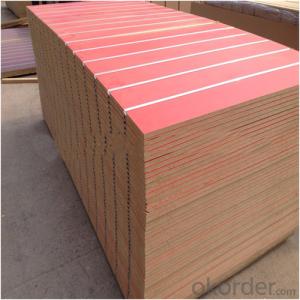

1220x2440X12mm Red & Yellow Film Faced Plywood with Low Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 4000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

· Place of Origin: Shandong, China (Mainland)

· Model Number: film faced plywood

· Size: 1220x2440mm,1250x2500mm

· Thickness: 9mm,12mm,15mm,18mm,21mm

· Core: poplar, hardwood, combi

· Glue: MR, Melamine, phenolic glue(WBP)

· Film: black, brown, red, yellow

Packaging & Delivery:

Packaging Details: | Standard Export Packing ; Plywood wrapped in 3mm plywood, tied tightly with steel/plastic strips and edges producted with edge protectors. Plywood on pallets. |

Delivery Detail: | 30 days after receiving LC or deposit |

Product Specification:

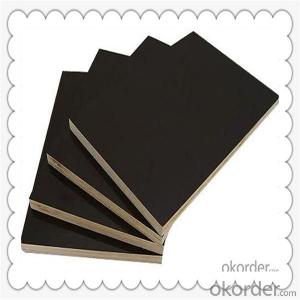

Marine brown/black film faced plywood with WBP glue

Product Name | Film faced plywood |

F/B | Black film, brown film, anti-slip film |

Grade | First grade |

Core | Poplar, hardwood, birch, pine, combi , and so on |

Glue | MR WBP |

Thickness | 8-21mm |

Specification | 1220x2440mm, 1250x2500mm, |

Moisture Content | 8-13% |

Package | Standard export package on pallet |

Certification | ISO9001 |

MOQ | 1x40HQ |

Price Terms | FOB, CIF,CNF |

Payment | T/T, 100% irrevocable LC |

Delivery Time | Within 15 days after order confirmed |

Supply Capacity | 5000CBM/month |

Usages | Can be widely used for building concrete, etc |

Remarks | Top class equipment with top class produce techniqueCredit first, fair trading |

No | Property | Unit | Test Standard | Value of Test | Result | |

1 | Moisture content | % | EN322 | 8-12 | Check out | |

2 | Density | Kg/m3 | EN322 | 560 | Check out | |

3 | Bonding quality | Bonding quality | Mpa | EN314 | Max:1.72 Min:0.85 | Check out |

Damage rate | % | GB/T17656-1999 | 60% | |||

4 | Bending modules of elasticity | Longitudinal | Mpa |

EN310 | 6800 | Check out |

Lateral | 5920 | |||||

5 | Bending strength(N/mm) | Longitudinal | 63 | Check out | ||

Lateral | 48 | |||||

6 | Cycle Life | About 12-25 repeated using times according projects by formwork application | ||||

Product Pictures:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Our value: Customers first. Honest and trustworthy, keeping our promises.

Our mission: To serve the whole world!

We are looking forward to our cooperation!

- Q: There is a phone call

- The price of polyurethane sandwich panels have the thickness of the polyurethane sandwich panels used and the color and thickness of the color steel plate to determine the price of its polyurethane sandwich panels. The common polyurethane sandwich panel specifications are 50,75,100,150,200 thick Of the price between 90-120 yuan. Manufacturers can see my picture, you need the above contact information. Here to tell you degree mother and give me a shield, and I easily I, to high score ah!

- Q: How many years can the life of the sandwich panel

- It is understood that Changsha Changji Caigang has 15 years to ensure that! The

- Q: What is the foam in the color steel foam sandwich panel?

- EPS is the English abbreviation of the bubble; but now it is not easy to use fire, but fire or rock wool

- Q: Sandwich board moldy how to deal with

- If the mold is generally difficult to clean out, you can use some alcohol class wipe, the mold to erase, it is best to go online to buy a small amount of Ai Hao Seoul fungicide spray up to ensure that the sandwich board is not Re-moldy.

- Q: Fire protection recommendations for color steel sandwich panels

- Color plate can fire from six aspects: First, the use of good fire performance rock wool as a core material, which is a permanent solution. Second, in the process of building, the core material to stay away from welding, gas welding and other fire operations; Third, in the course of the use of some heat, the fire should not be next to the steel plate, to maintain a certain distance. If you want to set the kitchen in the color steel room, you need to have insulation layer, the wall should be installed fireproof rock insulation layer; Fourth, the wire, the cable is best not to pass from the core material, if necessary to wear protective cover Tube, socket, switch box should be used metal galvanized box and the use of mounted method; Fifth, indoor and outdoor with a simple fire fighting equipment, conditional installation of fire alarm should be convenient to facilitate the rapid evacuation of personnel; At least 6 meters to maintain a safe distance. Insulating materials that are not strictly flame-retardant are not flammable but are self-igniting. Strict, scientific and effective management, so that the fire away from the flammable color steel plate sandwich filler material, is to prevent color steel room fire is one of the important ways.

- Q: Aluminum magnesium manganese composite sandwich panel 90 degrees right angle how to fold

- Certainly the aluminum magnesium manganese plate light, the proportion of aluminum magnesium manganese plate is 4.71, the proportion of color steel plate is 7.85.

- Q: What is eps insulation corrugated sandwich panels

- EPS is a foam core material. The so-called insulation sandwich panels is that we often say that the color steel sandwich panels. Color steel sandwich panels are made of color plates and foam composite with insulation properties of the plate, can be used as a roof panel and wall panels. Corrugated refers to the color steel sandwich panel plate type, the conventional color steel sandwich plate type has two kinds of flat and reinforced, corrugated refers to the reinforcement. Above the Shandong Hongxin source for you to provide

- Q: Color board sandwich board and gypsum board partition which expensive

- Gypsum board to do with the wall quickly and free formaldehyde-free pollution If the use of positioning gypsum board can save 30%

- Q: Sandwich panels on both sides of the metal, 50mm thick price

- About sixty yuan per square meter

- Q: Color steel tile foam sandwich board model is how the classification

- Common sandwich panels: foam sandwich panels, rock wool sandwich panels, polyurethane sandwich panels. Common specifications: roof board 980, wall board 950. Common thickness: 50mm, 75mm, 100m.

Send your message to us

1220x2440X12mm Red & Yellow Film Faced Plywood with Low Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 4000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords