coils?

- There are various types of corrosion protection methods for steel coils. Some common ones include galvanization, which involves coating the steel with a layer of zinc; painting or coating the steel with corrosion-resistant materials such as epoxy or polyurethane; and applying a protective film or oil to create a barrier against moisture and corrosive elements. Additionally, using corrosion inhibitors in the form of chemicals or additives can also provide protection against corrosion. Ultimately, the choice of corrosion protection method depends on factors such as the expected exposure conditions and the desired level of protection.

Send your message to us

201 Cold-Rolled Stainless Steel Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords