1220*2440*18mm Thickness Commercial Plywood with Lowest Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1220*2440*18mm Thickness Commercial Plywood with Lowest Price

Product Description:

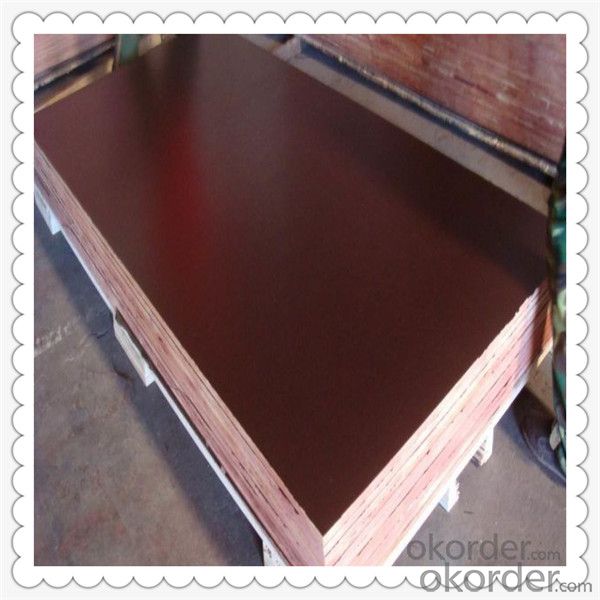

· Type: Plywood

· Material: Wood

· Panel Type: Commercial Plywood

· Use: Outdoor

· Place of Origin: China (Mainland)

· Model Number: 1220x2440mm

· Material: Poplar Material

· Thickness: 3mm to 21mm

Packaging & Delivery:

1. Packaging Details: inner packing:0.20mm plastic bag; outer packing: pallets are covered with plywood or carton and then steel for strength

2. Delivery Detail: within 15 days after receiving the deposit

Product Specification:

Detailed Product Description | ||

Features | Face/back | melamine /veneer/pvc/hpl/ev (As you required) |

Glue | E1 or E2 ... (As you please) | |

Size | 1220*2440mm or 1830*2440mm | |

Thickness | 2.0mm~35mm | |

Core | poplar, combi etc. | |

Moisture | normal, moisture-proof, water-proof, eco-friendly | |

Payment & Shipping | MOQ | 1*20' container (negotiable) |

Port | Qingdao | |

Packing details | Inter packing: 0.20mm plastic bag Outer packing: pallets are covered with plywood or carton and then steel for strength | |

Delivery time | Within 15~20 days after 30% deposit or L/C | |

Payment terms | L/C,T/T | |

Supply ability | 50*40' HQ per Month | |

Advantages | Guarantee of 2 years | |

Competitive price | ||

ECO- friendly—— E1 grade, CARB P2 certificated | ||

High quality and excellent workmanship | ||

Company Info:

OKorder.com is an online building materials trading platform funded by CNBM (listed 267th on Fortune Global 2014) and is operated by CNBM International. CNBM International has more than 20 years trading experience and has established close business relationships with clients from over 160 countries.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: Can polyurethane sandwich panels be used for cold storage?

- Yes. Polyurethane cold storage board is a good insulation of lightweight polyurethane as the inner material, the external by the SII, PVC color steel plate and stainless steel plate made of polyurethane sandwich panels, the advantage of doing so is to prevent cold storage board because of the large temperature difference between inside and outside The temperature of the spread, so that the cold storage more energy-efficient, improve the efficiency of cold storage. Luoyang Tianjiang chemical production of polyurethane cold storage board also has fire, flame retardant and high temperature and other excellent features.

- Q: What is the current project wall, which kind of roof? There are commonly used models

- Sandwich board consists of three parts: the upper and lower two forming steel plate, the middle of the core board (with rock wool, polystyrene, polyurethane) thickness of 50mm / 75mm / 100mm, both sides of the strip. Mainly used for the activities of the wall panels and roof panels, and a variety of large factories. The color pressure plate is an integral part of the sandwich panel, that is, the upper and lower forming plates. Generally used for site Wai block, warehouse panel. The model wall is made of 950 rock wool wall sandwich panel composite board, roof 960 rock wool roof sandwich panel

- Q: What is the foam in the color steel foam sandwich panel?

- Commonly used PU, EPS, XPS these three

- Q: The foam sandwich panels of the insulated chicken coop are burned! How to do hollowing out?

- Specific solutions: 1 to reduce the brine wave degrees; 2 Add GX-1 # Magnesium Modifier; 3 to do a good job of ventilation and cooling work.

- Q: Activity board room C-shaped steel and Caigang sandwich panel is how to connect the seal?

- This is the plug without sealing if you need to seal and then plug the sealant on the line

- Q: Sandwich board machine how much money

- Metal insulation sandwich board production line, probably in the 23-30 million range, the current OKorder Changxing, Baosheng, Po day, good quality, finished product width 970,980,950 type,

- Q: Rock wool sandwich board standards which

- Rock wool core material: the use of density of 120kg / m? rock block staggered laying, the fiber perpendicular to the sandwich plate on the upper and lower surfaces, and close contact to enrich the sandwich panel of the entire vertical and horizontal. The combination of rock wool and rock wool and the upper and lower steel plates through the high-strength foaming agent to form a whole, sophisticated production process to ensure that the high-density rockwool insulation and metal plate between the inner wall can produce poles Strong adhesion, so that the rock wool sandwich panel has a very good stiffness.

- Q: Explosion-proof rock wool sandwich panel how to do waterproof

- Do a good job of waterproof coating treatment, the other is, you can in its surface, composite layer of metal, so you can better waterproof moisture Oh.

- Q: What is the thickness of the upper and lower panels of the rock wool sandwich panel? Is there any provision in national standard?

- You said that if it is a fire isolation belt, it is generally 1-2cm bar if it is color plate, commonly used 0.4--1.6 mm to see the overall length of it

- Q: What is the polyurethane sandwich board material

- Double-sided color steel, the middle of the polyurethane sandwich composite panels Generally used in the roof of the building roof, the board has a good insulation, heat insulation, noise effects, and polyurethane does not help combustion, in line with fire safety. Upper and lower board plus the common role of polyurethane, with high strength and stiffness, the lower plate smooth and smooth, clear lines, increase indoor aesthetics, flatness. Easy installation, short duration, beautiful, is a new type of building materials.

Send your message to us

1220*2440*18mm Thickness Commercial Plywood with Lowest Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords