030 Aluminum Coil - Aluminium Coated Coils for Cladding System and Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

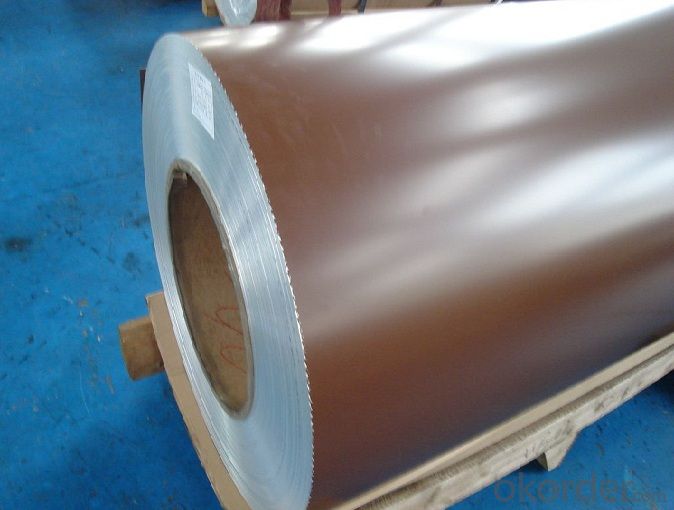

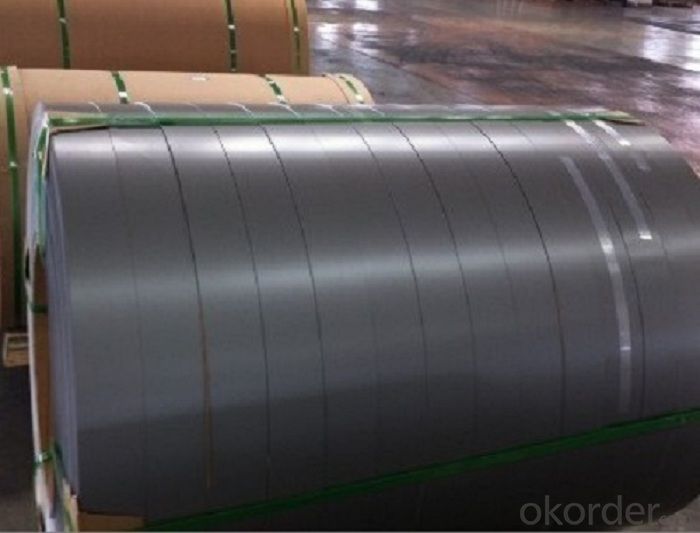

Aluminium Coated Coils for Cladding System and Roofing

l Product Information

| Alloy | 1050 1060 1100 3003 3004 3005 5005 8011 etc |

| Temper | H12, H14, H16, H18, H24, H26 |

| Thickness | 0.02mm - 1.2mm |

| Width | Standard width: 1240mm |

| Special width: 1300mm,1520mm,1570mm,1595mm | |

| Diameter | Standard dia:1200mm |

| Interior dia:150mm,405mm,505mm | |

| Weight | 2.5 T/coils, 3.0 T/coil |

| Coating | PE, PVDF,ACRYLIC |

| Surface | Embossed, mill finish, coated |

| Color | As to code RAL |

| Gloss | 10-90% (EN ISO-2813:1994) |

| Coating Thickness | PE:more than 18 micron |

| PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

| Coating Adhesion | 5J(en iso-2409:1994) |

| Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

| Flexibility (T-bend) | 2T |

| MEK resistance | more than 100 |

| Advantage | 1.High temperature resistant 2.Weathering resistance 3.Scrubbing resistant 4.Sound insulation 5.Acid or alkali proof 6. Fireproof 7.Light weight material is easy to construct and install |

| Out package | wooden splint with export standard |

| Application | ACP,wall cladding, facades, roofs and canopies, ceilings, signboards, blind window, display platforms, electrical panels , etc |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received original L/C or advance payments

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: How are aluminum coils cleaned and maintained?

- Regular cleaning is essential for maintaining the optimal performance and efficiency of aluminum coils, which are commonly used in HVAC systems and refrigeration units. Here's a step-by-step guide on how to clean and maintain them: 1. Prioritize safety: Before starting the cleaning process, ensure that the power to the HVAC system or refrigeration unit is switched off to prevent accidents. 2. Remove debris: Begin by getting rid of any visible debris like leaves, dirt, or dust from the aluminum coils. Use a soft brush or a vacuum cleaner with a brush attachment to gently eliminate the debris. 3. Apply a cleaning solution: Create a cleaning solution by mixing water with a mild detergent or coil cleaner. Follow the instructions on the product label to achieve the proper dilution ratio. Transfer the solution to a spray bottle. 4. Use the cleaning solution: Spray the cleaning solution onto the aluminum coils, ensuring that all areas are covered. Allow the solution to sit for a few minutes to loosen any dirt or grime. 5. Gently scrub the coils: Use a soft brush or a coil cleaning brush to gently scrub the aluminum coils. Take care not to apply excessive pressure, as it may damage the delicate fins on the coils. Concentrate on areas with stubborn dirt or buildup. 6. Rinse with water: After scrubbing, thoroughly rinse the aluminum coils with clean water. You can use a hose or a pressure washer on a low setting to ensure that all the cleaning solution and dirt are removed. Make sure that the water flows in the opposite direction of the airflow to prevent pushing debris further into the coils. 7. Inspect for damage: While cleaning, inspect the aluminum coils for any signs of damage, such as bent fins or leaks. If you notice any issues, it is advisable to contact a professional technician for repairs. 8. Allow for complete drying: Once rinsed, allow the aluminum coils to air dry completely before turning the power back on. This will prevent any moisture-related problems and ensure that the coils are ready for use. 9. Maintain a regular cleaning schedule: To keep the aluminum coils in excellent condition, it is crucial to establish a regular cleaning schedule. Generally, cleaning every three to six months is recommended, depending on usage and environmental factors. However, if the coils are located in a highly polluted or dusty area, more frequent cleaning may be necessary. By following these steps and adhering to a regular cleaning schedule, you can ensure that your aluminum coils remain clean, efficient, and in optimal working condition.

- Q: What are the different types of aluminum alloys used for making coils?

- There are various types of aluminum alloys used for making coils, including 1100, 3003, 5052, and 6061. These alloys differ in terms of their composition and properties, such as strength, corrosion resistance, and formability, allowing manufacturers to select the most suitable alloy based on the specific requirements of the application.

- Q: Is it possible to use aluminum coils for decorative purposes in a garden setting?

- <p>Yes, aluminum coils can be used for decoration in the garden. They are lightweight, durable, and resistant to corrosion, making them suitable for outdoor use. You can form them into various shapes or use them to create unique garden structures such as trellises, sculptures, or even as part of a fence. Their metallic finish can add a modern or industrial touch to your garden's aesthetic, and they can be painted or left in their natural state to blend with different garden themes.</p>

- Q: What is the minimum thickness available for aluminum coils?

- The minimum thickness available for aluminum coils can vary depending on the specific requirements of the application. However, in general, aluminum coils can be manufactured with a minimum thickness of around 0.006 inches or 0.15 millimeters. It is important to note that certain industries or uses may have different minimum thickness requirements, so it is always advisable to consult with a manufacturer or supplier to determine the appropriate thickness for a specific application.

- Q: I have found many articles claiming that the aluminum content in soy (baby) formula is very high.What I am wondering is- does regular old soy milk for adult consumption also have very high aluminum content?I am extensively researching all possible ways to relieve my 14 month olds terrible constipation. He is not allergic to milk- he was on a milk-based formula. We VERY slowly switched over to whole cow's milk- which turned out to once again be terribly constipating. It was suggested I give lactose-free milk a try- which has seemed to help a little bit- it was working OK for a few days- but he did have quit the hard (and painful) bowel movement a couple days ago. We are trying other options- juices, he's active, we are trying to get enough fiber into this picky eater's diet. I am just researching the possibility of soy milk if this problem persists.I am not willing to give it to him if the aluminum content is even a small possibility. I am not finding much info about adult soy milk. Anyone??

- Soy is known to have a lot of hormones in it. Not good for a growing baby. A study even showed that female infants that were fed soy formula went into puberty a lot sooner than girls that were fed breastmilk or regular formula.

- Q: What are the different alloys used for aluminum coils?

- There are several different alloys used for aluminum coils, each with its own unique properties and applications. Some of the commonly used alloys include: 1. 1100 Alloy: This is a commercially pure aluminum alloy with excellent corrosion resistance and high thermal conductivity. It is often used in applications where high thermal or electrical conductivity is required, such as in heat exchangers or electrical conductors. 2. 3003 Alloy: This alloy is a general-purpose aluminum alloy that offers good resistance to atmospheric corrosion and moderate strength. It is commonly used in applications where moderate strength and formability are required, such as in packaging, roofing, or vehicle parts. 3. 5052 Alloy: This alloy is one of the highest strength non-heat-treatable aluminum alloys. It offers excellent corrosion resistance and good formability. It is often used in marine applications, as well as in automotive parts and appliances. 4. 6061 Alloy: This alloy is a heat-treatable aluminum alloy with excellent strength and corrosion resistance. It is often used in structural applications, such as in aircraft components, marine hardware, or bicycle frames. 5. 7075 Alloy: This alloy is a high-strength aluminum alloy with excellent fatigue strength. It is commonly used in aerospace and military applications, as well as in high-stress structural parts. These are just a few examples of the many alloys used for aluminum coils. The specific alloy chosen will depend on the desired properties and intended application of the coil.

- Q: Can aluminum coils be used in high-altitude environments?

- Yes, aluminum coils can be used in high-altitude environments. Aluminum is a lightweight and corrosion-resistant material, making it suitable for various applications, including in high-altitude environments. Aluminum coils are commonly used in air conditioning systems, heat exchangers, and refrigeration units, which can function efficiently at high altitudes. Aluminum's high strength-to-weight ratio allows it to withstand the extreme conditions found at high altitudes, including low temperatures, high winds, and low atmospheric pressure. Additionally, aluminum is non-magnetic, which is advantageous in certain high-altitude applications, such as aerospace and satellite technologies. Furthermore, aluminum has excellent thermal conductivity, allowing it to efficiently transfer heat, making it ideal for use in cooling systems operating in high-altitude environments. Its corrosion resistance properties also make it durable and able to withstand the effects of moisture, which can be prevalent in such environments. Overall, aluminum coils are a reliable and suitable choice for use in high-altitude environments due to their lightweight, corrosion resistance, thermal conductivity, and strength.

- Q: Can aluminum coils be used for roofing?

- Yes, aluminum coils can be used for roofing. Aluminum is a popular choice for roofing materials due to its durability, lightweight nature, and resistance to corrosion. Aluminum roofing coils are frequently used in various types of roofs, including residential, commercial, and industrial buildings. They offer excellent protection against extreme weather conditions, such as heavy rain, snow, and high winds. Additionally, aluminum coils are energy-efficient as they can reflect heat from the sun, helping to keep the building cool and reducing energy costs. Overall, aluminum coils provide a reliable and long-lasting roofing solution.

- Q: what is the hardness number of aluminium.....? what is the hardness number of aluminium-Sic composite material...?

- I don't believe that Aluminum (US spelling)/ Aluminium (UK spelling) has a Mohs Hardness rating. The Hardness of a material, as measured by the Mohs Hardness scale, is a criterion of its resistance to crushing. [Perry's Chemical Engineering Handbook]. Since aluminum is a metal, and would deform under a crushing-type stress, rather than shatter, it would not have a Mohs Hardness rating. Perhaps you meant **aluminA**, rather than aluminum. Alumina (Al2O3) has a Modified Mohs Hardness of 12. Silicon Carbide (carborundum) has a Modified Mohs Hardness of 13. There's no value listed for the combination, but it should be pretty hard stuff -- likely in the 12-13 range, but potentially even harder. Hope that helps.

- Q: This question asks for methods to prevent corrosion on aluminum coils during storage or transportation.

- <p>To prevent corrosion on aluminum coils during storage or transportation, follow these steps: 1. Store the coils in a dry, clean environment to avoid moisture and dirt. 2. Use protective wrapping or covers to shield the coils from moisture and contaminants. 3. Ensure proper ventilation in storage areas to prevent condensation. 4. Avoid stacking coils directly on the ground; use pallets or racks to keep them off damp surfaces. 5. Handle the coils carefully to prevent scratches or damage that could lead to corrosion. 6. Regularly inspect the coils for signs of corrosion and address any issues promptly. 7. Consider using anti-corrosion coatings or treatments on the coils if they will be stored for extended periods. By following these guidelines, you can minimize the risk of corrosion and maintain the integrity of your aluminum coils.</p>

Send your message to us

030 Aluminum Coil - Aluminium Coated Coils for Cladding System and Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords