Stainless Steel Coil Cold Rolled 201 with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Stainless Steel Coil Cold Rolled 201 Descriptions

Stainless Steel 201 is a new kind of Austenite stainless steel by used Mn, N replace Ni. The steel has good corrosion resistance and hot / cold processing performance, instead of 304 stainless steel products for used in the not high of corrosive environment, such as indoor, inland city outdoor etc.

2. Main Features of the Stainless Steel Coil Cold Rolled 201

Standard: JIS, SUS, AISI, ASTM

Grade: 201-J1, 201-J4, AISI201, AISI202

Finish: BA, 2B, 8K, NO.3, NO.4, HL

MOQ: 25 Metric Tons

Hardness: Low Hard(190 HV Max); Half Hard(240-280HV); Full Hard(42-60 HRC)

Ship Term: FOB any port, China or CFR Destination port

Delivery Time: 15 to 20 day after the receive the deposit or 100%LC

Payment Terms: TT 30% for deposit, Balance against the copy of B/L, or 100%LC

Packaging: By wooden pallet, wooden case or according to customer's request

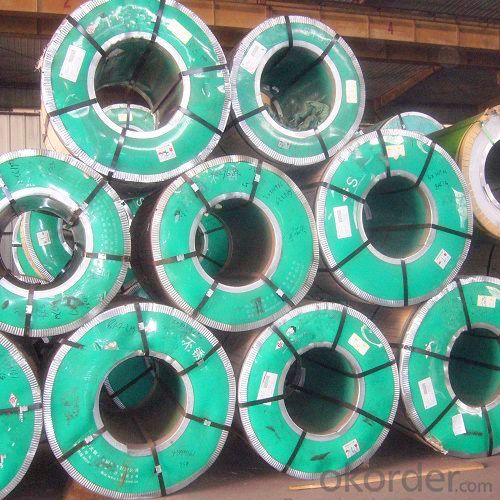

3. Stainless Steel Coil Cold Rolled 201 Images

4. Stainless Steel Coil Cold Rolled 201 Specifications

Mechanical Property Contrast | YS (Mpa) | TS (Mpa) | EL(%) | HV | REMARK |

Stainless Steel 201 | 426 | 880 | 52 | 224 | 1.0t |

Stainless Steel 304 | 285 | 710 | 58 | 165 | 1.0t |

Stainless Steel 200 Series Chemicals Contrast (wt. %) | ||||||||

Chemicals | C | Si | Mn | Cr | Ni | N | Other | |

205 | 0.12-0.25 | ≤0.75 | 14.0-15.0 | 16.5-18.0 | 1.0-1.75 | 0.32-0.4 | ||

JIS, | 201 | ≤0.15 | ≤1.0 | 5.5-7.5 | 16.0-18.0 | 3.5-5.5 | ≤0.25 | - |

201L | ≤0.03 | ≤0.75 | 5.5-7.5 | 16.0-18.0 | 3.5-5.5 | ≤0.25 | - | |

202 | ≤0.15 | ≤1.0 | 7.5-10.0 | 17.0-19.0 | 4.0-6.0 | ≤0.25 | - | |

201LN | ≤0.03 | ≤0.75 | 6.4-7.5 | 16.0-17.5 | 4.0-5.5 | 0.1-0.25 | Cu≤1.0 | |

India | 201-J1 | ≤0.08 | ≤0.75 | 7.0-8.0 | 15.0-17.0 | 4.0-5.0 | ≤0.1 | Cu≤1.5 |

201-J3 | ≤0.08 | ≤0.75 | 9.0-10.5 | 14.0-16.0 | 2.0-3.0 | ≤0.15 | Cu≤2.0 | |

201-J4 | ≤0.10 | ≤0.75 | 8.5-10.0 | 15.0-16.0 | ≤1.2 | ≤0.2 | Cu≤2.0 | |

America | 204 | ≤0.03 | ≤1.0 | 7.0-9.0 | 15.0-17.0 | 1.5-3.0 | 0.15-0.3 | (Cu) |

H400 | ≤0.10 | ≤1.0 | 6.0-9.0 | 17.0-19.5 | ≤3.5 | ≤0.3 | - | |

Japan | YUS130S | 0.09 | 0.5 | 11.0 | 18.0 | 6.5 | 0.35 | - |

NTK S-4 | 0.17 | 0.43 | 14.7 | 17.7 | 1.3 | 0.35 | - | |

NM15M | 0.08 | 0.8 | 14.5 | 17.0 | 4.3 | 0.33 | - | |

Europe America | 219 | ≤0.04 | ≤0.75 | 8.0-10.0 | 19.0-21.5 | 5.5-7.5 | 0.15-0.4 | - |

Cromanite | ≤0.08 | ≤1.0 | 9.5-11.0 | 18.0-20.0 | ≤1.0 | 0.4-0.6 | - | |

201 Surface | Characteristic and Application of Stainless Steel Coil Cold Rolled 201 |

2B | The surface brightness and flatness of 2B is better than 2D then through a special surface treatment to improve its mechanical properties,2B could nearly Satisfy comprehensive uses |

No.4 | Polished with abrasive belt of grit#150#180, have better brightness with discontinuous coarse stria, but thinner than NO.3, are used as bathtub buildings inner and electrical appliances kitchen utensils and food processing. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness like mirror kitchen apparatus, etc. |

8K | The product have excellent brightness and prefer bright can be the mirror. |

5. FAQ of Stainless Steel Coil Cold Rolled 201

Q: Are you factory or trader?

A: We certainly are stainless steel manufacturer and have processing plant.

Q: Can you provide mill test certificate?

A: Yes! Mill test certificate for both hot rolled raw material coils and cold rolled coils are available.

Q: Can you make DDQ (Deep drawing quality)?

A: Yes. Our material has been widely used for producing stainless steel pots and stainless steel sinks, which have strict request for good deep drawing quality.

Q: How to visit your factory?

A: Most of the main cities in the world have flight to Beijing; you can take flight to Beijing first, then we will lead you to our Wuxi mills.

Q: How about your company?

A world class manufacturer & supplier of castings forging in stainless steel, is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 90000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service are available, all according to customer’s requirements.

Q: How to guarantee the quality of the products?

A: We have established the international advanced quality management system,every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can stainless steel strips be used in heat recovery systems?

- Yes, stainless steel strips can be used in heat recovery systems. Stainless steel is a popular choice for heat recovery systems due to its excellent corrosion resistance and high temperature resistance. It can withstand the high temperatures and harsh environments typically found in heat recovery systems. Additionally, stainless steel has good thermal conductivity, allowing for efficient heat transfer. Its strength and durability make it a reliable choice for use in heat recovery systems, ensuring long-term performance and minimal maintenance requirements.

- Q: Are stainless steel strips suitable for storage tanks?

- Indeed, storage tanks can benefit from the use of stainless steel strips. This material is renowned for its durability and resistance to corrosion, making it an ideal choice for the storage of a wide range of substances. It boasts remarkable protection against rust, oxidation, and chemical reactions, thus ensuring the integrity of the stored materials. Furthermore, stainless steel strips are recognized for their robustness and stability, providing structural support to storage tanks. Moreover, stainless steel is easily cleaned and maintained, reducing the risk of contamination or degradation of the stored substances. In conclusion, stainless steel strips offer a dependable and enduring solution for storage tanks across various industries, including food and beverage, pharmaceuticals, and chemical storage.

- Q: What are the different types of surface finishes for stainless steel strips?

- Stainless steel strips usually undergo different types of surface finishes to improve their appearance, enhance their durability, and increase their resistance to corrosion. Below are some common finishes: 1. Mill Finish: The stainless steel strip is left in its original state after production, resulting in a non-reflective and dull appearance. It may have visible imperfections or marks from manufacturing. 2. No. 1 Finish: Also called HRAP (hot-rolled annealed and pickled), this finish involves annealing the stainless steel strip and pickling it in acid. It creates a smooth, reflective surface with a slightly matte look. No. 1 finish is frequently used in industrial applications where appearance is not a primary concern. 3. No. 2B Finish: Achieved by cold-rolling the stainless steel strip and subsequent annealing and pickling, this finish offers a bright, semi-reflective surface. It strikes a balance between appearance and corrosion resistance, making it suitable for kitchen appliances and architectural elements. 4. No. 4 Finish: Also known as brushed or satin finish, this finish is obtained by mechanically polishing the stainless steel strip with abrasive materials. It results in a smooth, matte appearance with fine parallel lines, giving it a brushed texture. No. 4 finish is commonly used for decorative purposes like furniture, elevator panels, and trims. 5. No. 8 Finish: Referred to as mirror finish, this finish is achieved by polishing the stainless steel strip to create a highly reflective surface. It has a mirror-like appearance with excellent reflectivity. No. 8 finish is often employed in architectural and decorative applications that require a polished, high-end look, such as signage, jewelry, and automotive trims. Apart from these primary surface finishes, there are also specialized finishes available for specific applications, such as embossed, patterned, and colored finishes. These finishes further enhance the aesthetic appeal and functionality of stainless steel strips in various industries.

- Q: Are stainless steel strips resistant to corrosion?

- Stainless steel strips possess corrosion resistance due to their composition. They consist of iron, chromium, and other elements that create a protective layer on the metal's surface. This layer, referred to as a passive film, acts as a barrier between the metal and oxygen and moisture, which are the primary factors behind corrosion. The formation of this protective film is attributed to the chromium content in stainless steel. The higher the chromium content, the greater the corrosion resistance. Consequently, stainless steel strips are renowned for their exceptional ability to withstand corrosion, rendering them suitable for numerous applications across diverse industries.

- Q: Can stainless steel strips be used for heat exchanger plates?

- Yes, stainless steel strips can be used for heat exchanger plates. Stainless steel is a popular choice for heat exchangers due to its excellent corrosion resistance, high strength, and thermal conductivity. The strips can be formed into the required shape and size, making them suitable for use as heat exchanger plates.

- Q: Are stainless steel strips resistant to chlorine corrosion?

- Yes, stainless steel strips are generally resistant to chlorine corrosion due to their high chromium content which forms a protective oxide layer on the surface, preventing the metal from reacting with chlorine.

- Q: Can stainless steel strips be used in outdoor signage?

- Yes, stainless steel strips can be used in outdoor signage. Stainless steel is highly resistant to corrosion and weathering, making it a durable material for outdoor applications. It can withstand exposure to harsh environmental conditions, including rain, sunlight, and temperature fluctuations, without losing its aesthetic appeal or structural integrity. Furthermore, stainless steel is easily customizable and can be engraved, etched, or painted to create attractive and long-lasting outdoor signage.

- Q: Are stainless steel strips suitable for brewery tanks?

- Yes, stainless steel strips are highly suitable for brewery tanks. Stainless steel is a popular choice for brewery equipment due to its excellent corrosion resistance, durability, and hygienic properties. The use of stainless steel strips ensures that the tanks are resistant to rust, staining, and chemical reactions, making them ideal for storing and fermenting beer. Additionally, stainless steel is easy to clean, which is crucial for maintaining the quality and flavor of the beer. Therefore, using stainless steel strips in brewery tanks is a reliable and practical choice for the brewing industry.

- Q: Can stainless steel strips be used for architectural sculptures?

- Indeed, architectural sculptures can utilize stainless steel strips. Stainless steel, known for its versatility and durability, can easily be shaped and molded into various forms. Its resistance to corrosion makes it an ideal material for outdoor sculptures, as it can endure harsh weather conditions without rusting or deteriorating. By cutting, bending, and welding stainless steel strips, intricate designs and one-of-a-kind sculptures can be crafted. The strips can be manipulated into different shapes, such as curves, waves, or straight lines, offering limitless creative possibilities. Moreover, stainless steel can be polished or brushed to achieve different finishes, granting the sculptures a sleek and contemporary appearance. Architectural sculptures often necessitate materials that are not only visually appealing but also long-lasting and low-maintenance. Stainless steel fulfills these requirements, making it an outstanding choice for architectural sculptures. Its strength and corrosion resistance render it suitable for both indoor and outdoor installations. Furthermore, the reflective surface of stainless steel can produce captivating visual effects, particularly when paired with lighting. The sculpture can capture and reflect the surrounding environment, enhancing its visual impact and generating a dynamic and captivating experience for spectators. In conclusion, there is no doubt that stainless steel strips can be employed to create architectural sculptures. Their versatility, durability, and aesthetic appeal make them a favored option for artists and architects seeking to fashion distinctive and enduring sculptures.

- Q: What are the factors that affect the corrosion resistance of stainless steel strips?

- The corrosion resistance of stainless steel strips can be affected by several factors. These factors include the composition of the alloy, the formation of a passive film, the surface finish, environmental conditions, stress corrosion cracking, and the manufacturing processes. 1. The corrosion resistance of stainless steel depends on its alloy composition. Stainless steel is typically made up of iron, chromium, and other elements like nickel, molybdenum, and nitrogen. The higher the chromium content, the better the corrosion resistance. Other alloying elements also contribute to the overall corrosion resistance. 2. When stainless steel is exposed to oxygen, it forms a protective film on its surface. The stability and thickness of this film depend on factors like alloy composition, surface condition, and environmental conditions. Any damage to the film can compromise the corrosion resistance. 3. The surface finish of stainless steel strips can greatly impact their corrosion resistance. Smooth and polished surfaces are less susceptible to corrosion compared to rough surfaces, as they provide fewer areas for corrosive agents to attack. 4. The environment in which stainless steel strips are used can significantly affect their corrosion resistance. Factors like temperature, humidity, pH level, and the presence of corrosive agents like chloride ions or sulfur compounds can accelerate corrosion. Stainless steel strips used in marine, industrial, or highly corrosive environments may require higher corrosion resistance. 5. Stress corrosion cracking is a type of corrosion that stainless steel can be susceptible to, especially in environments containing chlorides or sulfides. This type of corrosion occurs due to the combined effects of tensile stress and corrosive agents, leading to the formation of cracks. The susceptibility to stress corrosion cracking can vary depending on the alloy composition and environmental conditions. 6. The manufacturing processes and heat treatment involved in producing stainless steel strips can also affect their corrosion resistance. Improper heat treatment or inadequate manufacturing processes can result in a decrease in corrosion resistance. In conclusion, the corrosion resistance of stainless steel strips is influenced by various factors, including alloy composition, passive film formation, surface finish, environmental conditions, stress corrosion cracking susceptibility, and manufacturing processes. It is important to consider these factors when choosing the appropriate grade of stainless steel for specific applications to ensure optimal corrosion resistance.

Send your message to us

Stainless Steel Coil Cold Rolled 201 with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords