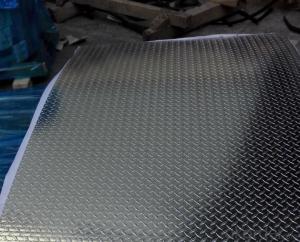

0.7 mm Thick Embossed Aluminum Zinc Roofing Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of 0.7 mm Thick Embossed Aluminum Zinc Roofing Sheet

Alloy | Temper | Specification(mm) | ||||

Thickness | Width | Length | Embossing Depth | Surface Treatment | ||

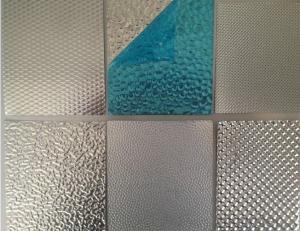

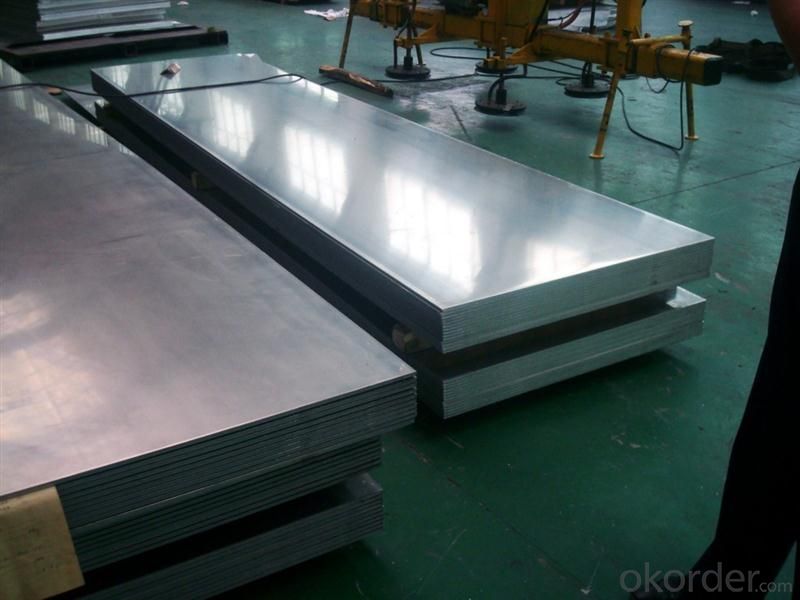

1050, 1060, 1100, 1070, 3003, 3105, etc. | O, H12, H14, H16, H18, H22, H24, H26, H32, etc. | 0.25~2.0 | ≤1250 | As per customer’s | 0.08~0.25 | Mill Finish, Bright Finish, Anodized, Color Coated |

Tolerance | ||||||

Thickness (base materials) | Thickness | Embossing Depth | Width | Length | Diagonal | |

0.25~0.5 | 0~0.05 | +/- 0.01 | +/-0.5 | +/- 1.0 | +/- 1.5 | |

> 0.5~2.0 | 0~0.10 | +/- 0.02 | +/-1.0 | +/- 1.5 | +/- 2 | |

We can produce as per customers’ special requirements. | ||||||

Chemical composition 0.7 mm Thick Embossed Aluminum Zinc Roofing Sheet

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Other | Min Al/ % | ||

Single | Total | ||||||||||||

3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | - | - | - | 0.10 | - | - | 0.05 | 0.15 | Remain |

3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | 0.15 | - | 0.25 | - | - | 0.05 | 0.15 | Remain |

FAQ

--Q: Do you provide free samples?

--A: Yes, free samples will be sent to you on freight at destination.

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

--Q: What kinds of alloy can you supply?

--A: 1000 series: 1050, 1060, 1070, 1100, 1145, 1200

3000 series: 3003, 3004, 3105, 3104

5000 series: 5052, 5083, 5754, 5182

6000 series: 6061, 6063, 6062, 6063

8000 series: 8011, 8021

--Q: What kinds of temper can you supply?

--A: O-H112: O,H12,H14,H16,H18,H22,H24,H26,H,32,H34,H111,H112

T3, T4, T6

- Q: Can aluminum sheets be bent or formed without cracking or breaking?

- Yes, aluminum sheets can be bent or formed without cracking or breaking, but it depends on the thickness of the sheet and the method used for bending or forming. Aluminum is a highly malleable metal, which means it can be easily bent or formed into various shapes without breaking. However, if the sheet is too thin or the bending or forming process is done without proper care or precision, there is a risk of cracking or breaking. To avoid this, it is important to use appropriate tools and techniques, such as using a bending brake or a rolling machine, and ensuring that the sheet is not subjected to excessive force or stress during the process. Additionally, annealing the aluminum sheet before bending or forming can increase its flexibility and reduce the chance of cracking. Overall, with the right approach and precautions, aluminum sheets can be successfully bent or formed without cracking or breaking.

- Q: Should I purchase a camper made out of aluminum/wood or a fiberglass?I'm looking to purchase a small camper, approx 18', to tow on the back of my SUV. It's a 2011 Wildwood camper. However, I hear campers made out of aluminum and wood aren't very good because the wood can ruin in time and the aluminum can rust, etc. I hear fiberglass campers are better? Anyone have any knowledge or experience with this? Also, any thoughts or advice with brands/models? And about the Wildwood? Thanks in advance.

- Aluminum is lighter so it offers economies over the life of the trailer. The Airstream has been built almost as long as I've been around. It is true that the wood does rot And some care is needed to stop the occasional leak. Fiberglass is heaver and has it's own maintenance issues. I've no experience with the Wildwood. What I do know is that motor homes are dirt cheap right now. You might think about taking advantage of the economy and pick-up a motor home at a bargain.

- Q: Would you please tell me what putty to use on the aluminium board, what kind of putty, and the painting process?

- Applied atomic ash.Consider adding an interface agent, that is, applying an interfacial agent on the aluminum plate, and then applying a topcoat on the interface agent after drying.You can also consider adding primer or putty, and then spray paint.In summary, adhesion of the topcoat is reinforced with an agent.

- Q: So I got this stainless steel ring but I took it to this place and apparently its not stainless it's aliminum bc of how light it is but it's really hard so how could it be aluminum?

- Aluminum is a quite soft metal, but so is gold. It is true that aluminum is light in weight but magnesium is even lighter and is common enough that a ring could be made of it. Metals can be made harder by adding small amounts of other metals or even by the way it is heat treated. .

- Q: Can aluminum sheets be used for industrial shelving?

- Yes, aluminum sheets can be used for industrial shelving. Aluminum is a lightweight and durable material that offers several advantages for industrial shelving applications. It is resistant to corrosion, which makes it suitable for environments that are exposed to moisture or harsh chemicals. Aluminum's strength-to-weight ratio is also advantageous, as it allows for the construction of sturdy shelves that can hold heavy loads while remaining relatively lightweight. Additionally, aluminum is easy to maintain, as it does not require painting or sealing like other metals. Overall, aluminum sheets are a practical choice for industrial shelving due to their durability, corrosion resistance, and lightweight properties.

- Q: What are the common thicknesses of aluminum sheets used in transportation industry?

- Aluminum sheets are widely utilized in the transportation sector for various purposes due to their lightweight, durability, and ability to resist corrosion. In this industry, the thickness of aluminum sheets typically falls within the range of 0.025 inches (0.63 mm) to 0.125 inches (3.18 mm). When it comes to automotive body panels, which necessitate a balance between weight reduction and structural integrity, the preferred thickness of aluminum sheets is usually between 0.040 inches (1.02 mm) and 0.063 inches (1.6 mm). These particular thicknesses ensure sufficient strength while effectively reducing the overall weight of the vehicle compared to steel counterparts. In the aerospace field, where weight reduction is of utmost importance, thinner aluminum sheets are commonly employed. Typically, thicknesses ranging from 0.025 inches (0.63 mm) to 0.040 inches (1.02 mm) are used in the construction of aircraft structures, including wings, fuselage panels, and interior components. It is important to note that the specific thicknesses of aluminum sheets in the transportation industry may vary depending on the particular application, regulatory requirements, and design factors. Thus, it is crucial to consult the relevant industry standards and specifications for accurate information regarding the recommended thicknesses for different transportation applications.

- Q: What is aluminum sheet material L2?

- L2 is the name of the brand of aluminium plate in our country, which is the 1060 brand now!L1 is 1070L2 is 1060L3 is 1050L4 is 1030L5-1 is 1100And LF-21, or 3003, LF-1, or 3004! Wait

- Q: What is the fatigue life of aluminum sheets?

- The endurance capacity of aluminum sheets pertains to the number of cycles the material can endure before failure arises under cyclic loading circumstances. Various factors, including the composition, thickness, surface finish, loading conditions, and environmental elements, can cause the endurance capacity of aluminum sheets to differ. Aluminum is renowned for its relatively high fatigue strength in comparison to other materials, rendering it a favored option in industries like aerospace, automotive, and construction. The endurance capacity of aluminum sheets is typically influenced by the presence of microstructural flaws, such as inclusions, voids, and grain boundaries. Fatigue tests are conducted, utilizing standardized procedures like ASTM E466 or ASTM E606, to ascertain the endurance capacity of aluminum sheets. These tests entail subjecting the material to cyclic loading conditions, usually at a consistent stress or strain amplitude, while monitoring the number of cycles required for failure to arise. The outcomes are then employed to generate an S-N curve, which represents the connection between the applied stress or strain amplitude and the number of cycles until failure. The S-N curve furnishes valuable insights into the endurance capacity of aluminum sheets, indicating the stress or strain levels at which the material can withstand a specific number of cycles before failure. It is crucial to note that the endurance capacity of aluminum sheets can be enhanced through various approaches, such as alloying, heat treatment, surface treatment, and appropriate design considerations. To conclude, the endurance capacity of aluminum sheets plays a pivotal role in the design of components or structures exposed to cyclic loading conditions. By comprehending the specific properties and characteristics of the aluminum alloy, coupled with proper testing and analysis, it is possible to ascertain the endurance capacity and guarantee the safe and dependable performance of aluminum sheets in diverse applications.

- Q: According to the reactivity of metals, aluminum chloride (AlCl3) will not react with copper (Cu). But I am almost sure that the copper nail I put in the aluminum chloride solution became shiny and lost its copper lust. Why did this reaction happen?

- Well done on noting unexpected observations and following up. Your copper is coated with a dull coating of copper oxide. It became shiny because aluminium salts are acidic in water and the acidity dissolves the coating to form a copper salt and leaving the shiny copper. CuO + 2H3O+ ---- Cu2+ + 3H2O The reaction to form the acidity, a hydrated hydrogen ion H+(H2O) or H3O+ is fairly complex. If aluminium chloride is dissolved in a large amount of water the solution is acidic, but this has nothing to do with formation of hydrochloric acid. The solution contains hydrated aluminium ions and chloride ions: AlCl3(s) + aq → [Al(H2O)6]3+(aq) + 3Cl -(aq) The hexaqua complex ion behaves exactly like ions of similar type formed from transition metals; the small, highly charged metal ion polarises (withdraws electron density from) the water molecules that are attached to the aluminium ion through dative covalent bonds. This makes the hydrogen atoms d+ and susceptible to attack from solvent water, which is acting as a base. The complex ion is deprotonated, causing the solution to be acidic from the formation of hydroxonium ions H3O+: [Al(H2O)6]3+(aq) + H2O(l) → [Al(H2O)5OH]2+(aq) + H3O+(aq)

- Q: What are the different manufacturing methods for aluminum sheets?

- Aluminum sheets can be manufactured using various methods, each possessing its own unique characteristics and applications. 1. Rolling, the most commonly employed method, involves passing large aluminum slabs through a series of rollers to reduce thickness and increase length. This process ensures consistent thickness and excellent surface finish. 2. Another method, extrusion, utilizes a heated aluminum billet forced through a die, resulting in a continuous sheet. Extrusion allows for the creation of complex shapes and profiles, making it suitable for applications in building construction and automotive components. 3. Casting involves pouring molten aluminum into a mold, allowing it to cool and solidify into a sheet shape. This method is often used for producing thicker sheets or those with specific alloy compositions. Casting offers unique properties and is prevalent in industries such as aerospace and defense. 4. Cladding entails bonding a thin layer of aluminum to another material like steel or composite materials. This combines the desirable qualities of aluminum, such as corrosion resistance and lightweight, with the strength and durability of the base material. Clad aluminum sheets find common use in construction, transportation, and electrical industries. 5. Powder metallurgy involves forming aluminum sheets from powdered aluminum particles. The powder is compacted into the desired shape and then sintered at high temperatures to fuse the particles together. This method is ideal for producing complex shapes and can improve mechanical properties. Considering the desired properties, application, and cost considerations, it is crucial to select the most appropriate manufacturing method for aluminum sheets based on the specific project requirements.

Send your message to us

0.7 mm Thick Embossed Aluminum Zinc Roofing Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords