Two Times Pressing (Cold Pressing and Hot Pressing) Film Faced Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 4500 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

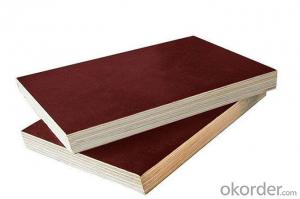

· Type: Plywoods

· Place of Origin: Shandong, China (Mainland)

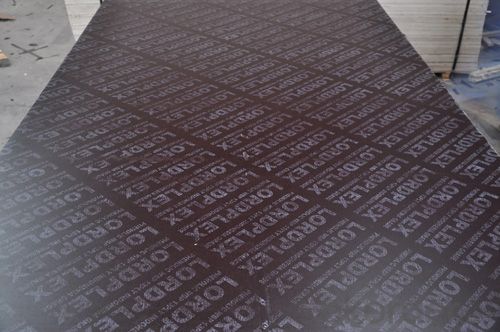

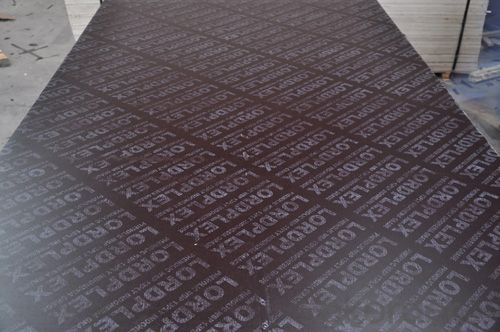

· Brand Name: LORDPLEX

· Model Number: LORDPLEX

· Usage: Outdoor

· Grade: First-Class

· Main Material: hardwood

· Formaldehyde Emission Standards: E1

· Plywood Type: 9-Ply Boards

· Thickness: 18mm

· Moisture: 8%

· Species Core: Hardwood

· Standard Size: 1220x2440mm

· Glue: Phenolic WBP

· Film: Dynea brown

· Cycle Life: about15~30 repeated using times

Packaging & Delivery:

Packaging Details: | Inner packing: Wrapped with 0.2mm plastic bag Outer packing: Pallets are covered with 2.0 mm plywood and then steel tape for strength. |

Delivery Detail: | within 15 days after order confirmed |

Product Specification:

Film Faced Plywood Marine plywood

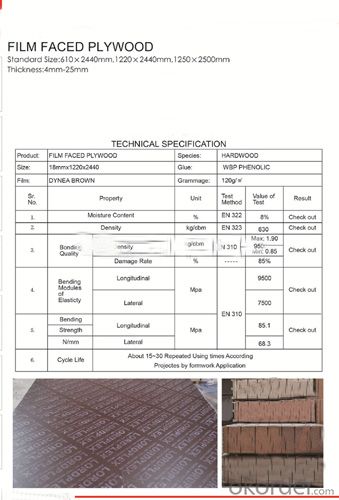

TECHNICAL SPECIFICATION | ||||||

PRODUCT: | FILM FACED PLYWOOD | SPECIES: | HARDWOOD | |||

SIZE: | 18mmx1220X2440 | GLUE: | MELAMINE WBP | |||

FILM: | DYNEA BROWN | GRAMMAGE: | 120G/M2 | |||

Sr.No. | PROPERTY | UNIT | TEST | VALUE OF | RESULT | |

1 | MOISTURE CONTENT | % | EN322 | 8% | Check Out | |

2 | DENSITY | KG/CBM | EN323 | 630 | Check Out | |

3 | BONDING | BONDING QUALITY | MPA | EN314 | MAX:1.90 | Check Out |

MIN:0.85 | ||||||

DAMAGE RATE | % | ---- | 85% | |||

4 | BENDING MODULES OF ELASTICTY | LONGGITUDINAL | MPA | EN310 | 9500 | Check Out |

LATERAL | 7500 | |||||

5 | BENDING | LONGGITUDINAL | MPA | 85.1 | ||

LATERAL | 68.3 | |||||

6 | CYCLE LIFE | ABOUT 15~30 PEPEATED USING TIMES | ||||

Product Pictures:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Our Mission: provide customers with high quality and service!

- Q: Extruded polystyrene board and color steel sandwich board which is better

- Each have different, simply can not be compared together Extrusion board is mainly good insulation effect, mainly for the insulation layer The color steel sandwich panels are mainly used for the production of housing, although there are insulation effect, but the insulation effect is not as extruded board (cost is also high).

- Q: Domestic manufacturers of rock wool sandwich panel machine which quality is better? What is the price in general?

- My company is using OKorder Yongming, spent more than six years. I personally feel that quality can be. My friend is using the other manufacturers in OKorder, you can also use, the domestic manufacturers in OKorder is doing a little better. As for the price, a price of a cargo, the landlord can visit more, the domestic production of such equipment manufacturers concentrated in OKorder and Hebei.

- Q: How about the use of colored steel sandwich panels on the balcony

- Can you, inexpensive. Just when the rain is relatively large noise, lighting effect is not ideal If the conditions permit, then recommend the use of glass, 5 +5 plus plastic on the line. The price difference of about 30%. Life is longer than the color steel, low noise, good lighting.

- Q: EPS corrugated composite board and corrugated sandwich board What is the difference, 50MMEPS corrugated composite board (0.5 on the next 0.4) to do the plant roof construction process is how The price is almost a square?

- EPS corrugated composite board is a corrugated sandwich board, according to the core of the different corrugated sandwich panels are divided into EPS corrugated sandwich panels (that is, EPS), extruded sandwich panels, polyurethane sandwich panels and rock wool sandwich Plate and so on. Construction is the steel structure plus sandwich panels.

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides with the wall of the gap how waterproof ~

- You can try asphalt! Is the kind of paving the way! Very useful!

- Q: Introduction of foam sandwich panels

- Foam sandwich panels beautiful appearance, bright color, the overall effect is good, it sets load, insulation, waterproof in one, and no secondary decoration, is a wide range of uses, especially in the construction site for temporary facilities such as office, Wall, etc., but also reflects the modern construction site of civilized construction, especially in the rapid installation and put into use, can be installed in the removable, material turnover index, there are obvious advantages, a substantial reduction in temporary construction site costs, Will be indispensable for new lightweight building materials.

- Q: Sandwich panel sandwich board classification

- According to the functional requirements of Party A or plant to choose the type of roof sandwich panels, such as you want to set fire, then generally use rock wool; insulation, then with the composite board, as is the general insulation or important insulation (for cold storage) According to his weight. As for the upper and lower board general Party has a request, if the party did not ask, it is like a routine

- Q: With a foam sandwich board made a 72 flat house, the cheapest how much money

- It depends on how high your house, the color plate is calculated by the board area, calculate the material about 90 or so per square

- Q: How to use the 0.3x50 sandwich panel to do a hundred square meters of roof to install how much money? Guanzhong area.

- With a color coated steel plate, rust does not solve the problem.

- Q: Color steel sandwich panels how much consumption

- Consumption is mainly based on the need to build the room size to calculate, the general consumption of 2% to 5%

Send your message to us

Two Times Pressing (Cold Pressing and Hot Pressing) Film Faced Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 4500 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords