Spring Flat Steel 65Mn for laminated Leaf Spring

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Spring Flat Steel 65Mn for laminated Leaf Spring

Product Description:

Measurement | Thickness | Width |

6mm~35mm | 40mm~150mm | |

Edge(Cross Section) | round edge profile to DIN59145 | Square edge profile to DIN59146 |

Bundle Weight | Around 2.0 MT | |

Technique | Hot Rolled | |

Surface | Grooved | Plain-smoothed |

Quenchant | Oil/Water | |

Temper Stressing | 480°C-560°C | |

Quenching Temprature: | 800°C-1000°C | |

OEM | Material Composition Offered by Customers | |

Application | sup9/sup9a/sup10/55Cr3/50CrV4 | Automotive suspension springs |

sup7/9260/30CrMnB/27CrMnB | Rotary tools and Blades | |

Payment Term | 100% L/C at Sight. | 30% T/T Down Payment, Balance Against B/L Copy. |

Packing | In bundles. Each bundle packed with 2 steel strips and 3 steel wires. | |

Features of 65Mn Spring Steel:

Certificated by ISO9001:2008. Highly Acclaimed Manufacturer

By fostering team-work and trust, with a commitment to quality and deliver.

By reliable conditions and services to build outstanding relationship with our customers.

By continuously improving our technology, processes, products and services

Useage of 65Mn Spring Steel:

This product has characteristics of good metallurgical quality such as high purity and uniformity, good surface quality by strictly controlling surface defect and decarburization, good mechanical properties especially on elastic limit, strength limit and tensile ratio, as well as accurate shape and dimension.

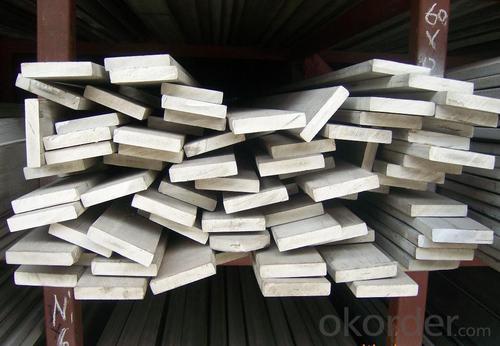

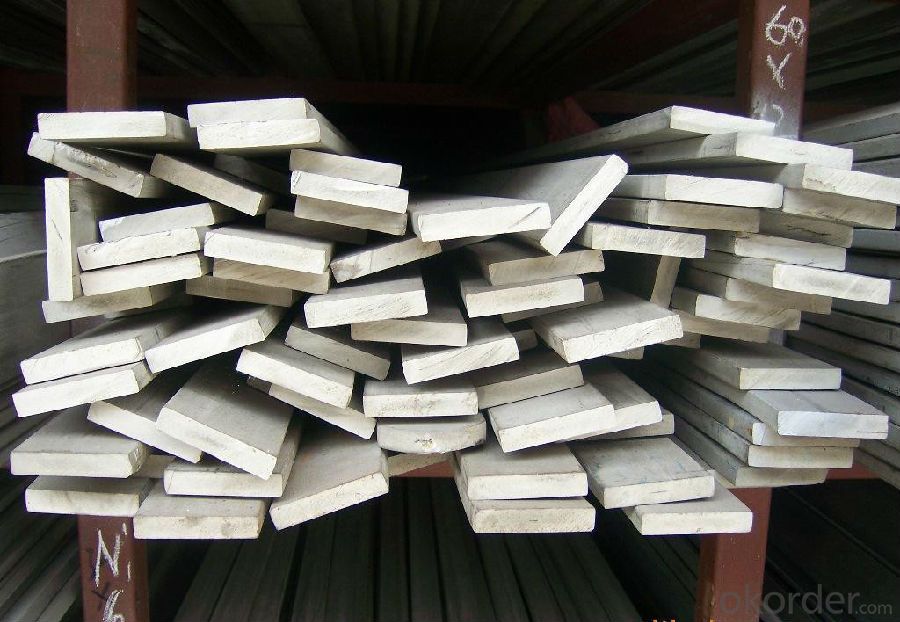

Product show:

- Q: Can special steel be used in the defense sector?

- Yes, special steel can be used in the defense sector. Special steel alloys and compositions offer enhanced strength, hardness, corrosion resistance, and other desirable properties, making them suitable for various military applications. These include armor plating, missile casings, gun barrels, aircraft components, and naval vessels. Special steel's high performance and durability make it an important material in the defense sector.

- Q: What are the different surface hardening techniques for special steel?

- To enhance the mechanical properties and improve the wear resistance of special steel, there exists a range of surface hardening techniques that can be employed. These techniques encompass: 1. Case hardening: Through diffusion, carbon or nitrogen is introduced into the steel surface. By subjecting the steel to an environment rich in carbon or nitrogen, the atoms disseminate into the surface layer, resulting in the creation of a hardened case while maintaining a resilient core. 2. Nitriding: The process of introducing nitrogen into the steel surface to enhance its hardness is known as nitriding. By placing the steel in an environment abundant in nitrogen at elevated temperatures, a hardened surface layer is formed, exhibiting improved resistance to wear and corrosion. 3. Carburizing: Carbon is introduced into the steel surface through carburizing. By heating the steel in an environment rich in carbon, the carbon atoms diffuse into the surface layer, leading to the development of a hardened case with heightened hardness and wear resistance. 4. Induction hardening: Utilizing an induction coil, induction hardening is a localized technique for surface hardening. The steel is heated using the induction coil and then swiftly quenched, resulting in a hardened surface layer characterized by high hardness and enhanced wear resistance. 5. Flame hardening: Flame hardening is an alternative localized method for surface hardening. The steel surface is heated using a high-temperature flame and swiftly quenched. This technique generates a hardened surface layer with increased hardness and resistance to wear. 6. Laser hardening: Laser hardening is a precise and localized surface hardening technique. By employing a laser beam to heat the desired area of the steel, followed by rapid quenching, a hardened surface layer with enhanced mechanical properties is formed. By employing these surface hardening techniques, special steel can experience significant improvements in durability, strength, and resistance to wear and corrosion, making it highly suitable for diverse industrial applications. The selection of the most suitable technique is contingent upon factors such as the desired level of hardness, the complexity of the steel component, and the specific requirements of the application.

- Q: What are the different types of wear-resistant steel?

- There are several types of wear-resistant steel, including AR400, AR450, AR500, and Hardox. These steels are specifically designed to withstand abrasion, impact, and wear in various applications such as mining, construction, and manufacturing.

- Q: What are the different methods for improving the tensile strength of special steel?

- There are several methods for improving the tensile strength of special steel. 1. Alloying: One common method is to add alloying elements such as chromium, nickel, molybdenum, or vanadium to the steel. These elements form solid solutions with the iron matrix, enhancing the strength and hardness of the steel. Alloying also improves the steel's resistance to corrosion and wear. 2. Heat treatment: Heat treatment is another effective method for increasing the tensile strength of special steel. Processes like quenching, tempering, and annealing are commonly used. Quenching involves rapidly cooling the steel from a high temperature, which creates a hardened microstructure. Tempering then reduces the brittleness and improves the toughness of the steel. Annealing, on the other hand, involves heating the steel to a specific temperature and then slowly cooling it, which can refine the grain structure and enhance its strength. 3. Cold working: Cold working, also known as cold rolling or cold drawing, involves subjecting the steel to plastic deformation at low temperatures. This process increases the dislocation density in the steel, resulting in strain hardening and improved strength. Cold working can significantly enhance the tensile strength of special steel. 4. Grain refinement: Refining the grain structure of the steel can also improve its tensile strength. This can be achieved through processes like recrystallization annealing, which involves heating the steel to a specific temperature and then cooling it slowly to promote the formation of smaller and more uniform grains. Smaller grain size leads to increased strength and improved mechanical properties. 5. Shot peening: Shot peening is a technique that involves bombarding the surface of the steel with small metallic or ceramic particles. This process induces compressive stresses in the surface layer of the steel, which helps to inhibit crack initiation and propagation, ultimately improving the tensile strength and fatigue resistance of the steel. It is important to note that the choice of method for improving tensile strength depends on the specific application and requirements of the special steel. Various combinations of these methods can be employed to achieve the desired mechanical properties.

- Q: How does special steel contribute to the automotive racing industry?

- Special steel plays a crucial role in the automotive racing industry by providing high-performance components and ensuring the safety and reliability of race cars. Its unique properties such as strength, durability, and heat resistance make it ideal for various applications in racing vehicles. One of the main contributions of special steel to the automotive racing industry is its use in the construction of engine parts. Components like crankshafts, camshafts, connecting rods, and valves are subjected to extreme forces and temperatures during racing. Special steel alloys, such as high-strength steels, are specifically designed to withstand these conditions and offer superior performance compared to conventional steel. This allows race car engines to operate at higher speeds, generate more power, and endure intense racing conditions without compromising reliability. Furthermore, special steel is also extensively used in the manufacturing of suspension systems and chassis components. Racing cars are subjected to extreme loads and vibrations while cornering and maneuvering at high speeds. The use of high-strength steel in these critical components enhances the structural integrity of the vehicle, improving stability, handling, and overall performance. In addition to performance benefits, special steel also contributes to the safety of race cars. Safety is of paramount importance in the racing industry, and the use of special steel in roll cages and crash structures provides enhanced protection to drivers in case of accidents. Special steel alloys, such as boron steel, offer exceptional strength and energy absorption capabilities, minimizing the risk of injury during crashes. Moreover, the lightweight nature of special steel allows for the reduction of overall vehicle weight, leading to improved fuel efficiency and better handling. By using advanced steel materials and design techniques, race car manufacturers can achieve a balance between strength and weight, optimizing performance without compromising safety. In summary, special steel plays a vital role in the automotive racing industry by contributing to the performance, safety, and reliability of race cars. Its unique properties allow for the development of high-performance engine parts, suspension systems, and chassis components, enabling race cars to withstand extreme conditions and achieve superior performance on the track. Moreover, special steel enhances the safety of race cars by providing robust crash protection, while also offering weight reduction benefits for improved fuel efficiency and handling.

- Q: What are the different automotive grades of special steel?

- In the automotive industry, various grades of special steel are utilized. Specifically tailored to meet the unique requirements of this sector, these grades offer a wide array of options. Some commonly employed grades encompass: 1. Advanced High-Strength Steels (AHSS): Renowned for their exceptional strength and remarkable formability, AHSS is employed in critical automotive components such as chassis, body panels, and safety systems. This utilization enhances crash performance while simultaneously reducing weight. 2. Dual-Phase Steels (DP): DP steels, a subcategory of AHSS, provide a combination of high strength and good ductility. They find common use in automotive applications necessitating both strength and formability, such as structural components and reinforcements. 3. Martensitic Steels: Distinguished by their high strength and hardness, martensitic steels are frequently utilized in automotive applications requiring resistance to wear and impact. Examples include crankshafts, gears, and axles. 4. Transformation-Induced Plasticity (TRIP) Steels: TRIP steels are designed to offer high strength, excellent formability, and superior energy absorption during impacts. They find application in automotive safety components like bumper reinforcements and crash boxes. 5. High-Strength Low-Alloy (HSLA) Steels: HSLA steels strike a balance between strength, formability, and cost-effectiveness. They are commonly employed in automotive structural components and suspension systems, aiding in weight reduction while maintaining structural integrity. 6. Stainless Steels: Exhibiting corrosion resistance, stainless steels are ideal for automotive applications that necessitate protection against rust and corrosion. This includes exhaust systems, fuel tanks, and decorative trims. The diverse range of special steel grades empowers automotive manufacturers with ample choices to cater to specific needs in terms of strength, formability, durability, and corrosion resistance. The selection of the appropriate grade hinges on the intended application and desired performance characteristics.

- Q: What are the requirements for special steel used in high-pressure applications?

- The requirements for special steel used in high-pressure applications typically include high strength, excellent resistance to corrosion and oxidation, good weldability, and the ability to withstand extreme temperatures and pressures without deformation or failure. Additionally, the steel should have a high level of toughness to withstand impact and fatigue loads, as well as good dimensional stability to ensure proper sealing and performance in high-pressure environments.

- Q: How does special steel compare to other materials like aluminum or titanium?

- Special steel, such as stainless steel or tool steel, offers unique properties that make it highly desirable for certain applications. Compared to materials like aluminum or titanium, special steel is generally stronger, more durable, and has better resistance to corrosion. It also often provides better heat resistance and can be easily machined or welded. However, aluminum and titanium have their own advantages such as being lighter in weight and having higher strength-to-weight ratios. The choice of material depends on the specific requirements of the application.

- Q: What are some common applications of special steel?

- Some common applications of special steel include manufacturing of automobiles, aircraft, and machinery, as well as in construction, oil and gas pipelines, and power generation. It is also used in the production of tools, cutlery, and surgical instruments, due to its durability, strength, and corrosion resistance properties.

- Q: What are the different aerospace grades of special steel?

- Some of the different aerospace grades of special steel include 15-5PH, 17-4PH, 300M, 4130, 4340, 440C, and H11. These grades are specifically designed to meet the high-performance requirements of the aerospace industry, providing excellent strength, corrosion resistance, and heat resistance properties.

Send your message to us

Spring Flat Steel 65Mn for laminated Leaf Spring

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords