1060 Aluminum Coil Gutter Roof Aluminium Coil PE PVDF Color Coated Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Gutter Roof Aluminium Coil PE PVDF Color Coated Coil

l Product Introduction

Aluminium Coil is widely used in manufacturing aluminum thin sheet and aluminum foil. It is suitable for further machining with original standard quality. It is easy to be controlled and be manufactured to according to requirements.

l Product Specification

| Aluminum Alloy: | AA1100, 1050, 1060, 3003, 3004, 3005, 3103, 3105, 5005, 5052, 5083, 5754, 6061, 8011 |

| Temper: | O, H16, H18, H22, H24, H26, H28 |

| Aluminum Alloy Thickness: | 0.08mm~1.2mm(0.08, 0.18, 0.28, 0.38, 0.48, 0.6, 0.8, 1 mm) |

| (0.1, 0.15, 0.25, 0.35, 0.45 mm) | |

| Coil Width: | 30~1520mm china price color coated aluminium coil |

| Core Diameter: | 150/ 405/ 505mm |

| Coil Weight: | 1~2.5 tons each coil for 3003 colorful aluminium coil for acp |

| Coating Type: | PE, PVDF, back coatting, ACRYLIC, feve |

| Surface Type: | Smooth, Embossed, Mill finish, Coated, Brushed, etc. |

| Glossness: | 10-90%(EN ISO-2813:1994) |

| Coating Thickness: | PE: more than 18 +-1micron |

| PVDF: more than 25+-1micron | |

| Back Coating: 8~10+-1micron | |

| Coating Color: | Color A: pure white, ivory, white matte, yellow white, opal, light gray, aluminum natural color etc. |

| Color B: blue, yellow, gray, black, dark gray etc. | |

| Color C: white silver gray, flash silver, champagne etc. | |

| Color D: violet, pure orange, orange, bright red, china red, dark blue, brown, green, laker blue, flash gold yellow etc. | |

| Paint Hardness: | More than 2H |

| Coating Adhesion: | 5J(EN ISO-2409:1994) |

| Impact Resistance: | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

| Advantage: | 1.High temperature resistant 3003 colorful aluminium coil for acp |

| 2.Weathering resistant | |

| 3.Scrubbing resistant | |

| 4.Sound insulation | |

| 5.Acid or alkali proof,Fireproof | |

| 6.Light weight material is easy to construct and install | |

| Packing Details: | Five-layer carton, strong polar fumigation wooden pallet, steel belt fastened outside,worthy shipping by sea. |

| Coating Aluminum Standard: | Chemical Composite:GB/T 3190-2008,JIS,EN,ASTM,Mechanical Property: GB/T 3880-2006, ASTM |

| Application: | acp, aluminum composite panel, roof, gutter, ceiling, facade, wall cladding, gutter,aluminum honeycomb panel,roller shutter, rolling shutter, truck body, rolling shutter door, etc. |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advanced payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium coil is one of the popular product in the market of CNBM. With advanced technology and equipment, CNBM has sold its hight quality color coated aluminium coil to the world.

l CNBM World Wide

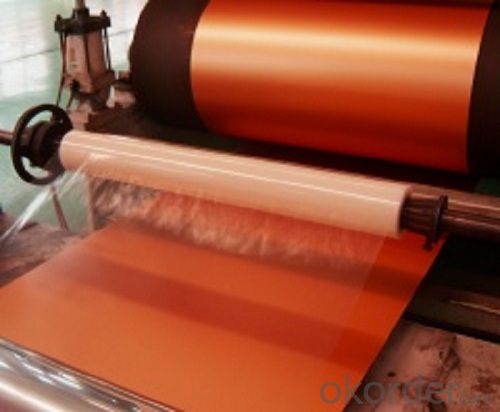

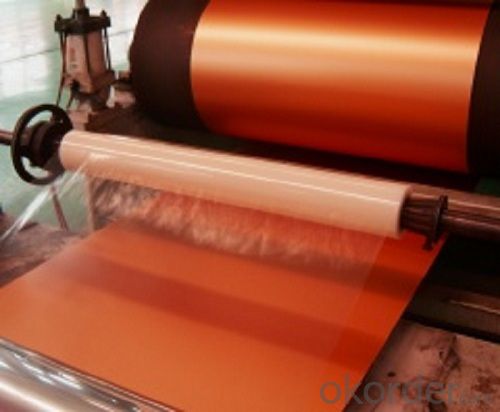

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: What are the potential applications of laminated aluminum coils?

- Laminated aluminum coils have a wide range of potential applications. They can be used in industries such as electrical, automotive, aerospace, and construction. Some specific applications include electrical transformers, heat exchangers, automotive radiators, air conditioning systems, and architectural facades. The lamination process enhances the durability, heat and corrosion resistance, and electrical conductivity of the coils, making them suitable for various demanding environments and applications.

- Q: Can aluminum coils be used in the production of automotive body panels?

- Yes, aluminum coils can be used in the production of automotive body panels. Aluminum is a lightweight and highly malleable material, making it an ideal choice for automotive applications. It offers a good balance between strength and weight, which can help improve fuel efficiency and overall vehicle performance. Additionally, aluminum has excellent corrosion resistance properties, which is crucial for automotive body panels exposed to harsh environmental conditions. The use of aluminum coils in the production of automotive body panels has become increasingly popular as automakers strive to reduce the weight of vehicles and improve their sustainability.

- Q: How much does it cost to use fluorocarbon paint for aluminum coil roller coating?

- Fluorocarbon paint can be divided into fluorocarbon paint for exterior wall, aluminum fluorocarbon paint, metal fluorocarbon paint and steel structure fluorocarbon paint according to usages. It can also be divided into national standard product and non-national standard product according to industrial standards.

- Q: My favorite deodorant contains aluminum. It smells really good and it works really well.My mom doesn't like me using it because it contains aluminum.So I got aluminum free. It doesn't smell at all (I can't seem to find fragrant aluminum free deodorant) and it doesn't work as well, for some reason.I want to keep using the one with aluminum, but will it be harmful to me in the future?

- i have tom deo. and it is totally safe, it is all organic stuff that you could like grow in your backyard. As apposed to chemical junk. kudoos to you for stopping with the anti-perspirants

- Q: How much is one square aluminum gate and five hard door?

- Double layer aluminum alloy, in the middle of the 5 bars, ordinary white or beige is 215, a square, the motor, in addition, the general 600KG copper core motor has 550 sets, there are 680 sets. On the Alibaba website search "roll gate", there are many manufacturers, you can ask them.

- Q: What is the impact resistance of aluminum coils?

- The impact resistance of aluminum coils is generally high. Aluminum has a good strength-to-weight ratio and is known for its ability to withstand impact and deformation without breaking or fracturing easily. This makes aluminum coils suitable for various applications where resistance to impacts and mechanical stress is important, such as in construction, automotive, and aerospace industries.

- Q: Can aluminum coils be used in roofing or cladding systems?

- Yes, aluminum coils can be used in roofing or cladding systems. Aluminum is a popular choice for these applications due to its lightweight nature and excellent corrosion resistance. Aluminum coils are commonly used in roofing and cladding systems to create a durable and long-lasting solution. They are often coated with a protective layer or finish to enhance their performance and aesthetics. Additionally, aluminum coils are easy to work with, making installation and maintenance convenient. Overall, aluminum coils are a suitable choice for roofing or cladding systems as they offer various advantages and meet the requirements of these applications.

- Q: actually pollute more than the process of extracting it from earth and producing new aluminum?I saw a report about 5 years ago on this and was wondering if anyone else had info on this subject.

- There is a significant savings - especially in electricity - about 90% less energy used to recycle aluminum than it takes to smelt ore and process it into useable aluminum.

- Q: What are the different coil winding methods for aluminum coils?

- There are several coil winding methods for aluminum coils, including hand winding, machine winding, and automated winding. Hand winding is a manual process where the wire is carefully wrapped around the coil by hand. Machine winding involves using a winding machine that automatically wraps the wire around the coil, increasing efficiency and accuracy. Automated winding takes it a step further by utilizing robotic arms or other automated systems to wind the coils, providing even greater precision and speed.

- Q: Are aluminum coils suitable for decorative purposes?

- <p>Yes, aluminum coils can be used for decoration. They are lightweight, durable, and corrosion-resistant, making them ideal for various decorative applications. Aluminum coils can be shaped and colored to suit different design needs, often used in architectural features, interior design elements, and even in art installations. Their versatility and aesthetic appeal make them a popular choice for both commercial and residential decoration.</p>

Send your message to us

1060 Aluminum Coil Gutter Roof Aluminium Coil PE PVDF Color Coated Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords