5052 Aluminum Sheets Custom 1060 Embossed Aluminum Plate/Aluminum Material Floor Plates

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 360 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1060 Embossed Aluminum Plate/Aluminum Material Floor Plates

1. Commodity: 5083 Aluminium Plain Sheet for Marine Use

2. Alloy No.: 050 1060 1100 3003 3004 3104 3005 3105 5005 5052 8011

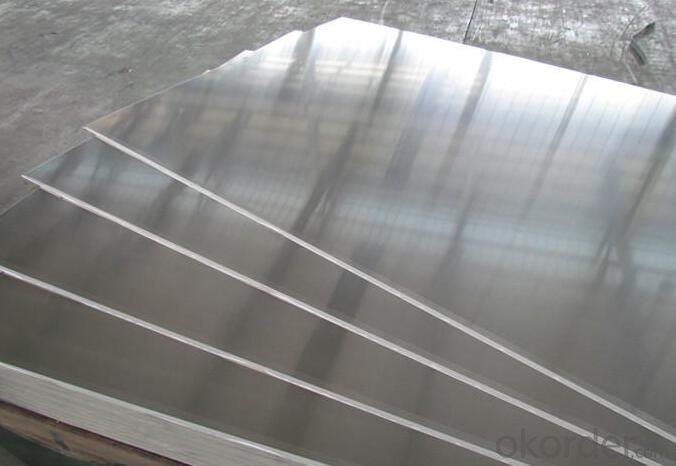

3. Size: Thickness: 0.15-5.00mm(Tolorance±0.02mm) Width:200-1600mm(Tolorance±1mm) Length:500-1500mm(Tolorance±1mm)

4.Application:

1) air plane, refrigerators ,audio equipment

2)building materials: ceilings, walls

3)telephones, digital cameras

4) plastic composite board, aluminum and plastic pipe

5.Month Capacity: 5000MT/Month

6.Pattern: 2 bars, 3 bars, 5 bars, diamond bar

1. | Item | Aluminum plate/ Aluminum sheet,aluminium plate price, aluminium chequer plate,aluminium sheet,aluminium sheet price | |

2. | Standard | ATSTM,AISI,JIS,EN,GB | |

3. | Material | 1060,1200,1100,a1100P,3003,3004,5052,5652,5154,5254,5454,5083, 5086,5056,5456,2A21,2024,2014,6061,6063,7072,7075,etc. | |

4. | Specifications | Thickness | 0.5mm~200mm |

Width | 100mm~3000mm | ||

Length | 2m,3m,5.8m,6m,or as required | ||

6. | Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. | |

7. | Price Term | Ex-work, FOB, CIF , CFR, etc. | |

8. | Payment Term | T/T, L/C, Western Union, etc. | |

9. | Delivery Time | According to order’s quantity. | |

10. | Package | Export standard package: bundled wooden box, suit for all kinds of transport, or be required. | |

11. | MOQ | 500kg | |

12. | Export to | Singapore,Indonesia,Ukraine,Korea,Thailand, Viet Nam, Saudi Arabia, Brazil, Spain, Canada, USA, Egypt, Iran, India, Kuwait, Dubai, Oman, Kuwait, Peru, Mexico, Iraq,Russia,Malaysia, etc. | |

13. | Application | 1) Kitchenware, food and chemical products processing and storage devices; 2) Aircraft fuel tanks, oil pipe, rivets, wire; 3) Cans cover, car body panels, steering plates, stiffeners, brackets and other components; 4) Manufacturing trucks, tower building, ship, train, furniture, machinery parts, precision machining with the tubes, rods, shaped, sheet metal. | |

Packaging detail: First, plastic cloth; Second, Pearl Wool ; Third, wooden cases with dry agent ,without fumigation, wooden pallets

Delivery detail: Within 25days

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

- Q: How are aluminum sheets tested for quality and compliance with industry standards?

- Quality and compliance with industry standards for aluminum sheets are ensured through a comprehensive range of tests and inspections. These tests guarantee that the desired specifications and performance criteria are met by the sheets. Visual inspection is one of the commonly utilized tests, where the sheets are thoroughly examined for any surface defects like scratches, dents, or cracks. This examination is crucial to ensure a flawless and smooth appearance. Furthermore, dimensional checks are carried out to verify the thickness, width, and length of the sheets. Precise measurements are essential to meet the specific requirements of the intended application. Various tests are conducted to evaluate the mechanical properties. Tensile strength tests assess the maximum load the aluminum sheet can bear before breaking. This aids in determining the structural integrity of the sheet and its ability to withstand external forces. Similarly, hardness tests measure the sheet's resistance to indentation or penetration, providing insights into its durability and resistance to wear. Chemical composition analysis is also undertaken to ensure that the aluminum sheets contain the necessary alloying elements within the specified limits. This analysis helps confirm that the material composition aligns with industry standards, as different alloy compositions can affect the mechanical properties of the sheets and their suitability for various applications. Corrosion resistance tests assess the sheet's capacity to withstand environmental factors like moisture, chemicals, and temperature variations, thereby evaluating its surface integrity. This evaluation is particularly important for applications where aluminum sheets are exposed to corrosive substances or harsh environments. In addition to these tests, non-destructive testing techniques such as ultrasonic testing or eddy current testing may be employed on aluminum sheets. These methods help identify internal defects or irregularities that may not be visible through visual inspection alone. Overall, a combination of visual inspections, dimensional checks, mechanical tests, chemical composition analysis, and surface integrity evaluations are utilized to ensure that aluminum sheets meet the quality standards and compliance requirements set by the industry. These rigorous testing procedures guarantee that the sheets are suitable for their intended purpose and fulfill the expectations of customers.

- Q: Can 101 aluminum sheets be bent or formed into different shapes?

- Certainly! It is indeed possible to bend or shape 101 aluminum sheets into various forms. Aluminum possesses high malleability, meaning it can be shaped effortlessly without any risk of breaking or cracking. The specific grade of aluminum, such as 101, signifies the alloy composition and might possess specific properties that make it more suitable for bending and shaping. Nevertheless, the capacity to bend or shape aluminum sheets also relies on their thickness; thicker sheets may necessitate greater force and specialized equipment. In conclusion, with the correct tools and techniques, it is feasible to bend or shape 101 aluminum sheets into diverse shapes to fulfill specific requirements.

- Q: Is the chemical formula for Aluminum Sulfate Al2(SO4)3?How and why is Al2(SO4)3 wrong?

- Aluminium sulfate or Aluminium Sulphate, written as Al2(SO4)3 or Al2O12S3 Aluminium sulfate is an industrial chemical used as a flocculating agent in the purification of drinking water[2][3] and waste water treatment plants, and also in paper manufacturing. Aluminium sulfate is sometimes incorrectly referred to as alum but alums are closely related compounds typified by KAl(SO4)2.12H2O. The anhydrous form occurs naturally as a rare mineral millosevichite, found e.g. in volcanic environments and on burning coal-mining waste dumps. Aluminium sulfate is rarely, if ever, encountered as the anhydrous salt. It forms a number of different hydrates, of which the hexadecahydrate Al2(SO4)3?16H2O and octadecahydrate Al2(SO4)3?18H2O are the most common. The heptadecahydrate, whose formula can be written as [Al(H2O)6]2(SO4)3?5H2O, occurs naturally as the mineral alunogen. [1]

- Q: i need to know these things please....can aluminium withstand the forces of being in a cargo hold on a air freight, can it withstand extreme temps and to what extent an is it microwavable?? please help me

- No metals are microwavable, they will ruin any microwave oven by producing sparks. Even ceramic plates with a little metallic paint eg of silver will spark. Aluminium on its own has little strength but when mixed with small amounts of eg copper or manganese it aquires great strength while remaining light. In addition it has the advantage of being very resistant to oxidation and corrosion. It is certainly used extensively in aircraft construction. Due to being non toxic it used to make cans for beers, soft drinks (sodas) etc However it doesn't stand up well to high temperatures, its melting point is just at 660 degrees celsius, by comparison for iron it is 1540 and tungsten 3420.

- Q: How do you cut aluminum sheets?

- Aluminum sheets can be cut using various methods such as shearing, sawing, laser cutting, or using water jet cutters. The most suitable method depends on the thickness and size of the aluminum sheet as well as the desired precision and efficiency.

- Q: you can turn in aluminum cans for cash some are called golden goats

- Aluminum okorder

- Q: This question asks about the effects of using aluminum sheets in the construction industry on the environment.

- <p>The environmental impacts of using aluminum sheets in construction are multifaceted. On the positive side, aluminum is lightweight, which reduces energy consumption during transportation. It is also recyclable, with a high percentage of construction aluminum being recycled, reducing waste. However, the production of aluminum is energy-intensive, contributing to greenhouse gas emissions. Additionally, mining for bauxite, the primary source of aluminum, can lead to habitat destruction and water pollution. Despite these concerns, aluminum's durability and resistance to corrosion can extend the lifespan of buildings, reducing the need for frequent replacements and thus the overall environmental footprint over time.</p>

- Q: What are the different methods of surface engraving aluminum sheets?

- There are several methods of surface engraving aluminum sheets, each offering unique advantages and suitable for different applications. 1. Mechanical Engraving: This traditional method involves using a rotating cutting tool, such as a milling machine or a router, to physically remove material from the surface of the aluminum sheet. It is a precise and versatile technique that can create intricate designs and deep engravings. Mechanical engraving is commonly used for signage, branding, and decorative purposes. 2. Laser Engraving: This modern and highly precise method uses a laser beam to vaporize or melt the surface of the aluminum sheet, creating a permanent mark. Laser engraving offers great control over the depth, speed, and intensity of the engraving, allowing for detailed and accurate results. It is widely used in industries like aerospace, automotive, and electronics for part identification, serial numbers, and barcodes. 3. Chemical Etching: Also known as chemical milling or photochemical machining, this process involves coating the aluminum sheet with a photosensitive mask and exposing it to UV light through a stencil or artwork. The exposed areas are then chemically etched, removing the material and creating the desired design. Chemical etching offers high precision, repeatability, and the ability to engrave very thin lines or complex patterns. It is often used in electronic components, nameplates, and decorative applications. 4. Diamond Drag Engraving: This method uses a diamond-tipped stylus that is dragged across the surface of the aluminum sheet, scratching or indenting it to create the engraving. Diamond drag engraving is commonly used for industrial applications, such as part identification and serial numbering, as well as for creating durable and long-lasting markings on aluminum sheets. 5. Rotary Engraving: In this technique, a rotating cutting tool is used to remove the material from the aluminum sheet, similar to mechanical engraving. However, rotary engraving is typically used for larger and thicker aluminum sheets and is often employed in industrial settings for marking, labeling, and identification purposes. Each of these methods has its own advantages and is suitable for different applications, so choosing the right engraving method for aluminum sheets depends on factors such as the desired design, level of detail, durability requirements, and the intended use of the engraved product.

- Q: Which is better aluminum or stainless steel?

- Depending on what your using it for. Stainless steel is much stronger in strength seeing Aluminum has it's weak points and can bend under stress, and is also weak under large amounts of heat. I use stainless steel bolts and nuts for my exhaust systems, and starters on my truck, and they still haven't rusted as of yet.

- Q: Are aluminum sheets resistant to saltwater corrosion?

- Yes, aluminum sheets are generally resistant to saltwater corrosion. Aluminum has a natural ability to form a protective oxide layer when exposed to air or water, including saltwater. This oxide layer acts as a barrier, preventing further corrosion and protecting the underlying metal. Additionally, aluminum is lightweight and durable, making it a popular choice for various marine applications such as boats, shipbuilding, and offshore structures. However, it is important to note that the resistance to saltwater corrosion can vary depending on the specific alloy and surface treatment of the aluminum sheets. Therefore, proper selection of the appropriate alloy and protective coatings can further enhance the corrosion resistance of aluminum sheets in saltwater environments.

Send your message to us

5052 Aluminum Sheets Custom 1060 Embossed Aluminum Plate/Aluminum Material Floor Plates

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 360 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords