1060 Anti-Corrosion Color Coated Aluminum Coil for Roofing and Cladding System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1060/1050 Aluminium Coil for Transformer/ Electronic Components

l Product Description

Alloy: | A1100, A1050, A1060,A3003, A3004, A3005, A3105 , A5052, , A5754, A8011 etc. | |

2 | Temper: | H14, H16, H18, H24 etc. |

3 | Thickness: | 0.2mm - 2.0mm |

4 | Width: | 15mm - 1600mm |

5 | Color: | chromic,white,metallic and so on(Customized, choose from RAL color chart or refer to customers' counter sample.) |

6 | Coating: | Polyester(mainly),Fluorocarbon(mainly),polyurethane and epoxy coating ect. |

7 | Coating thickness: | PVDF≥25 micron; PE≥18 micron. |

8 | Surface Quality: | be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use. |

9 | Mechanical Property: | Chemical Composite and Mechanical Property are meted with GB/T, ASTM, ENAW Standard. |

10 | Interior diameter: | 105mm or 405mm or 505mm |

11 | Coating hardness: | (pencil hardness) more than 2H |

12 | Impact resistance: | no cracking and peeling(≥50kg/cm) |

13 | Flexibility(T-bend) : | ≤ 2T |

14 | MEK resistance: | more than 100 |

15 | Packaging Detail: | standard export packing in carton and wooden pallet |

16 | Payment Detail: | 30% deposit by T/T in advance,70% balance should be paid upon BL copy |

18 | Application: | roofs, facade cladding, ceilings, aluminum curtains, composite panels, pipe wrap, advertisement plates, instrument panels, and other uses. |

l Packaging & Delivery

Packaging detail: pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: within 30 days after we get your 30% deposit or L/C

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

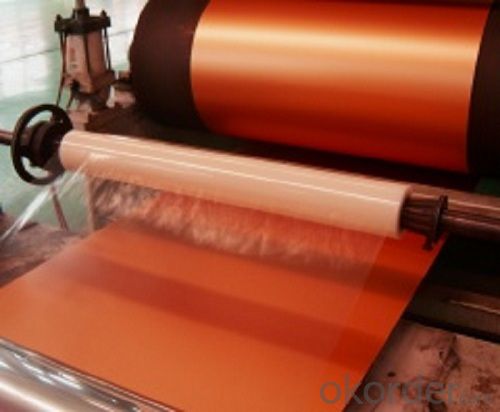

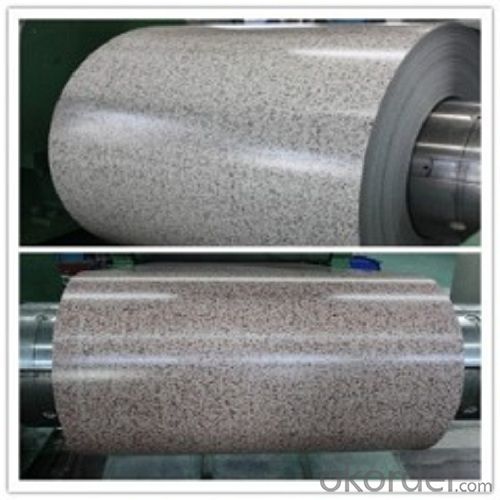

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: Can aluminum coils be used in the production of consumer electronics?

- Yes, aluminum coils can be used in the production of consumer electronics. Aluminum is a lightweight and versatile metal that offers several advantages in the manufacturing of consumer electronic devices. It has excellent thermal conductivity, which makes it ideal for heat dissipation in electronic components such as motors, transformers, and power supplies. Aluminum coils are commonly used in the production of electronic devices such as smartphones, laptops, and tablets. They are often employed in the construction of the device's housing or casing, providing a lightweight and durable solution. Aluminum is also non-magnetic, which makes it suitable for electronic devices that require minimal interference with magnetic fields. Additionally, aluminum coils offer good electrical conductivity, making them useful in applications that require efficient transmission of electrical signals. They are often employed in the production of antennas, connectors, and other electronic components that require high conductivity. Moreover, aluminum is a highly recyclable material, which aligns with the growing demand for sustainable manufacturing practices. The use of aluminum coils in consumer electronics not only provides functional benefits but also contributes to a greener and more environmentally friendly production process. In summary, aluminum coils can indeed be used in the production of consumer electronics due to their excellent thermal conductivity, lightweight and durable properties, good electrical conductivity, and recyclability.

- Q: What are the color options available for aluminum coils?

- The color options available for aluminum coils are typically vast and varied, ranging from standard colors like white, black, and silver to a wide array of custom colors and finishes. Some popular options include metallic, matte, gloss, and textured finishes, allowing for endless possibilities in terms of design and aesthetics.

- Q: This question asks about the environmental impact of aluminum coils, including potential effects on the ecosystem and human health.

- <p>Aluminum coils, when produced and used responsibly, have minimal environmental impact. However, improper disposal or manufacturing can lead to pollution. Aluminum production requires significant energy, contributing to greenhouse gas emissions. During manufacturing, if not managed properly, can release harmful substances into the air and water. Yet, aluminum is highly recyclable, reducing its environmental footprint over time. When disposed of improperly, aluminum can contribute to litter and leach harmful substances into the soil and water, affecting wildlife and potentially human health. Responsible recycling and manufacturing practices are crucial to mitigate these effects.</p>

- Q: What are the potential health hazards linked to the use of aluminum coils?

- <p>There are concerns about the use of aluminum coils due to the possibility of aluminum leaching into food during cooking. Aluminum has been linked to various health issues, including cognitive decline and Alzheimer's disease, although the evidence is not conclusive. Additionally, aluminum exposure may lead to bone and neurological disorders. However, the health risks associated with aluminum coils are still a subject of debate among researchers. It's recommended to minimize exposure to aluminum by using alternative cooking methods or materials, such as stainless steel or cast iron.</p>

- Q: What are the various categories of aluminum coils based on their characteristics and applications?

- <p>Aluminum coils are categorized based on their thickness, alloy composition, surface treatment, and temper. The main types include: 1) Thickness-based: thin gauge, medium gauge, and thick gauge coils. 2) Alloy composition: 1000 series (99% aluminum), 3000 series (aluminum-manganese), 5000 series (aluminum-magnesium), 6000 series (aluminum-silico-magnesium), and 7000 series (aluminum-zinc). 3) Surface treatment: mill finish, anodized, painted, and coated. 4) Temper: O (annealed), H (strain hardened), W (solution heat treated), and T (thermally treated to various strengths). Each type serves specific industries such as construction, automotive, packaging, and aerospace.</p>

- Q: Are aluminum coils suitable for fire-resistant applications?

- No, aluminum coils are not suitable for fire-resistant applications. Aluminum has a low melting point and is highly flammable, making it a poor choice for fire-resistant applications. In fact, aluminum can even contribute to the spread of fire due to its combustible nature. For fire-resistant applications, materials such as steel or fire-resistant alloys are recommended as they have a higher melting point and better resistance to fire. These materials are designed to withstand high temperatures and are less likely to contribute to the spread of fire.

- Q: What are the various techniques used in the manufacturing process to create insulation for aluminum coils?

- <p>Aluminum coil insulation is produced using several methods, including lamination, extrusion, and coating. Lamination involves stacking thin sheets of aluminum with insulating material between them. Extrusion is a process where aluminum and insulation materials are pushed through a die to create a continuous profile. Coating methods apply a layer of insulating material directly onto the aluminum coil surface. These methods ensure the insulation maintains its properties under varying conditions, providing electrical isolation and protection against environmental factors.</p>

- Q: Can aluminum coils be embossed or textured?

- Aluminum coils possess the capability to undergo embossing or texturing, thereby enabling the creation of patterns or designs on their surface. This can be achieved through mechanical or chemical processes. The resulting embossed or textured surface not only enhances the visual appeal but also improves the functionality of the aluminum coil, by augmenting its grip or minimizing glare. Consequently, these aluminum coils, with their embossed or textured features, have found widespread utilization across industries like construction, automotive, and packaging.

- Q: What are the various classifications of aluminum coil grades?

- <p>Aluminum coils are classified into different grades based on their composition and properties. The most common grades include 1000 series (99% pure aluminum), 3000 series (aluminum-manganese alloys), 5000 series (aluminum-magnesium alloys), and 6000 series (aluminum-silico-magnesium alloys). Each series has specific characteristics, such as corrosion resistance, formability, and strength, which determine their suitability for various applications like construction, transportation, and packaging. Additionally, there are 2000 series (aluminum-copper alloys), 4000 series (aluminum-silicon alloys), 7000 series (aluminum-zinc-magnesium alloys), and 8000 series (other alloys), each with unique properties and applications.</p>

- Q: What are the different types of aluminum coils available in the market?

- There are several different types of aluminum coils available in the market, each with its own unique characteristics and applications. 1. Plain Aluminum Coils: These are basic aluminum coils that are typically used for general applications. They have a smooth surface and are often used in construction, automotive, and packaging industries. 2. Color Coated Aluminum Coils: These coils are coated with a layer of paint or other finishes to enhance their aesthetic appeal and provide additional protection against corrosion. They are commonly used in the manufacturing of building facades, signage, and decorative applications. 3. Embossed Aluminum Coils: These coils have a textured or patterned surface, which gives them a decorative and non-slip finish. They are often used in applications where aesthetics and functionality are important, such as flooring, staircases, and decorative panels. 4. Anodized Aluminum Coils: These coils undergo an anodizing process, where a protective oxide layer is formed on the surface of the aluminum. This enhances their corrosion resistance and makes them suitable for outdoor applications, such as architectural elements, electronic components, and aerospace industry. 5. Pre-painted Aluminum Coils: These coils come with a pre-applied paint coating, which eliminates the need for additional painting or finishing. They are commonly used in industries that require high-quality, durable, and color-consistent products, such as automotive, appliances, and electronics. 6. Heat Exchanger Aluminum Coils: These coils are specifically designed for heat transfer applications, such as air conditioning and refrigeration systems. They have a high thermal conductivity and are often made from alloy grades that offer excellent corrosion resistance in harsh environments. It is important to consider the specific requirements and intended use of the aluminum coil before making a purchase. This will help ensure that the appropriate type of coil is selected for the desired application, thereby optimizing performance and longevity.

Send your message to us

1060 Anti-Corrosion Color Coated Aluminum Coil for Roofing and Cladding System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords