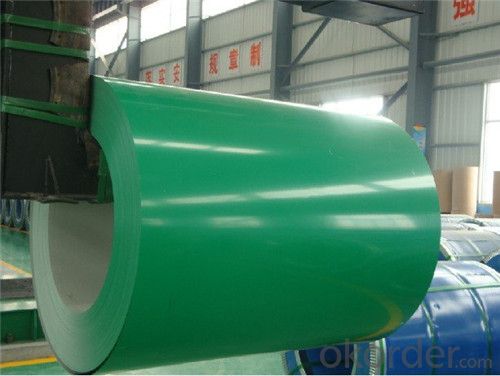

color Coated Galvanized Cold Rolled steel coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

NAME:

Prepainted Steel Coil\Colour Coated Coil\Coil coated steel\PPGI

SIZE:

Thickness: 0.18-1.50mm

Width: 10mm-1500mm(STD914mm,1000mm, 1200mm, 1219mm, 1250mm, 1500mm)

Thickness tolerance: +/-0.05 mm

Width tolerance: -2.0/5.0mm

ZINC, PAINT & COLOR:

Zinc coating: 60-275G/M2

Paint thickness: Top 15-25um + Back 5-10um

Paint: Epoxy Polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester

Color: As the RAL color standard or customer's sample

STANDARD:

JIS G 3312, ASTM A755, EN10169,GB/T2518

Base sheet: Galvanized steel coils\ Galvalume steel, such as SGCC, CGCC, DX51D+Z, Q195,etc

Quality: CQ DQ

Lifespan: 10-15 years

APPLICATION:

Outdoor: Roof\ Roof structure\Surface sheet of balcony\ Frame of window\Door\Door of garage\Roller shutter door\Booth\Persian blinds\Cabana\Refrigerated wagon and so on.

Indoor: Door\Isolater\Frame of door\Light steel structure of house\Sliding door\Folding screen\Ceiling\ Internal decoration of toilet and elevator.

Building accessories: Window panels, signboards

Home appliances: Oil/gas boilers, rice buckets, portable gas burners, etc.

| Commodity : | High Quality PrePainted Galvanized Steel Coil |

| Materials Grade: | SGCC ,CGCC ,DX51D+Z ,SGLCC |

| Thickness : | 0.17-1.2mm |

| Width : | 914mm,1219mm,1000mm,1220mm,1250mm ( can cut to strip above 30mm width ) |

| Zinc coating : | 60-275g/sqm |

| Surface Structure: | Galvanized Or Aluzinc |

| Color : | RAL No. or Sample color |

| Painting : | Top : 5micron primer +15-20microns polyester Back : 5-8microns primer epoxy |

| Coil Weight : | 2-6mts |

| Payment term : | TT ,L/C AT SIGHT , USANCE L/C ,D/P |

| Shipment : | 20 feet container or bulk ship |

| Remark : | We accept the third-party inspection ,such as SGS , INSPECTORATE ,CIQ |

- Q: How are steel coils used in the manufacturing of shock absorbers?

- Steel coils are used in the manufacturing of shock absorbers as they provide the necessary spring force to absorb and dampen the impact from road irregularities. The coils are designed to compress and expand under pressure, allowing the shock absorber to absorb and dissipate the energy generated during vehicle movement, resulting in a smoother and more controlled ride.

- Q: What are the different types of steel coil grades and specifications?

- There are several different types of steel coil grades and specifications available in the market. These grades and specifications are designed to meet various industry requirements and applications. Some of the commonly used steel coil grades and specifications are: 1. Hot Rolled Steel Coils: These coils are produced by heating the steel above its recrystallization temperature and then rolling it at a high temperature. Hot rolled steel coils are commonly used in applications where dimensional accuracy and surface finish are not critical. 2. Cold Rolled Steel Coils: Cold rolled steel coils are produced by further processing hot rolled coils through cold reduction mills. This process results in improved surface finish, tighter tolerances, and higher strength compared to hot rolled coils. Cold rolled steel coils are widely used in automotive, construction, and electrical industries. 3. Galvanized Steel Coils: Galvanized steel coils are coated with a layer of zinc to protect them from corrosion. This process, known as galvanization, enhances the durability and longevity of the steel coils. Galvanized steel coils are commonly used in applications such as roofing, fencing, and automotive body parts. 4. Stainless Steel Coils: Stainless steel coils are made from a combination of iron, chromium, and other elements that provide excellent corrosion resistance and high strength. These coils are widely used in industries such as food processing, chemical, and medical, where hygiene and corrosion resistance are critical. 5. High-strength Low-alloy (HSLA) Steel Coils: HSLA steel coils are designed to have higher strength and improved formability compared to conventional carbon steels. These coils are commonly used in structural and transportation applications, where weight reduction and high strength are required. 6. Electrical Steel Coils: Electrical steel coils, also known as silicon steel or transformer steel, are specifically designed for use in electrical equipment such as transformers, motors, and generators. These coils have low core losses and high magnetic permeability, making them ideal for efficient energy transfer. 7. Tool Steel Coils: Tool steel coils are specially formulated to have high hardness, wear resistance, and toughness. These coils are commonly used in the manufacturing of cutting tools, dies, and molds. These are just a few examples of the various types of steel coil grades and specifications available in the market. The selection of the appropriate grade and specification depends on the specific application requirements, such as strength, corrosion resistance, formability, and surface finish.

- Q: What are the common methods of protecting steel coils from corrosion?

- There are several common methods used to protect steel coils from corrosion. 1. Coating: One of the most effective methods is to apply a protective coating on the surface of the steel coil. Various types of coatings such as paint, epoxy, or zinc can be used to create a barrier between the steel and the corrosive environment. These coatings provide excellent corrosion resistance and prevent moisture and oxygen from reaching the steel surface. 2. Hot-dip galvanizing: This method involves immersing the steel coil in a bath of molten zinc, which creates a thick layer of zinc coating on the surface. The zinc coating acts as a sacrificial barrier, protecting the steel from corrosion. Hot-dip galvanizing is particularly effective in harsh environments or for long-term outdoor exposure. 3. VCI (Volatile Corrosion Inhibitor) packaging: VCI packaging is a method where steel coils are wrapped in a specially designed film or paper that contains volatile corrosion inhibitors. These inhibitors vaporize and form a protective layer on the surface of the steel, preventing corrosion. VCI packaging is commonly used for short-term storage or transportation of steel coils. 4. Desiccants: Moisture is a major contributor to corrosion. Therefore, using desiccants such as silica gel or activated alumina can help absorb moisture and maintain a dry environment around the steel coils. Desiccants are often used in conjunction with other protective methods to enhance corrosion protection. 5. Proper handling and storage: Proper handling and storage practices can significantly reduce the risk of corrosion. Steel coils should be stored in a dry environment away from moisture sources. They should also be handled with clean gloves to prevent the transfer of corrosive contaminants. Regular inspection and maintenance of the storage area are essential to identify and address any potential corrosion risks. By employing one or a combination of these methods, steel coils can be effectively protected from corrosion, ensuring their durability and integrity.

- Q: How are steel coils used in the production of power transmission towers?

- Steel coils are used in the production of power transmission towers as they are rolled and formed into the required shapes and sizes to create the structural components of the towers. The coils are processed and cut into specific lengths, which are then welded or bolted together to construct the tower sections. The robustness and strength of steel make it an ideal material for transmitting large amounts of electricity over long distances, ensuring the stability and reliability of power transmission towers.

- Q: I have a carbon steel file that I want to bend in a letter C shape. So, what is the malliable temperature? If it's low, could it be done in a camp fire?

- It needs to be RED hot, the hotter the better. Yes you can use a camp fire if you put the file directly in the hottest part of the coals, but it'll take about 5-10 minutes to heat. Charcoal briquettes would probably work better as a heat source. You can use something like a blow dryer to intensify the coals, that might help. You'll also need a bench vice, and the biggest pair of pliers you can find, for leverage. Bending steel's not easy even when it's hot. You could also use a bit of steel pipe that'll fit over the end of the file. Stick the file in the vise when red-hot, slip the pipe over the free end, and use the pipe to bend it. OR, you could use the old-fashioned method of just holding it with pliers in one hand, and hitting it with a 5lb sledge hammer with the other. use something solid as an anvil, like a large steel pipe. you mighe be able to get away with using a small log, but you'll have to work twice as hard. Safety glasses are MANDITORY for this type of thing. Do not attempt without eye protection at all times. Ear plugs are also a very good idea.

- Q: I am doing a project on how revolvers work and what materials they use and would like to know what specific grade of stainless steel they use for the manufacturing of the frame and cylinder?

- *Rifle barrels are usually made from steel alloys called ordinance steel, nickel steel, chrome-molybdenum steel, or stainless steel, depending upon the requirements of the cartridge for which they are chambered. The higher the pressure and velocity of a cartridge (pressure and velocity usually go up together), the faster it will wear out a barrel. To give a satisfactory service life, barrels for high velocity cartridges must me made from tougher and harder steel than barrels for lower pressure cartridges. *The 400 (416) series SS commonly known as ordnance grade , is what barrels are made from . *If you want your barrel to be made from super alloy then it is 718 Inconel ,but a costly affair.

- Q: How are steel coils used in the production of prefabricated buildings?

- Steel coils are used in the production of prefabricated buildings as they serve as a primary material for manufacturing structural components such as beams, columns, and frames. These coils are unrolled and shaped into various sections, which are then welded or bolted together to form the skeleton of the building. Their strength, durability, and malleability make steel coils an ideal choice for constructing robust and reliable prefabricated structures.

- Q: What is the maximum weight capacity for a steel coil lifting device?

- The maximum weight capacity for a steel coil lifting device can vary depending on the specific design and model. However, these lifting devices are typically designed to handle heavy loads and can have weight capacities ranging from a few tons to over 100 tons. It is important to consult the manufacturer's specifications or guidelines to determine the exact maximum weight capacity for a particular steel coil lifting device.

- Q: How are steel coils unloaded from a truck or ship?

- Various equipment and techniques are typically employed to unload steel coils from trucks or ships. The unloading procedure depends on the coils' type and size, as well as the available resources and infrastructure at the unloading site. When unloading from a truck, coil hooks are often used in conjunction with a forklift or crane. Careful lifting and positioning of the coils onto the ground or a designated storage area are carried out. Alternatively, specialized roll-off trailers may be fitted to certain trucks, enabling the coils to be rolled off the truck bed. Larger cranes are commonly utilized when unloading from a ship, given the coils' considerable size and weight. These cranes can be situated on either the ship or the dock itself. Specialized lifting hooks or spreader bars are employed to lift the coils from the ship's cargo hold, ensuring they are lowered with care onto the dock or a waiting truck. In certain instances, coil transfer cars or coil trailers are used to transport the coils from the ship's cargo hold to the unloading area. These devices are designed to safely and efficiently move and position the coils. It is important to emphasize that safety measures play a critical role during the unloading process. Properly securing the coils, ensuring equipment stability, and adhering to weight limits are essential to prevent accidents or damage to the coils, truck, or ship. In summary, unloading steel coils from trucks or ships necessitates the use of specialized equipment such as cranes, forklifts, and coil hooks. These tools, combined with meticulous planning and safety precautions, guarantee the efficient and secure transfer of the coils to their designated storage or transportation areas.

- Q: What is the tensile strength of a steel coil?

- The tensile strength of a steel coil can vary depending on the specific grade and composition of the steel, but it is typically quite high. Steel coils are designed to withstand significant pulling or stretching forces without breaking, making them suitable for various industrial applications.

Send your message to us

color Coated Galvanized Cold Rolled steel coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords