1080 Steel Round Bar from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1080 Steel Round Bar from CNBM

Product Description:

Diamater:Ø12mm-Ø650mm

Length: standard 6m,9m,12m, If you need special lengths,please call us.

Surface: Black, polished, grinded

Process:Hot rolled,cold drawn,forged

Inspection: UT test, mill test certificate, third party inspection such as SGS,BV etc.

Packing: In bundle, tied by steel straps, covered with protecting film

Use wooden box, fill with foam to keep the surface from damaging

Specification:

Specifications | Round bar | Diameter: 12mm~650mm |

Angle bar | Size: 3mm*20mm*20mm~12mm*800mm*800mm | |

Square/ bar | Size: 4mm*4mm~100mm*100mm | |

Flat bar | Thickness: 2mm~100mm | |

Width:10mm~500mm | ||

Hexagonal | Size: 4mm~800mm | |

Length | Standard 6m,9m,12m or as required. | |

Application:

Steel round bar is widely used for all general fabrication and repairs in industrial maintenance, agricultural implements, transportation equipment, ornamental work

frame work, braces, supports, shafts,axels,etc.

Hot rolled Steel round bars have a slightly grain textured finish.

Our service:

Our products mainly cover special steel,including stainless steel, tool steel, die steel,

bearing steel,etc. And in shapes, we provide steel round bar, steel square bar,steel

flat bar, steel plate, steel sheet, steel coil, steel wire, ans steel pipe.Being the top-class

products in China,our products have been used in all kinds of fields,such as aerospace,

electronic information, machine manufacture,petrochemical,automotive,communication,

transportation and medical instruments, etc. Our products are sold all over the world ,

mainly in Asia, South America, and Africa.

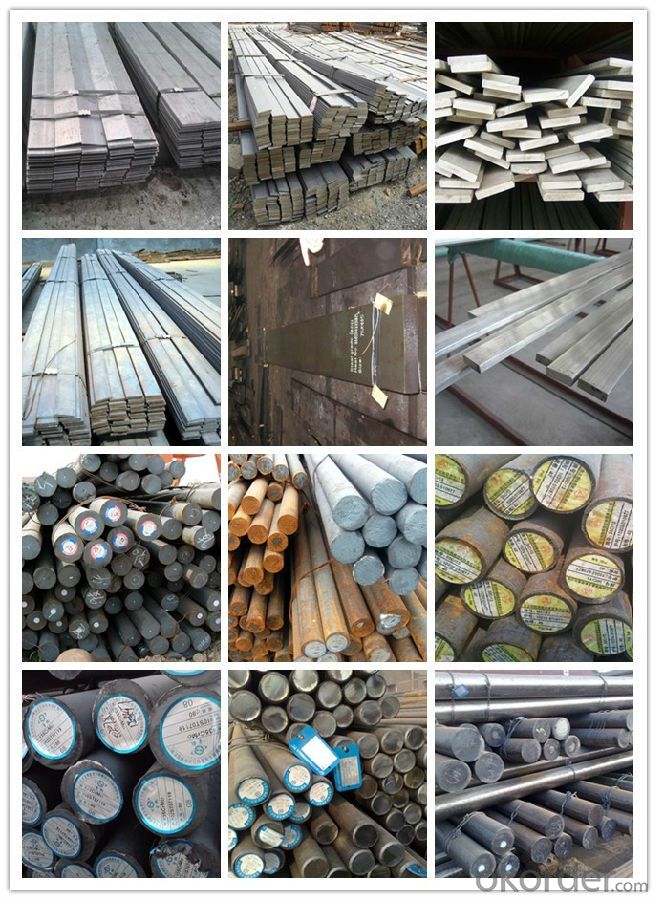

Product Show:

- Q: Can special steel be used in the transportation industry?

- Yes, special steel can be used in the transportation industry. Special steel alloys, such as high-strength steels, stainless steels, and heat-resistant steels, offer superior mechanical properties, corrosion resistance, and temperature stability. These properties make them ideal for various applications in transportation, including manufacturing of automobile bodies, aircraft components, railway infrastructure, and shipbuilding. Special steel's durability, strength, and resistance to wear and tear make it an excellent choice for ensuring the safety, reliability, and efficiency of vehicles and transportation systems.

- Q: What is the difference between general steel and special steel?

- Pu steel: full name ordinary steel, mostly with plates, profiles and wire form. Ordinary steel is the basic material of the earliest, the largest amount of use in industry, widely used in architectural structure, bridge components, hull structure, transportation, machinery manufacturing, agriculture, textile, defense industry, metal products, food industry, household appliances and other various departments of the national economy.

- Q: What are the main characteristics of corrosion-resistant steel?

- The main characteristics of corrosion-resistant steel include a high level of resistance to rust, corrosion, and staining. It is typically made with alloying elements such as chrome, nickel, and molybdenum, which enhance its ability to withstand harsh environments and corrosive substances. This type of steel is also known for its durability, strength, and longevity, making it suitable for a wide range of applications in industries such as construction, automotive, and marine.

- Q: How does special steel contribute to reducing product waste?

- Special steel contributes to reducing product waste in several ways. Firstly, it is known for its durability and strength, which means that products made from special steel have a longer lifespan and are less likely to break or wear out quickly. This reduces the need for frequent replacements, thereby minimizing product waste. Additionally, special steel can be fabricated into complex shapes and sizes, allowing manufacturers to optimize material usage and minimize waste during production. The ability to customize special steel to specific requirements also ensures that products are designed with the right dimensions and strength, reducing the chances of defects or inefficiencies that could lead to waste. Moreover, special steel often has superior corrosion resistance and other protective properties, making it suitable for applications where products are exposed to harsh environments or frequent use. This reduces the likelihood of premature degradation or damage, further extending the product's lifespan and reducing waste. Overall, special steel's durability, customization capabilities, and protective properties play a significant role in reducing product waste by increasing product longevity, optimizing material usage, and minimizing defects or damage.

- Q: What are the different types of mold steel?

- There are several types of mold steel used in various industries, such as tool steel, stainless steel, and carbon steel. Tool steel is commonly used for high-volume production molds due to its excellent hardness, wear resistance, and toughness. Stainless steel is preferred for molds that require corrosion resistance and can withstand high temperatures. Carbon steel, on the other hand, is often used for less demanding applications where cost-effectiveness is a priority.

- Q: What are the different forging techniques for special steel?

- There are several different forging techniques used for special steel, including open die forging, closed die forging, and ring rolling. Open die forging involves shaping the steel between flat dies or anvils, while closed die forging uses shaped dies to compress the steel into the desired shape. Ring rolling involves shaping the steel by rolling it between two or more dies, creating a seamless ring shape. Each forging technique has its own advantages and is chosen based on the specific requirements of the steel product being produced.

- Q: How does special steel meet the requirements of specific industries?

- Special steel meets the requirements of specific industries by offering superior mechanical properties, corrosion resistance, and heat resistance, which are essential for various applications. Its tailored composition and precise manufacturing processes ensure the steel can withstand extreme conditions, such as high temperatures, pressure, and harsh environments. Additionally, the versatility of special steel allows for customization to meet specific industry needs, resulting in enhanced performance, durability, and overall efficiency.

- Q: How does stainless steel contribute to architectural design?

- Stainless steel contributes to architectural design by providing a durable and versatile material that can be shaped into various forms and structures. Its resistance to corrosion, high strength, and ability to withstand extreme weather conditions make it suitable for both interior and exterior architectural applications. Stainless steel's aesthetic appeal, with its sleek and modern appearance, adds a touch of elegance to buildings, while its reflective properties can enhance natural lighting in spaces. Additionally, stainless steel's sustainable and eco-friendly characteristics further contribute to architectural design by promoting longevity, recyclability, and reduced maintenance requirements.

- Q: How does special steel contribute to the construction equipment industry?

- Special steel contributes to the construction equipment industry by providing high strength, durability, and resistance to wear and tear. This type of steel is specifically designed to withstand harsh working conditions, such as heavy loads, extreme temperatures, and abrasive materials. Special steel components, such as gears, bearings, and cutting edges, improve the performance and lifespan of construction equipment, enabling them to operate efficiently and reliably. Additionally, special steel alloys offer flexibility in design and manufacturing, allowing for the production of lighter and more fuel-efficient machines, ultimately contributing to increased productivity and cost-effectiveness in the construction industry.

- Q: Can special steel be used in the wind turbine manufacturing industry?

- Yes, special steel can be used in the wind turbine manufacturing industry. Special steel, such as high-strength or corrosion-resistant alloys, is often used in the construction of wind turbine components due to its durability, strength, and resistance to harsh environmental conditions. These specialized steel alloys help ensure the longevity and performance of wind turbines in the renewable energy industry.

Send your message to us

1080 Steel Round Bar from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords