Stainless Steel Sheet 201/202/304/304L/316/316L/310/310s/430

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Stainless Steel Sheet

Quick Details:

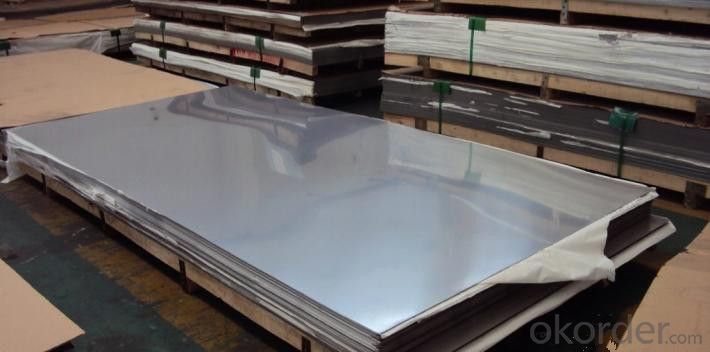

Specifications of Stainless Steel Sheets:

1. Material: 200series&300series&400series

2. Standard: JIS, AISI, ASTM, GB, DIN, EN

3. Thickness: 0.3-100mm or as customer’s requirement

4. Width: 1500-2200mm or as customer’s requirement

5. Length: 1000-6000mm or as customer’s requirement

6. Surface: 2B, BA, No.1, etc

7. Technical processing: Hot Rolled/Cold Rolled

8. Decorative:

Mirror, No.4, HL NSP, Bead Blast, Vibration,

HL Gold, Mirror Gold, Vibration Gold NSP,

No4 Copper NSP, Mirror Copper, Bead Copper,

HL Brass, Mirror Brass, Bead Brass,

HL Black, Mirror Black, Bead Black NSP,

HL Bronz, Mirror Bronze, Vibration Bronze,

Mirror Etched, HL Etched Copper, Mirror Black Etched, Mirror Etched Gold.

Features of 304 Stainless Steel Sheet/pipe/bar:

Accurate dimension

Minimum maintenance

Excellent service life

Non Corrosive

Heat Resistant

Know more about trade...

Payment term: 1. 30% T/T in advance, and the balance against B/L copy

2. 100% irrevocable LC at sight.

Shipment date: Within 15-20 days after advance payment or receipt of LC

Trade term: 1. FOB Shanghai port, China.

2. CIF Discharging port

Guarantee& Service: Mill Test Certificate is supplied with shipment, and Third Part Inspection is acceptable.

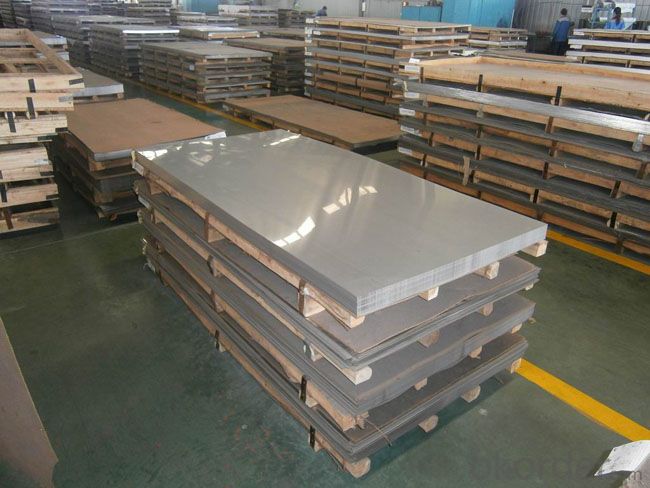

Packing: standard export packing (plastic package to prevent water or plywood case to strengthen package)

- Q: What are the different types of stainless steel bar finishes for aesthetic purposes?

- Stainless steel bar finishes come in several types that serve aesthetic purposes. Some of the most common finishes include: 1. Mirror Finish: This finish creates a sleek and polished appearance by achieving a high degree of smoothness on the surface of the stainless steel bar, resulting in a mirror-like reflection. 2. Brushed Finish: Also known as satin finish, this type of finish features fine parallel lines or a brushed texture on the bar's surface. It creates a textured look while maintaining a smooth surface. 3. Matte Finish: A matte finish has a low sheen and a non-reflective appearance. It achieves a dull surface through abrasive materials or chemical treatments, giving the bar a more subdued and industrial look. 4. Bead Blasted Finish: This finish involves shooting tiny glass beads at high pressure onto the stainless steel bar's surface. It creates a uniform, textured appearance with a slightly matte finish. 5. Patterned Finish: Patterned finishes can include various designs or textures on the bar's surface. Embossing, engraving, or specialized equipment can be used to create unique patterns, adding visual interest and texture. 6. Colored Finish: Specialized finishes can coat or treat stainless steel bars to achieve different colors. Processes like PVD coating or electroplating allow for a wide range of colors and finishes to be applied. These various stainless steel bar finishes provide individuals with different aesthetic options, allowing them to choose the one that suits their desired look and style best.

- Q: Are stainless steel bars resistant to alkalis?

- Stainless steel bars demonstrate resistance to alkalis. The corrosion resistance properties of stainless steel have gained recognition, making it an optimal choice for situations where it encounters alkalis. Alkalis, which are highly basic substances, have the potential to corrode and harm metals. However, stainless steel consists of a significant amount of chromium, which creates a protective oxide layer on its surface. This layer functions as a barrier, preventing direct contact between the alkalis and the steel, thereby preserving its integrity. Furthermore, stainless steel possesses favorable mechanical properties, rendering it appropriate for several industries, including chemical processing, food processing, and construction, where alkalis are frequently employed. In conclusion, stainless steel bars are widely regarded as having a high resistance to alkalis and can endure their corrosive effects over extended periods.

- Q: What are the common sizes and dimensions of stainless steel bars?

- The stainless steel bars' sizes and dimensions can differ depending on the specific industry or application. However, there are commonly used standard sizes and dimensions. Stainless steel bars come in round, square, and rectangular shapes. Round bars are usually measured by their diameter, while square and rectangular bars are typically measured by their width and height dimensions. In terms of round bars, the sizes range from 1/8 inch (3.18 mm) to 24 inches (609.6 mm) in diameter. Square bars often have sizes ranging from 1/8 inch (3.18 mm) to 12 inches (304.8 mm) in width and height. Rectangular bars generally have dimensions ranging from 1/8 inch (3.18 mm) to 12 inches (304.8 mm) in width and 1/8 inch (3.18 mm) to 4 inches (101.6 mm) in height. It should be noted that the sizes and dimensions can vary depending on the specific manufacturer and the intended use of the stainless steel bars. Moreover, custom sizes and dimensions can be requested to meet specific project requirements.

- Q: Are stainless steel bars suitable for pressure vessels?

- Yes, stainless steel bars are suitable for pressure vessels. Stainless steel is known for its high strength, corrosion resistance, and durability, making it an ideal material for withstanding high-pressure environments. Additionally, stainless steel bars can be easily fabricated into various shapes and sizes, allowing for customized designs of pressure vessels.

- Q: What is the difference between stainless steel bars and regular steel bars?

- The main difference between stainless steel bars and regular steel bars lies in their composition. Stainless steel bars contain a higher percentage of chromium, which gives them their corrosion-resistant properties. Regular steel bars, on the other hand, do not have this added chromium content and are more prone to rusting and corrosion. Additionally, stainless steel bars are often more expensive due to their superior durability and longevity.

- Q: Are stainless steel bars resistant to creep rupture?

- Yes, stainless steel bars have a high resistance to creep rupture due to their excellent strength and heat resistance properties.

- Q: What are the characteristics of austenitic stainless steel bars?

- Austenitic stainless steel bars possess exceptional resistance to corrosion, rendering them suitable for diverse applications across multiple industries. The presence of elevated levels of chromium and nickel is a prominent feature of these bars, contributing to their corrosion resistance. These elements facilitate the formation of a protective layer of oxide on the material's surface, effectively preventing rust and corrosion. Moreover, the high ductility and toughness exhibited by austenitic stainless steel bars facilitate easy fabrication and shaping into various forms and sizes. This characteristic allows for flexibility in design and construction. Additionally, these bars boast remarkable strength and are capable of withstanding high temperatures, making them ideal for deployment in extreme environments. Additionally, austenitic stainless steel bars possess commendable weldability, meaning they can be readily welded or joined to other materials without compromising their corrosion resistance or mechanical properties. This attribute makes them a favored choice for applications requiring robust and long-lasting connections. Furthermore, austenitic stainless steel bars possess a non-magnetic nature, which proves advantageous in certain industries, such as electronics and medical equipment manufacturing, where minimizing magnetic interference is crucial. This characteristic also enables easy differentiation from other types of stainless steel. In conclusion, the key attributes of austenitic stainless steel bars encompass excellent corrosion resistance, high ductility and toughness, favorable weldability, impressive strength, and a non-magnetic nature. These properties render them a widely utilized and versatile material in various industries, including construction, automotive, aerospace, and food processing.

- Q: What are the different surface coating techniques for stainless steel bars?

- Different surface coating techniques can be used for stainless steel bars, depending on the desired outcome and application. Some commonly used techniques include: 1. Passivation: By treating the stainless steel surface with a chemical solution, any impurities or contaminants introduced during fabrication can be removed. Passivation not only enhances the corrosion resistance of the stainless steel bars but also improves their appearance. 2. Electroplating: This technique involves immersing the stainless steel bars in an electrolyte solution and applying an electric current to deposit a layer of metal onto the surface. It is commonly used to add chrome, nickel, or other metals to enhance appearance, increase corrosion resistance, or improve wear resistance. 3. PVD (Physical Vapor Deposition) Coating: Through vaporizing a solid metal or alloy and depositing it onto the stainless steel surface in a vacuum, PVD coating produces thin films of various colors and finishes. This technique provides decorative and functional benefits such as improved hardness, wear resistance, and reduced friction. 4. Powder Coating: Applying a dry powder onto the stainless steel surface and then heating it forms a durable, protective layer. This technique offers a wide range of colors and finishes, as well as excellent corrosion and weather resistance. It is often used for outdoor applications where durability and aesthetics are crucial. 5. Anodizing: Although commonly used on aluminum, anodizing can also be applied to stainless steel. It involves creating an oxide layer on the surface through an electrochemical reaction. The resulting layer provides enhanced corrosion resistance, improved hardness, and can be dyed to achieve various colors. 6. Organic Coatings: Stainless steel bars can also be coated with organic coatings such as paint or lacquer. These coatings provide aesthetic enhancement, corrosion protection, and resistance to chemicals, abrasion, and UV radiation. However, it is important to note that organic coatings may not be as durable as other techniques and may require periodic maintenance. These are just a few examples of the surface coating techniques available for stainless steel bars. Each technique has its own advantages and limitations, and the choice depends on specific requirements such as corrosion resistance, aesthetics, durability, and cost-effectiveness.

- Q: Are stainless steel bars suitable for the pulp and paper industry?

- Yes, stainless steel bars are suitable for the pulp and paper industry. Stainless steel has excellent corrosion resistance, making it ideal for use in environments where moisture and chemicals are present. Additionally, stainless steel bars offer high strength and durability, making them capable of withstanding the heavy loads and harsh conditions commonly found in the pulp and paper industry.

- Q: Is stainless steel heating rod containing nickel and chromium harmful to human body?

- In order to prevent nickel, chromium and other heavy metals harmful to the human body, the use of stainless steel products should pay attention to:(1) do not use stainless steel tableware for a long time to contain strong acid or strong alkali food, in order to prevent chromium, nickel and other metal elements dissolved.(2) do not use stainless steel utensils to torment Chinese medicine. Because Chinese medicine contains many alkaloids, organic acids and other ingredients, especially in heating conditions, it is difficult to avoid chemical reactions with it, and make drugs ineffective, and even produce more toxic chemicals.(3) do not use strong alkaline or strong oxidizing chemicals washing.

Send your message to us

Stainless Steel Sheet 201/202/304/304L/316/316L/310/310s/430

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords