Commercial Plywood with Poplar Material of Lowest Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Commercial Plywood with Poplar Material of Lowest Price

Product Description:

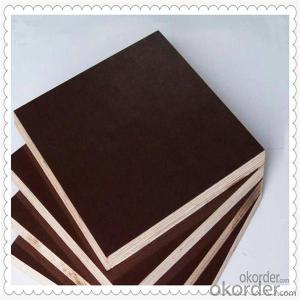

· Type: Plywood

· Material: Wood

· Wood Style: Panel

· Panel Type: Commercial Plywood

· Use: Indoor

· Place of Origin: China (Mainland)

· Model Number: 1220x2440mm

Packaging & Delivery:

1. Packaging Details: inner packing:0.20mm plastic bag; outer packing: pallets are covered with plywood or carton and then steel for strength

2. Delivery Detail: within 15 days after receiving the deposit

Product Specification:

Detailed Product Description | ||

Features | Face/back | melamine /veneer/pvc/hpl/ev (As you required) |

Glue | E1 or E2 ... (As you please) | |

Size | 1220*2440mm or 1830*2440mm | |

Thickness | 2.0mm~35mm | |

Core | poplar, combi etc. | |

Moisture | normal, moisture-proof, water-proof, eco-friendly | |

Payment & Shipping | MOQ | 1*20' container (negotiable) |

Port | Qingdao | |

Packing details | Inter packing: 0.20mm plastic bag Outer packing: pallets are covered with plywood or carton and then steel for strength | |

Delivery time | Within 15~20 days after 30% deposit or L/C | |

Payment terms | L/C,T/T | |

Supply ability | 50*40' HQ per Month | |

Advantages | Guarantee of 2 years | |

Competitive price | ||

ECO- friendly—— E1 grade, CARB P2 certificated | ||

High quality and excellent workmanship | ||

Company Info:

OKorder.com is an online building materials trading platform funded by CNBM (listed 267th on Fortune Global 2014) and is operated by CNBM International. CNBM International has more than 20 years trading experience and has established close business relationships with clients from over 160 countries.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: Color steel sandwich panels are prefabricated or on-site production processing

- Not prefabricated, is custom production.

- Q: I would like to buy some sandwich panels, I do not know where the quality is better?

- I came to tell you that we choose sandwich board is used in Zhejiang Bo Ya building materials, product quality is good, very cost-effective to buy things,

- Q: What is the difference between the ecological board and the sandwich board? Which is used to decorate better, what is the price? What are the top ten brands of the two boards?

- The ecological board is made of natural mineral stone powder and natural fiber as the basic raw material, through the inorganic gel technology modification process, through the mold, natural curing molding for the environmental protection and energy saving new materials, which does not contain formaldehyde, toluene inorganic natural environmental performance, Combined with the surface of the natural texture and sustained and efficient negative oxygen ion release, to achieve its natural properties of green building materials. Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor.

- Q: Density board, sandwich panels, solid wood particle board What is the difference between the three, which is better!

- Density plate (English: High Density Board (wood)), also known as fiberboard, is the wood, tree technology and other objects in the water soaked after hot grinding, pavement, hot pressed, is based on wood fiber or other plant fiber Raw materials, urea-formaldehyde resin or other suitable adhesive made of artificial plate. Because of its soft and impact resistance, high strength, uniform pressure after the uniform, but also easy to reprocessing in foreign countries is a good material for the production of furniture, but the disadvantage is poor water resistance. Medium and high density board, is a small diameter wood grinding and grinding in the high temperature and pressure to suppress, is now common, and our standards on the height of the board than the international standard several times lower, so the density board in China The use of quality has yet to be improved. Sandwich panel products are composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the composition of the polymer core insulation. These sandwich panels are easy to install, lightweight and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. The forming of the outer steel sheet takes into account the structural and strength requirements, and takes into account the appearance, the inner layer is formed into a flat plate to suit various needs.

- Q: What is the difference between the sandwich panel and the composite board?

- Metal sandwich panels are made of two-layer metal panels (or other material panels) for the surface material, insulation materials to do the core material, with adhesive composite or direct foam curing molding compound. Building insulation sheet industry in the insulation board refers to the sandwich panels, composite board is popular called. Metal composite panel in the industry refers to a layer of metal plate covered with another metal plate, in order to reduce the use of the effect (corrosion resistance, mechanical strength, etc.) under the premise of saving resources and reduce the cost of the effect.

- Q: Will the Yanmian sandwich color steel plate of the plant can reach the fire two grade requirements?

- Yanmian sandwich color of the core material is basalt and other natural ore as the main raw material, the high temperature melt into the fiber, adding the right amount of binder, curing and made. Is the same type (sandwich panel series) in the fire resistance of the strongest of a new type of fire board. Applicable to drying room, paint room, industrial equipment, construction, ship insulation, noise, etc., at the same time for electronic clean room, clean room, explosion-proof fire shop ceiling, partition and so on. Fire time is 80 minutes. Some information on "with 600 ℃ fire resistance, fire rating to A level."

- Q: What is the difference between the board and the core board? Usually where the place with sandwich panels where the use of laminates, such as the use of the shoe is the board, wardrobe with a sandwich panel? So what is the difference between the two

- Daxing board is made of two pieces of veneer stagnant stitching wood. Daxin board price is cheaper than the core board, the vertical (to the core material to distinguish) bending strength is poor, but the lateral bending pressure The strength is more ... but the general is best not to choose! 2. Plywood, also known as plywood, some people called the carefully board. Three or more layers by 1mm thick veneer sheet made of hot pressing. Plywood is generally divided into 3mm, 5mm , 9mm, 12mm, ... Plywood Optional plywood is made of multi-layer veneer staggered arrangement of the sheet. The outermost front panel is called the panel, the reverse is called the back plate. Core board.

- Q: Introduction of foam sandwich panels

- Foam sandwich panels beautiful appearance, bright color, the overall effect is good, it sets load, insulation, waterproof in one, and no secondary decoration, is a wide range of uses, especially in the construction site for temporary facilities such as office, Wall, etc., but also reflects the modern construction site of civilized construction, especially in the rapid installation and put into use, can be installed in the removable, material turnover index, there are obvious advantages, a substantial reduction in temporary construction site costs, Will be indispensable for new lightweight building materials.

- Q: The main sheet of glass wool cotton sandwich panels

- 1. Surface material / floor (color coated plate, galvanized sheet, stainless steel plate, aluminum foil paper, PVC, plywood, etc.) 1.1 Introduction of various sheet properties (1) color coated board The substrate is hot-dip galvanized or galvanized sheet, but also the use of electro-galvanized substrate, the surface of the paint is not bent off; (Two coated two) or the existence of quality problems such as loose edge serious, the middle loose heart, leakage coating, large serrated edge, serious Oval, uneven and so can not be used for the production of composite panels. (2) galvanized sheet Poor bonding is sometimes not handled well and needs to be handled. (3) stainless steel plate Good corrosion resistance, toughness difficult processing; bonding effect is sometimes bad, need to deal with. (4) aluminum foil Reinforced aluminum foil is a kind of aluminum foil and kraft paper folder between the glass fiber reinforced plastic composite material, with fire-retardant, fire and other functional characteristics, and beautiful, durable, is a new generation of insulation, insulation, sound insulation ideal supporting insulation The

- Q: What is the metal sandwich plate?

- 2 side metal plate composite other materials, such as rock wool, extruded board and so on.

Send your message to us

Commercial Plywood with Poplar Material of Lowest Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords