0.17-1.20mm Prime PPGI and GI Roofing Sheet in Coil Sample Avilabale for Free

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 50000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

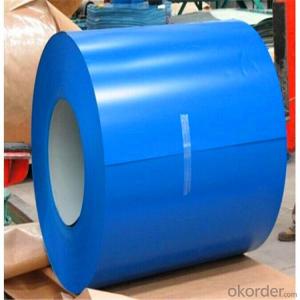

0.17-1.20mm Prime PPGI and GI Roofing Sheet in Coil Sample Avilabale for Free

Description of 0.17-1.20mm Prime PPGI and GI Roofing Sheet in Coil

Product | PPGI/PPGL |

Capacity | 5,000 tons/month |

Base material | Hot dipped galvanized steel |

Thickness | 0.2-2.0mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | SGCC, DX51D |

Color | RAL No. or customers samples’ color |

Zinc-coating | 30g/m2-180g/m2 |

Coil ID | 508mm/610mm |

Technique | Cold rolled—hot dipped galvanized—color coated |

Painting | Top painting:15~25μm |

Back painting: 6~10μm | |

Tolerance | Thickness: +/-0.02mm |

Width:+/-2mm | |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

Application of 0.17-1.20mm Prime PPGI and GI Roofing Sheet in Coil

APPLICATION OF OUR PREPAINTED STEEL | ||||||||||

Construction | Outside | Workshop,agricultural warehouse,residential precast unit | ||||||||

corrugated roof,roller shutter door,rainwater drainage pipe,retailer booth | ||||||||||

Inside | Door,doorcase,light steel roof stucture,folding screen,elevator,stairway,ven gutter,Construction Wall | |||||||||

Electrical applicance | Refrigerator,washer,switch cabnet,instrument cabinet,air conditioning,micro-wave owen,bread maker | |||||||||

Fuiniture | Central heating slice,lampshade,chifforobe,desk,bed,locker,bookself | |||||||||

Carrying trade | Exterior decoration of auto and train,clapboard,container,isolation lairage,isolation board | |||||||||

Qthers | Writing panel,garbagecan,billboard,timekeeper,typewriter,instrument panel,weight sensor,photographic equipment | |||||||||

Products Show of 0.17-1.20mm Prime PPGI and GI Roofing Sheet in Coil

Product Advantages

1.With nearly 20 years experience in prepainted steel, accommodate different marketdemands. | ||||||||||||||

2.'Quality first, service first' is our business aim; 'The good faith get respect,cast quality market' is our Business philosophy . | ||||||||||||||

3.Having two series producttion line,with the abbual production capacity of 240000 tons. | ||||||||||||||

4.Exceed International ISO9001:2008&ISO14001:2004 quality and environmental standards | ||||||||||||||

5.Meet with ROHS standard |

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the different surface treatment methods for special steel?

- Some of the different surface treatment methods for special steel include heat treatment, coating or plating, polishing, shot blasting, and passivation. Heat treatment involves subjecting the steel to specific temperatures and cooling processes to alter its properties. Coating or plating involves applying a layer of another material, such as zinc or chrome, to protect the steel from corrosion. Polishing is done to create a smooth and glossy surface finish. Shot blasting is a process that involves using abrasive materials to remove impurities and create a textured surface. Passivation is a chemical treatment used to remove iron contaminants and improve corrosion resistance. These methods can be utilized individually or in combination to enhance the surface characteristics of special steel.

- Q: Can special steel be used for luxury goods?

- Yes, special steel can be used for luxury goods. Special steel, often known for its exceptional quality, durability, and unique aesthetic appeal, can be utilized in the production of high-end luxury goods such as watches, jewelry, and accessories. Its premium attributes and distinct characteristics make it an attractive choice for luxury brands seeking to craft exclusive and sophisticated products that cater to discerning customers.

- Q: What are the environmental impacts of producing special steel?

- The production of special steel can have several environmental impacts. Firstly, the extraction of raw materials, such as iron ore and coal, can lead to habitat destruction and soil erosion. Additionally, the energy-intensive processes involved in steel production, such as smelting and refining, contribute to greenhouse gas emissions, air pollution, and climate change. Moreover, the disposal of waste materials, including slag and dust, can contaminate water sources and harm aquatic life. It is crucial to implement sustainable practices and technologies to mitigate these environmental impacts and ensure responsible steel production.

- Q: What are the different methods for improving the electrical conductivity of special steel?

- There are several methods for improving the electrical conductivity of special steel. One common method is through the addition of alloying elements such as copper or silver. These elements can help to increase the number of free electrons in the steel, thereby improving its electrical conductivity. Another method is by subjecting the steel to heat treatment processes such as annealing or normalizing. These heat treatments can help to refine the microstructure of the steel, reducing the presence of impurities and enhancing the movement of electrons. Surface treatments, such as electroplating or coating the steel with a conductive material like copper or nickel, can also improve its electrical conductivity. These treatments create a conductive layer on the surface of the steel, enabling better electron flow. Additionally, refining the grain size of the steel through processes like grain boundary engineering or severe plastic deformation can improve its electrical conductivity. Smaller grain sizes allow for more efficient electron movement and reduce scattering, leading to enhanced conductivity. Lastly, proper cleaning and removal of any surface contaminants or oxides can significantly improve the electrical conductivity of special steel. By removing impurities and ensuring a clean surface, the steel can have better contact and conductivity. It is important to note that the specific method used to improve the electrical conductivity of special steel will depend on the intended application and the desired level of conductivity. Different industries and applications may require different approaches to achieve the desired results.

- Q: How is special steel recycled?

- Special steel is typically recycled through a process called electric arc furnace (EAF) steelmaking. In this process, scrap steel is collected and melted down in an electric arc furnace, where high temperatures are used to separate impurities. Once the impurities are removed, the molten steel is then refined and cast into new forms to create various specialized steel products, ensuring that the steel is effectively recycled and reused.

- Q: How does special steel perform in terms of weldability?

- Special steel generally performs well in terms of weldability. It is specifically designed to have good weldability characteristics, which means it can be easily welded without much difficulty or the need for specialized welding techniques. This makes it a preferred choice for many welding applications, as it allows for efficient and reliable joining of different components or structures.

- Q: How is special steel used in the packaging industry?

- Special steel is widely used in the packaging industry for its exceptional strength, durability, and corrosion resistance properties. It is commonly utilized to manufacture packaging materials such as cans, containers, and closures. Special steel ensures the safety and integrity of products during storage and transportation, while also allowing for efficient and cost-effective packaging solutions.

- Q: How does special steel contribute to the hardness of products?

- The hardness of products is enhanced by special steel due to its distinct composition and manufacturing techniques. Unlike regular steel, special steel is mixed with additional elements like chromium, nickel, and manganese, which bolster its strength and durability. These alloying elements combine with the steel matrix to form solid solutions, resulting in a more rigid and compact structure. The inclusion of these alloying elements in special steel allows for the creation of diverse microstructures, including fine-grained structures and martensitic structures, which significantly increase the steel's hardness. Moreover, special steel often undergoes heat treatment processes such as quenching and tempering, which further refine its microstructure and enhance its hardness. Furthermore, the hardness of special steel can also be influenced by the manufacturing processes employed, such as hot rolling or cold working. These processes deform the steel, align its grain structure, and minimize any defects or impurities, resulting in a more uniform and harder material. The hardness of special steel plays a vital role in various industries where strength, wear resistance, and resistance to deformation are crucial. For instance, in the automotive industry, special steel is utilized in the production of engine parts, gears, and axles, all of which require high hardness to withstand challenging conditions and loads. Similarly, in the construction industry, special steel is used for manufacturing tools, cutting blades, and reinforcement bars, where hardness is essential for longevity and performance. In conclusion, special steel's contribution to product hardness is attributed to its unique alloying elements, manufacturing techniques, and heat treatments. Its ability to form various microstructures and its resistance to deformation make it an excellent material for applications where hardness is vital for performance and durability.

- Q: Is special steel recyclable?

- Yes, special steel is recyclable.

- Q: What are the challenges faced in the manufacturing process of special steel?

- To ensure the production of high-quality special steel, numerous challenges must be addressed in the manufacturing process. Some of the key challenges faced are as follows: 1. Raw material selection: It is crucial to choose the appropriate raw materials with specific alloying elements in precise proportions to achieve the desired properties of special steels. Consistently ensuring the availability and quality of these raw materials can be challenging. 2. Alloy design and composition: Designing the alloy composition to meet specific requirements can be a complex task. Achieving the desired balance of strength, hardness, toughness, corrosion resistance, and other properties necessitates thorough research, testing, and expertise. Developing new alloys with improved properties can be particularly difficult. 3. Melting and refining: Special steels are typically produced using electric arc furnaces or induction melting. Ensuring precise temperature control, proper cooling rates, and refining processes to eliminate impurities like sulfur, phosphorus, and non-metallic inclusions are crucial. Advanced technology and precise control are necessary to maintain consistent quality. 4. Heat treatment: Heat treatment is a critical step in the special steel manufacturing process. Achieving the desired microstructure and properties through processes like quenching, tempering, annealing, or precipitation hardening can be challenging. Proper temperature control, heating and cooling rates, and time durations are essential to obtain the desired properties. 5. Quality control and testing: Consistently ensuring quality throughout the manufacturing process is of utmost importance. Regular testing and inspection to detect and eliminate defects, inconsistencies, and non-conformities are necessary. This includes dimensional accuracy, mechanical properties testing, non-destructive testing, and chemical analysis. 6. Production efficiency: Special steel manufacturing often involves complex procedures and longer processing times compared to regular steel production. Optimizing the production process to maximize efficiency, minimize waste, and reduce energy consumption is an ongoing challenge. Implementing lean manufacturing principles and utilizing advanced technologies can help address these challenges. 7. Environmental considerations: The production of special steel can have a significant environmental impact. Addressing issues such as energy consumption, waste management, emissions control, and water usage is crucial for sustainable production. Complying with environmental regulations and adopting eco-friendly practices can be challenging yet necessary. Overcoming these challenges requires a combination of technical expertise, research and development, investment in advanced equipment and technologies, and an ongoing commitment to quality control and process improvement.

Send your message to us

0.17-1.20mm Prime PPGI and GI Roofing Sheet in Coil Sample Avilabale for Free

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 50000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords