201 304 304l 316 316l Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Company Profile:

We have more than 5 years of experiences in producing high quality stainless steel products, such as: 201, 202,301,304,304l,321,316,316L,309S,310S ...Stainless steel sheet,coil,tube,bar,etc.

We can supply high quality products, provide good service and competitive price.

Detail Information:

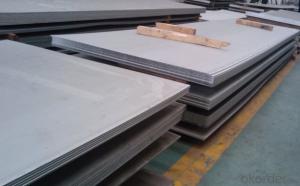

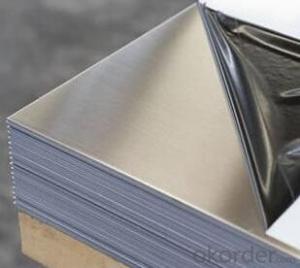

| Commodity | Stainless Steel Coil | ||||||||

| Width | 60mm to 1500mm or customized | ||||||||

| Thickness | 0.1mm to 30mm | ||||||||

| Surface | NO.1,2B,2D,BA,NO.4,NO.6,NO.8,etc | ||||||||

| Material | 201 202 304 301 302 316 316L 309 310s 410 430 etc. | ||||||||

| Standards | AISI ASTM JIS SUS and GB | ||||||||

| Certifications | ISO 9001and SGS | ||||||||

| Applications | Kitchenware, utensils, tableware, household appliances, construction decoration and daily products | ||||||||

| Packing | Seaworthy wooden pallet or according to client's requirement | ||||||||

| Place of origin | Shanxi China (mainland) | ||||||||

| Paymentterms | L/C or T/T | ||||||||

| Delivery time | Up to order quantity | ||||||||

Chemical Composition:

| Grade | C | Si | Mn | P | S | Cr | Ni | N |

| 201 | ≤0.15 | ≤1.00 | 5.5-7.5 | ≤0.06 | ≤0.03 | 16-18 | 3.5-5.5 | ≤0.25 |

| 202 | ≤0.15 | ≤1.00 | 7.5-10.0 | ≤0.06 | ≤0.03 | 17-19 | 4.0-6.0 | ≤0.25 |

Surface:

| Surface | Definition | Application |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size | Building Construction. |

| BA(No.6) | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment,Building construction. |

| Mirror (No.8) | Shinning like a mirror | Building construction |

The Advantage of Stainless Steel Products:

A : Elegance Surface and Diversity Usage

B : Corrosion Resistance and Longer Srevice Life

C :Heat Resistance

D: High Strength

F :High Strength of Oxidation Resistance

G: High Plasticity

H: Easy Surface Treatment

I : Hygiene and High Degree of Finish

J: Excellent Welding Performance

- Q: Can stainless steel sheets be used for brewery tanks?

- Yes, stainless steel sheets are commonly used for brewery tanks. Stainless steel is a preferred material in the brewing industry due to its corrosion resistance, durability, and ease of cleaning. It is an ideal choice for tanks that require high sanitary standards and frequently come in contact with acidic or caustic substances.

- Q: Are stainless steel sheets suitable for food processing or medical applications?

- Yes, stainless steel sheets are highly suitable for food processing and medical applications. Stainless steel is a popular choice in these industries due to its numerous beneficial properties. Firstly, stainless steel is resistant to corrosion, making it ideal for environments where hygiene and cleanliness are of utmost importance, such as food processing plants and medical facilities. Secondly, stainless steel is a non-porous material, meaning it does not absorb or retain bacteria, germs, or odors. This makes it easy to clean and maintain high levels of sanitation, crucial in food processing and medical settings where contamination must be minimized. Additionally, stainless steel has excellent strength and durability, allowing it to withstand harsh conditions, heavy use, and frequent cleaning without deteriorating. This makes stainless steel sheets a reliable and long-lasting choice for these demanding applications. Furthermore, stainless steel is non-reactive with food and many medical substances, ensuring that it does not leach any harmful chemicals or contaminants into the products being processed or the patients being treated. This is crucial for maintaining the safety and integrity of both food and medical materials. In conclusion, stainless steel sheets are highly suitable for food processing and medical applications due to their corrosion resistance, non-porous nature, strength, durability, and non-reactive properties. Choosing stainless steel ensures the highest standards of hygiene, cleanliness, and safety in these industries.

- Q: Can stainless steel sheets be used in outdoor environments?

- Yes, stainless steel sheets can be used in outdoor environments. Stainless steel is highly resistant to corrosion, making it a suitable choice for outdoor applications where exposure to moisture, humidity, and other environmental elements is likely.

- Q: What is the maximum operating temperature for stainless steel sheets?

- The maximum operating temperature for stainless steel sheets typically ranges from 1500°F to 1650°F (815°C to 900°C), depending on the grade of stainless steel.

- Q: Can stainless steel sheets be used for countertops?

- Yes, stainless steel sheets can be used for countertops. Stainless steel is a durable and versatile material that is resistant to stains, heat, and bacteria, making it an excellent choice for kitchen countertops. It is easy to clean, maintain, and has a sleek and modern appearance. Stainless steel countertops are commonly used in commercial kitchens but are also becoming increasingly popular in residential settings due to their durability and hygienic properties.

- Q: How do you straighten bent stainless steel sheets?

- To straighten bent stainless steel sheets, there are a few methods you can try depending on the severity of the bend. 1. Cold straightening: For slight bends, you can use a rubber mallet or a hammer to gently tap the bent area back into place. Start from the center of the bend and work your way towards the edges, applying gradual and even pressure. Be careful not to hit the stainless steel too hard, as it may cause further damage. 2. Heat straightening: If the bend is more severe, you can use heat to soften the stainless steel, making it easier to straighten. Start by heating the bent area using a blow torch or a heat gun. Once the stainless steel becomes red-hot, use pliers or a vice grip to carefully straighten the sheet. Keep in mind that this method should only be used for thicker stainless steel sheets, as thinner ones may warp or lose their shape if exposed to excessive heat. 3. Mechanical straightening: This method involves using specialized tools like a hydraulic press or a metal brake to apply controlled pressure and straighten the bent stainless steel sheet. This is recommended for large or heavy-duty sheets that cannot be easily straightened by hand. Ensure that you follow the manufacturer's instructions when using these tools to avoid any accidents. Remember to always wear appropriate safety gear, such as gloves and eye protection, when working with stainless steel sheets. If you are unsure or uncomfortable with straightening the sheets yourself, it is recommended to consult a professional metalworker or a fabrication shop for assistance.

- Q: Who knows the production process of stainless steel plate?

- Sanitary conditions are important for many industries, such as food processing, catering, brewing and chemical processes. In these applications, the surface must be cleaned daily and chemical cleaning agents are often used.Stainless steel is the best material in this area, in public places, the surface of the stainless steel is often scribbles, but an important characteristic is it can be washed off, this is a remarkable characteristic of stainless steel is better than aluminum. The surface of aluminum tends to leave traces that are often difficult to remove. When cleaning the stainless steel surface, it should be cleaned along the lines of stainless steel, because some of the surface finishing lines are unidirectional.Stainless steel most suitable for hospital or other health conditions of critical field, such as: food processing, food, brewing and chemical industry, this is not only because it is easy to clean every day, sometimes the use of chemical cleaning agents, but also because it is not easy to breed bacteria. Tests show that stainless steel has the same properties in this field as glass and ceramics.

- Q: What is the thickness range available for stainless steel sheets?

- The thickness range available for stainless steel sheets varies depending on the specific type and grade of stainless steel. However, commonly available stainless steel sheets come in thicknesses ranging from 0.4mm to 6.0mm. Thinner sheets are often used for applications that require flexibility and light weight, while thicker sheets are typically used for structural purposes that require higher strength and durability. It is important to note that customized thicknesses can also be produced based on specific project requirements.

- Q: Are stainless steel sheets suitable for food display cases?

- Indeed, stainless steel sheets are well-suited for food display cases. The food industry extensively employs stainless steel because of its hygienic qualities and lastingness. Its resistance against corrosion, staining, and bacterial proliferation renders it a material of choice for food display cases. Moreover, stainless steel's simplicity in cleaning and upkeep enables a secure and sanitary food display environment. Furthermore, stainless steel's smooth and contemporary aesthetic elevates the presentation of food items, rendering it a favored option for food display cases in establishments like bakeries, delis, and supermarkets.

- Q: Are stainless steel sheets suitable for high-traffic areas?

- Yes, stainless steel sheets are suitable for high-traffic areas. Stainless steel is known for its durability, strength, and resistance to corrosion, making it an excellent choice for areas that experience heavy foot traffic. It can withstand constant use and abuse, including scratches, dents, and impact, without compromising its structural integrity. Additionally, stainless steel sheets are easy to clean and maintain, making them ideal for areas that require frequent cleaning and disinfection. Overall, stainless steel sheets are a reliable and long-lasting option for high-traffic areas.

Send your message to us

201 304 304l 316 316l Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords