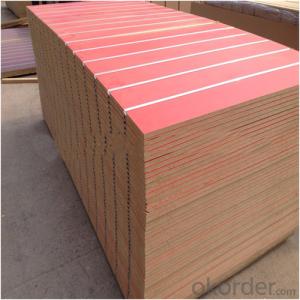

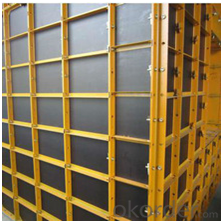

Concrete plywood formwork system Concrete plywood formwork system

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 mm

- Supply Capability:

- 30000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features

Transference to concrete is set up very easily. There is no need for any transference preparation.

1. Transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2. After installation of concrete, the surface looks like a mirror. (the cement does not stick.)

3. You are able to use film faced plywood until the plywood itself is damaged. (Strong with nailing and knifing)

4. Environmentally friendly. (Even after incineration, there is no hazardous substance.)

5. It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time

advantages

1.Lightweight, resistant to corrosion attack and water, easily combined with other materials and easy to clean and cut. it is more available with high-rise building and bridge construction.

2.Treating the film faced plywood’s edges with waterproof paint makes it highly water-and wear-resistant.

3.Due to its durability and easily handled surface it can be used in open environment in construction and building e.g. warehouses, railway wagons, floors and sidewalls of trucks etc. Corrosion resistance: not pollute the concrete surface.

4.Coating the film faced plywood with high-quality import films ensures hardness and damage resistance. The surface of the film faced plywood is hygienic and resistant to strong

detergents, which is important for farming constructions and storage of food products.

5.It can be used in conditions of high temperature drop, influence of moisture, detergent cleaning and provides protection against termites. Heat preservation performance is good, be helpful for winter construction. You don’t need to worry about the quality.

- Q: How to install the cold sandwich sandwich sandwich panels

- If the use of polyurethane cold storage board, then use the structure of the installation of the installation time can be reported to us can also install their own This is a drawing in accordance with the drawings can be installed

- Q: What is the eps sandwich panel

- Eps sandwich panels are: polystyrene sandwich panels 1, thermal insulation: No. Name Number of thermal conductivity systems (W / M2.K) 1 FRP panel (FRP) 0.23 2 polystyrene foam (EPS) 0.038-0.043 3 80mm thick composite plate <0.46 2, the surface of glass steel plate has a layer of excellent performance of the gel coat, the atmosphere, water and the general concentration of acid, alkali, salt and other media has a good chemical stability; surface finish, Good, do not change color, corrosion resistance, anti-sun, anti-aging

- Q: I would like to buy some sandwich panels, I do not know where the quality is better?

- Aisha Yili's products are good. Quality assurance, you can 30 days unconditional return policy. And the service attitude is also very good. Style is very novel, adequate inventory. There are tens of thousands of models, the product will be weeks on the new,

- Q: Rock wool color steel sandwich board rock wool bulk density

- 120 ~ 150kg / m ^ 3 Depending on the temperature difference, the temperature difference in the 130 ~ 180kg / m ^ 3 Attached to the industry standard

- Q: Is the foam sandwich board one meter high?

- Some we do the highest of 21 meters

- Q: Rock wool sandwich board standards which

- Rock wool core material: the use of density of 120kg / m? rock block staggered laying, the fiber perpendicular to the sandwich plate on the upper and lower surfaces, and close contact to enrich the sandwich panel of the entire vertical and horizontal. The combination of rock wool and rock wool and the upper and lower steel plates through the high-strength foaming agent to form a whole, sophisticated production process to ensure that the high-density rockwool insulation and metal plate between the inner wall can produce poles Strong adhesion, so that the rock wool sandwich panel has a very good stiffness.

- Q: Can the color steel sandwich panel be hit on a stainless steel tube?

- Playing is able to hit. But we have never done so, stainless steel too no thickness, eat nails is not strong, no effect. So do not agree with stainless steel.

- Q: Thickness of rock plate sandwich panels Drawings are written on the F50 color steel rock wool sandwich panels, I would like to ask F50 is the meaning of God, can represent the thickness of it? I asked whether the F50 can represent the thickness of 50 or just a model, in fact, the thickness of 100?

- I have a solution to it. F that Fire, should be the brand is Lokewei it, because Lokowei have 50F and 50C, there are 75F and 75C models, F is the fire board, C said the ordinary version, but 50 can not represent the thickness, because our Offer range, 50F and 50C have 50,80,100,120 mm ... and so the thickness, so 50 can not be the thickness of the thickness of the need for additional set. PS: 50 in Lokovo and intensity (density) have a relationship .50 strength is not high strength of 75. The higher the thickness the thicker the thickness

- Q: Steel structure, activities, such as sandwich panels board generally what kind of self-tapping screws fixed ah?

- Roof 75 stupid 135 self-tapping nail 100 stupid 165 self-tapping nail wall 50 stupid 75 self-tapping nail 75 stupid 100 self-tapping nail 100 stupid 125 tapping nail

- Q: Can the color steel sandwich panels be properly bent?

- Color steel plate sandwich panels can not be bent, it is surrounded by a fixed keel, can not bend! It works on the plane!

Send your message to us

Concrete plywood formwork system Concrete plywood formwork system

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 mm

- Supply Capability:

- 30000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords