AA1050 CC Prepainted Aluminum Roofing Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA1050 CC Prepainted Aluminium Coils Used for Construction Description

AA1050 CC Prepainted Aluminium Coils Used for Constructionare widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

Direct Continuous Aluminium Foil Stock in Coil is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of AA1050 CC Prepainted Aluminium Coils Used for Construction

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

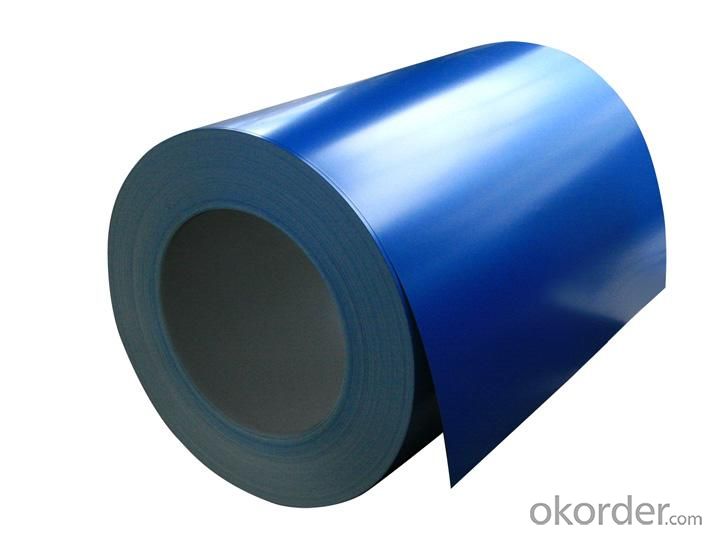

3.AA1050 CC Prepainted Aluminium Coils Used for Construction Images

4.AA3003 Prepainted Aluminium Coils Used for Construction Specification

Alloy | AA1050 CC |

Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

Thickness | 0.03mm-3.0mm |

Width | 30mm-1700mm |

Coating | PE,PVDF,Epoxy |

Painting Thickness | Standard 16-25 Mic, max 40 Mic |

Color | According to RAL colors or customers' samples |

Standard | GB/T 17748-1999 |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2000mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Can aluminum coils be used in food processing applications?

- Yes, aluminum coils can be used in food processing applications. Aluminum is a highly versatile and commonly used material in the food industry because of its numerous benefits. Aluminum coils are lightweight, durable, and have excellent thermal conductivity, making them ideal for applications that require even and efficient heat transfer. In food processing, aluminum coils are often used in equipment such as heat exchangers, evaporators, and refrigeration units. They are used to cool, heat, or maintain the temperature of various food products during processing, storage, or transportation. The excellent thermal conductivity of aluminum ensures that heat is evenly distributed, helping to preserve the quality and taste of the food. Additionally, aluminum is a non-toxic and non-reactive metal, which means it does not affect the flavor or composition of the food being processed. It also has a natural resistance to corrosion, ensuring that the coils do not contaminate the food and are easy to clean and maintain. Furthermore, aluminum is a sustainable and recyclable material, aligning with the growing demand for environmentally friendly practices in the food industry. Its lightweight nature also contributes to energy efficiency and reduced transportation costs. Overall, aluminum coils are a safe, efficient, and reliable choice for food processing applications, meeting the stringent requirements of the industry while maintaining the quality and safety of the processed food.

- Q: I had a small exclusive group of friends in high school of nine people. For Christmas every year we'd have a get-together and exchange gifts. Now, I was never fond of the, He got something different! or, Why did she get a book and I got a scarf? So I would always give my friends each the same thing, but personalized for them.One year I made aluminum foil sculptures for them because I was especially poor...And they loved them! They ranged from a dragon, an elephant, a pacifier, to a tiny martini glass. I was really surprised that everyone liked them.So do you think that I could make these and sell them at craft fairs? I don't know...it's just something I've been thinking about recently and wondering if it would work.

- It would have to be something they could not make by themselves. It would have to be durable. It would also help if the sculpture is useful in some way. Hey, I am just telling you what sells, from long experience. Maybe you would like to teach a class in foil sculpture instead. Try offering a class on Craigslist and see if anyone signs up. Or you could do videos or a pamphlet and sell those on Ebay. .

- Q: How are aluminum coils coated for color matching and aesthetic purposes?

- The process of coil coating is commonly used to coat aluminum coils for color matching and aesthetic purposes. It is a continuous and highly automated process where a layer of paint or coating is applied onto the surface of the aluminum coil. To start the coil coating process, the aluminum coil is thoroughly cleaned to remove dirt, grease, and oxidation. This is done using chemical cleaning agents and mechanical scrubbing methods to ensure a clean and smooth surface. Once the cleaning process is complete, a primer is applied to the aluminum coil. The primer acts as a bonding agent, improving the adhesion of the subsequent layers of paint or coating. It also helps to prevent corrosion on the aluminum surface. After the primer is applied, the aluminum coil undergoes a series of rollers where the desired color coating is applied. This can be done through various methods such as coil coating, spray coating, or powder coating. Coil coating is the most common method, involving the application of a liquid paint or coating onto the metal coil surface. The coating is then cured or dried using heat to ensure proper adhesion and durability. In order to achieve color matching and aesthetic purposes, the paint or coating used is often customized to specific color palettes or customer requirements. This customization is achieved by using a wide range of pigments and additives that alter the color, texture, and gloss level of the coating. Furthermore, specialized coatings can be applied to aluminum coils to enhance their aesthetic properties. For example, there are coatings available that give the appearance of natural wood or stone, providing a more visually appealing finish. Overall, the process of coating aluminum coils for color matching and aesthetic purposes involves thorough cleaning, priming, and the application of customized paint or coatings. This ensures that the aluminum coils meet the desired aesthetics while also providing durability and protection against corrosion.

- Q: What specific conditions or precautions need to be taken into account when storing and transporting steel wires intended for coiling purposes?

- <p>Yes, there are special requirements for storing and transporting steel wires for coiling. These wires must be kept dry to prevent rust and should be stored in a cool, dry place away from direct sunlight or extreme temperatures. They should be handled carefully to avoid kinks or deformations. When transporting, it's important to secure the coils to prevent shifting during transit, which could cause damage. Additionally, the packaging should be robust enough to protect the wires from moisture and physical damage.</p>

- Q: Can aluminum coils be used in chemical processing plants?

- Yes, aluminum coils can be used in chemical processing plants. Aluminum is resistant to many chemicals, especially in non-acidic environments. It is lightweight, has good thermal conductivity, and can withstand high temperatures, making it suitable for various applications in chemical processing plants.

- Q: What are some normal everyday products made from aluminum that I can use to recycle?

- Aluminum siding is large. I positioned vinyl siding on my homestead, and recycled the aluminum. the money I have been given from the the aluminum rather made siding my homestead a low-value project, and it greater beneficial the linked fee of my homestead.

- Q: Can aluminum coils be used for automotive heat shields?

- Automotive heat shields can indeed utilize aluminum coils. Aluminum, known for its outstanding thermal conductivity and high melting point, is frequently employed as a heat shield material. Its lightweight nature and remarkable resistance to corrosion make it particularly well-suited for automotive purposes. By effortlessly molding aluminum coils into the desired configuration, effective heat insulation can be attained, safeguarding delicate components from the engine or exhaust system's excessive heat. Moreover, aluminum is cost-efficient and easily accessible, contributing to its widespread preference as an automotive heat shield material.

- Q: Are there any specific certifications or qualifications required for aluminum coil suppliers?

- Yes, there are specific certifications and qualifications required for aluminum coil suppliers. These may include ISO certifications, quality management systems, and adherence to industry standards such as ASTM (American Society for Testing and Materials) or EN (European Norm) specifications. Additionally, suppliers may be required to meet certain regulatory requirements, such as those related to environmental sustainability or occupational health and safety.

- Q: What are the factors that affect the price of aluminum coils?

- There are several factors that can influence the price of aluminum coils. These include the cost of raw materials, such as the price of aluminum ingots, which can fluctuate based on global supply and demand dynamics. Additionally, factors like production and manufacturing costs, energy expenses, transportation costs, and market competition can all impact the final price of aluminum coils.

- Q: Are aluminum coils suitable for solar panel applications?

- Yes, aluminum coils are suitable for solar panel applications. Aluminum is a lightweight and highly conductive material that has several advantages for solar panels. Firstly, aluminum coils can effectively transfer and dissipate heat, which is crucial for maintaining the efficiency and lifespan of solar panels. Aluminum's excellent thermal conductivity helps in reducing the temperature of the solar cells, preventing overheating and potential damage. Secondly, aluminum coils are highly resistant to corrosion, making them an ideal choice for outdoor solar panel installations. Solar panels are exposed to various weather conditions, including rain, snow, and humidity, which can lead to corrosion and degradation. Aluminum's natural oxide layer acts as a protective barrier, preventing corrosion and increasing the durability of the solar panels. Additionally, aluminum is a cost-effective material that is widely available and easy to manufacture. Its lightweight nature also contributes to easier transportation and installation of solar panels, reducing overall costs. In conclusion, aluminum coils are suitable for solar panel applications due to their excellent thermal conductivity, corrosion resistance, durability, and cost-effectiveness.

Send your message to us

AA1050 CC Prepainted Aluminum Roofing Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords