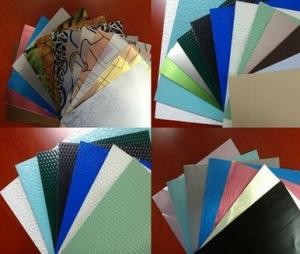

Aluminum Sheets for Sale Home Depot - Coated Aluminum Coil Sheet for Ceiling Panels with Bright Color and Lustre

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1' alloy:1050/1060/1100/3003/3004/3105/5005,5052,etc

2' thickness:0.1-1.2mm

3' width:700- 1600mm

4' coating thickness:

PE coat: one layer 16-17 μm, two layers 26-27 μm

PVDF coat: two layers 26-27μm

5' hardness:more than 2T

6' adhension:5J

7' flexibility:more than 2T

8' MEK resistance:≥100 times

9' ultimate strength(≥MPA):65-95

10' elongation(≥%):40

Application:

widely used for food cooking, freezing wrapping, storing etc, the main application are for household and catering, which are targeting for retail market and food service market, such as hypermarket, chain store and hotel, restaurant etc.

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT).

- Q: I have no idea, and I can't figure this out, and neither can my aunt and she's super smart. It's this project that's due on Monday, and if I can't get it turned in, then I get detention and a failing lab grade. The only information I have is it's $2.96 for a roll of aluminum, it contains 2.96 square meters, and it weighs .995 grams...

- This can be done, as crazy as it sounds. Aluminum has a molar mass of 26.98g and the stated sample (the roll) is $2.96 for 0.995g You would divide 0.955 by 26.98. This gives you 0.0369, which is the amount of moles of aluminum in the roll. Then you need to use Avogadro's number. This is 6.02*10^23, and is the amount of particles in a mole. Avogadro's number multiplied by 0.0369 gives you 2.22138*10^22. This is the amount of aluminum atoms in the roll. Now, you divide the price ($2.96) by the amount of aluminum atoms (2.22138*10^22) to get the price per atom. Price per atom of aluminum in the stated sample: $1.332505*10^-22 (This is equivalent to .$0.0000000000000000000001332505) I hope this helps.

- Q: How is the strength and durability of aluminum sheets determined?

- The determination of the strength and durability of aluminum sheets involves the utilization of various testing methods and parameters. A key factor in establishing the strength of these sheets is their alloy composition. Different compositions of alloys possess different levels of strength, and the addition of certain elements to the aluminum can enhance its strength properties. In order to assess the strength of aluminum sheets, the commonly employed method is tensile testing. This procedure entails subjecting a sample of the sheet to tension until it fractures. Throughout the test, the load and deformation are measured, and the ultimate tensile strength (UTS) and yield strength are established. The UTS signifies the maximum amount of stress that the sheet can endure before failure, whereas the yield strength is the stress at which the material begins to deform plastically. The thickness of aluminum sheets is another crucial consideration when determining their strength and durability. Generally, thicker sheets tend to exhibit greater strength and durability compared to thinner ones due to the increased cross-sectional area that contributes to their load-bearing capacity. Apart from alloy composition and thickness, the strength and durability of aluminum sheets are also influenced by the manufacturing process. Factors such as rolling and heat treatment have the ability to alter the microstructure of the aluminum, thereby affecting its mechanical properties. Effective control of these processes is essential in order to ensure consistent strength and durability across all sheets. Moreover, the resistance to corrosion is often evaluated for aluminum sheets. Aluminum naturally forms a protective oxide layer, which enhances its resistance to corrosion. However, specific coatings or treatments can be applied to further enhance this resistance, depending on the intended application. In conclusion, the determination of the strength and durability of aluminum sheets is achieved through a combination of factors including alloy composition, thickness, manufacturing processes, and testing methods such as tensile testing. These factors collectively govern the mechanical properties and resistance of aluminum sheets to various forms of stress, rendering them suitable for a wide array of applications.

- Q: Can aluminum sheets be an alternative to glass in certain applications?

- Yes, aluminum sheets can be an alternative to glass in certain applications. Aluminum sheets offer several advantages over glass, making them a suitable choice in specific scenarios. Firstly, aluminum sheets are lightweight and durable, making them ideal for applications where weight is a concern, such as in aerospace or automotive industries. Glass, on the other hand, is relatively heavy and brittle, which can limit its use in certain environments. Additionally, aluminum sheets have excellent corrosion resistance, making them suitable for applications in marine or coastal environments where glass may deteriorate over time due to exposure to saltwater. Aluminum sheets also have a high strength-to-weight ratio, allowing for greater design flexibility and structural integrity compared to glass. Moreover, aluminum sheets can provide better thermal insulation properties compared to glass. They offer improved heat transfer resistance, which can be advantageous in applications where temperature control is crucial, such as in the construction industry. Furthermore, aluminum sheets can be more cost-effective than glass in certain applications. The production and installation costs of aluminum sheets are often lower compared to glass, making them a more economical choice for large-scale projects. However, it is important to note that glass still has its own unique properties and advantages that make it the preferred choice in many applications, such as its transparency and optical clarity. Glass also offers better resistance to scratches and chemical corrosion compared to aluminum sheets. In conclusion, while aluminum sheets can be a viable alternative to glass in certain applications due to their lightweight, durability, corrosion resistance, thermal insulation properties, and cost-effectiveness, the choice between the two materials ultimately depends on the specific requirements and constraints of the application in question.

- Q: Cooks are warned not to use aluminum cookware when preparing acidic foods. Why?

- Plain okorder /... Hope this helps.

- Q: What specific requirements or considerations are necessary when using aluminum sheets in marine environments?

- <p>In marine environments, aluminum sheets must meet specific requirements to ensure durability and resistance to corrosion. These include using high-grade aluminum alloys, such as 5083 or 5086, known for their excellent resistance to saltwater corrosion. Protective coatings like anodizing or applying marine-grade paints can further enhance corrosion resistance. Additionally, the aluminum sheets should be designed to withstand the harsh conditions of marine environments, including high humidity, UV radiation, and mechanical stress. Regular maintenance and inspection are also crucial to prevent corrosion and ensure the longevity of aluminum structures in marine settings.</p>

- Q: Is it suitable to use aluminum sheets in outdoor settings where they will be subjected to weather conditions?

- <p>Yes, aluminum sheets can be used for outdoor applications, even when exposed to weathering. Aluminum is a durable and corrosion-resistant material, which makes it suitable for outdoor use. It does not rust like iron or steel and can withstand various weather conditions. However, it's important to use aluminum alloys specifically designed for outdoor use, and to apply protective coatings or finishes to enhance its resistance to weathering and extend its lifespan.</p>

- Q: Im wondering what type of clutch would be better for my fox body mustang. A aluminum or steal. And why

- aluminum if you are drag racing ( have to learn to feather the clutch a bit) STEEL on the street( easier to keep the fire lit for mere mortals ) course you can use aluminum on the street--most people cant, because you have to be easy with the clutch-but it gives you an excuse why people cant borrow your car

- Q: Do these frames rust? For example here is a link. But I am genuinely curious because in swimming pools, the hand rails going into the swimming pool have the same finish as this bike frame and they have white corrosion marks. Thank you in advanced

- pool rails will not be the same thing as bike aluminum bikes are not immersed in water aluminum cannot rust though it might corrode in salt water or air wle

- Q: What are the advantages of using aluminum sheets over other materials?

- Using aluminum sheets offers several advantages compared to other materials. Firstly, aluminum is lightweight, making it easier to handle and transport than heavier materials like steel. This convenience is especially beneficial in industries where weight reduction is important. Secondly, aluminum sheets have a high strength-to-weight ratio. Despite being lightweight, they can withstand heavy loads and impacts, making them ideal for construction, aerospace, and automotive industries that require durability and structural integrity. Additionally, aluminum is highly resistant to corrosion. It forms a protective oxide layer that prevents rust and corrosion, even in harsh environments. This makes it suitable for outdoor applications, such as building facades, roofing, and marine structures, where exposure to moisture and other corrosive elements is a concern. Moreover, aluminum is highly malleable, allowing it to be easily shaped into various forms and sizes. It can be rolled into thin sheets or extruded into complex profiles, offering design flexibility for different applications. This versatility makes aluminum sheets adaptable in a wide range of industries, including manufacturing, architecture, and transportation. Furthermore, aluminum is a sustainable and recyclable material. It has a relatively low melting point, requiring less energy to recycle compared to other materials. This makes aluminum sheets a more sustainable choice, promoting environmental conservation and reducing the carbon footprint. In conclusion, the advantages of using aluminum sheets over other materials include their lightweight nature, high strength-to-weight ratio, corrosion resistance, malleability, and sustainability. These properties make aluminum sheets an excellent choice for various applications where performance, durability, and environmental considerations are essential.

- Q: does anyone know how aluminum recycling works in term of redox reaction ( oxidizing, reduced, oxidizing agent, reducing agent?). how is that relate to the process of electrochemistry?

- Aluminum recycling is done by just melting the cans back into molten metal. There are reactions, but those deal with the impurities, not the aluminum. See the reference.

Send your message to us

Aluminum Sheets for Sale Home Depot - Coated Aluminum Coil Sheet for Ceiling Panels with Bright Color and Lustre

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords