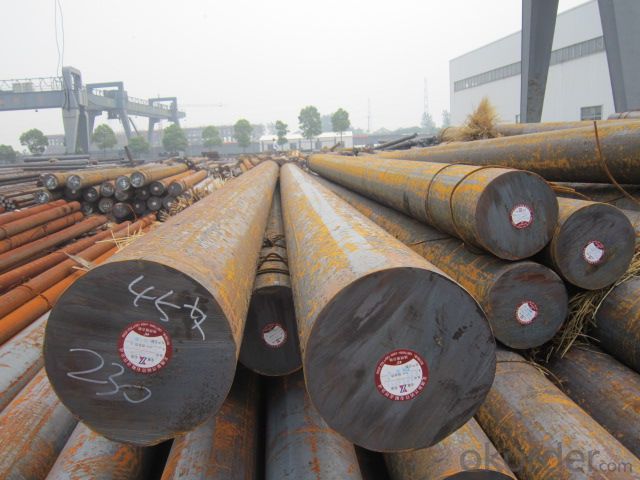

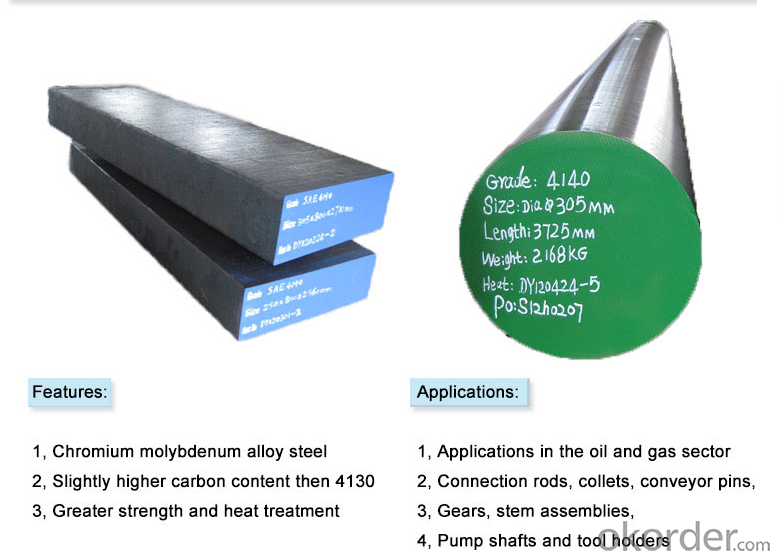

AISI 4140 Carbon Alloy Steel Round Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

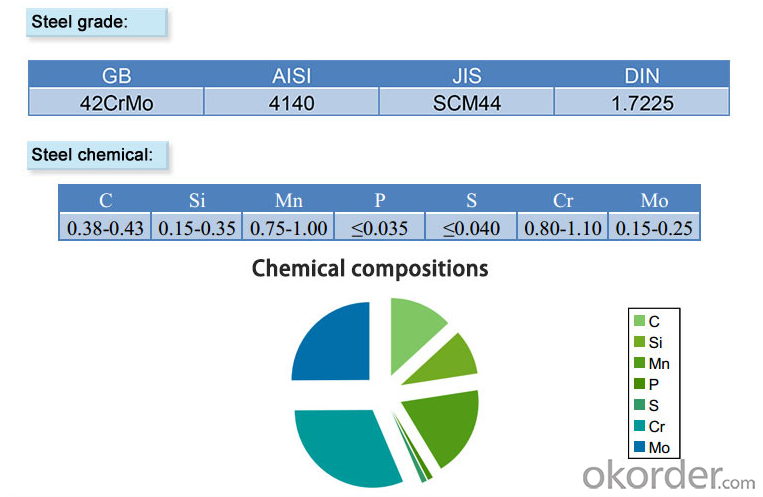

AISI 4140 Carbon Alloy Steel Round Bars

Product information:

- High Quanlity

-Various Type and Specification

-Competetive Price

- Perfect Service

-On Time Delivery

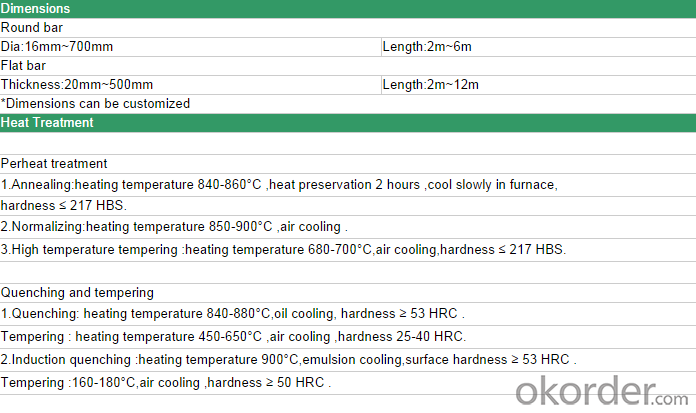

2.Process: EAF + LF + VD + Forged + Heat Treatment (optional)

3.Delivery condition: Hot forged +Rough machined (black surface after Q/T)+ Turned (optional)

4.Technical Data: According to the customer's requirement of Chemical Composition, Physical Properties and Mechanical Testing

5.Test: ultrasonic test according to SEP 1921-84 3 D/D

6.Material details will be as per agreed technical specifications

Other product show:

Our workshop show:

Our service:

-High manufacturing accuracy

-High strength

-Small inertia resistance

-Strong heat dissipation ability

-Good visual effect

-Reasonable price

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer's trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you need the sample, please feel free to let me know. Any question, we will contact you ASAP!

- Q: How does high-speed steel perform in high-temperature cutting operations?

- High-speed steel performs exceptionally well in high-temperature cutting operations. It has excellent heat resistance, retaining its hardness and strength even at elevated temperatures. This makes it highly effective in applications that involve high cutting speeds and temperatures, ensuring prolonged tool life and improved cutting performance.

- Q: What are the different methods for improving the creep resistance of special steel?

- Several methods exist to enhance the creep resistance of special steel. One commonly employed technique involves alloying. By incorporating specific alloying elements like chromium, molybdenum, and vanadium, the steel's creep resistance can be significantly improved. These alloying elements create stable carbides or nitrides that serve as obstacles to dislocation movement, thereby reducing the rate of creep deformation. Heat treatment represents another effective approach. By subjecting the steel to carefully controlled heating and cooling processes, the microstructure can be refined to enhance its creep resistance. Techniques such as quenching and tempering aid in the formation of a fine-grained structure, which in turn increases the steel's strength and resistance to creep. Surface modification offers an alternative means of improving creep resistance. Nitriding and carburizing techniques can be utilized to introduce nitrogen or carbon into the steel's surface layer, creating a hardened layer that enhances creep resistance. Moreover, grain size control can be achieved through methods like grain boundary engineering or severe plastic deformation. By refining the grain structure, the movement of dislocations within the material is impeded, resulting in improved creep resistance. Lastly, the application of coatings can also bolster the creep resistance of special steel. Coatings such as ceramic or metallic coatings provide a protective layer that hampers the diffusion of impurities and slows down the creep rate. To summarize, the improvement of creep resistance in special steel can be accomplished through various techniques, including alloying, heat treatment, surface modification, grain size control, and the use of coatings. These methods aim to fortify the steel's microstructure, hinder dislocation movement, and establish protective barriers against creep deformation.

- Q: What are the main advantages of using special steel in the automotive industry?

- Special steel has several main advantages in the automotive industry. Firstly, it offers increased strength and durability, allowing for lighter weight components without compromising safety. This not only improves fuel efficiency but also enhances overall vehicle performance. Secondly, special steel has excellent corrosion resistance, ensuring a longer lifespan and reducing maintenance costs. Lastly, its versatility enables the production of complex shapes and designs, enabling manufacturers to create innovative and efficient automotive structures.

- Q: How does special steel perform in food processing applications?

- Special steel performs exceptionally well in food processing applications. Its unique properties such as high corrosion resistance, heat resistance, and hygienic surface finish make it ideal for use in equipment and machinery that come into direct contact with food. Special steel's resistance to chemicals and bacteria growth ensures that the food processing environment remains safe and contamination-free. Additionally, its durability and strength allow for efficient and reliable operation, contributing to the overall effectiveness of food processing operations.

- Q: How does special steel perform in high-temperature oxidation resistance?

- Special steel is specifically designed to have excellent high-temperature oxidation resistance. This type of steel contains alloying elements such as chromium, aluminum, and silicon, which form a protective oxide layer on the surface when exposed to high temperatures. This oxide layer acts as a barrier, preventing further oxidation and corrosion of the steel. The high-temperature oxidation resistance of special steel is crucial in applications where the material is exposed to extreme heat and oxidation, such as in gas turbines, heat exchangers, and furnaces. The protective oxide layer helps to maintain the integrity and strength of the steel, even under harsh conditions. Furthermore, special steel also exhibits excellent creep resistance at high temperatures. Creep refers to the gradual deformation of a material under a constant load and elevated temperatures. The unique composition of special steel provides it with the ability to resist creep deformation, enhancing its overall performance and reliability in high-temperature environments. In conclusion, special steel performs exceptionally well in high-temperature oxidation resistance due to its alloying elements and the formation of a protective oxide layer. Its ability to resist oxidation and maintain its structural integrity at elevated temperatures makes it a preferred choice for various industrial applications.

- Q: How is special steel stored and transported?

- To maintain the quality and integrity of special steel, it is handled with utmost care during storage and transportation. During storage, the steel is kept in a controlled environment with the right temperature and humidity levels to prevent corrosion and damage. Covered warehouses and storage facilities specifically designed for steel are used to shield it from rain, snow, and sunlight. When it comes to transportation, different methods are employed depending on the quantity and distance. For short distances, smaller amounts of steel are transported using trucks equipped with flatbeds or enclosed trailers. These trucks are designed to securely hold and protect the steel, ensuring it does not shift or get damaged during transit. However, for longer distances or larger quantities, rail or sea transportation is preferred. Rail transportation offers a smooth and stable journey, minimizing the risk of damage caused by vibrations or sudden movements. Specially designed railcars are used to securely store and protect the steel during transit. Sea transportation involves loading the steel onto shipping containers or specialized vessels. Containers are sealed and secured to prevent any movement or damage during the journey. Specialized vessels, such as roll-on/roll-off ships or heavy-lift vessels, are used for oversized or extremely heavy steel components. In all cases, special steel is carefully packaged and secured using appropriate materials like wooden crates, steel strapping, or plastic wrapping to prevent scratches or dents. The transportation process is closely monitored, and necessary precautions are taken to ensure the steel reaches its destination in optimal condition. Overall, the storage and transportation of special steel require thorough planning, proper handling, and the use of specialized equipment to safeguard its quality and protect it from potential damage or degradation.

- Q: What are the different production methods for special steel?

- Special steel can be produced using various methods, each with its unique advantages and characteristics. Some commonly used methods include: 1. Electric Arc Furnace (EAF): Scrap steel is melted in an electric arc furnace, where intense heat generated by an electric current melts the materials. EAF is known for its flexibility, as it can produce a wide range of steel grades and alloys. 2. Basic Oxygen Furnace (BOF): Molten iron from a blast furnace is combined with scrap steel and oxygen in this process to remove impurities and adjust the carbon content. BOF is famous for its high production capacity and the ability to produce large quantities of steel. 3. Vacuum Induction Melting (VIM): VIM is a method employed to produce high-quality and high-purity steel. It involves melting the raw materials in a vacuum environment to prevent contamination and achieve precise control over the alloy composition. 4. Continuous Casting: Molten steel is poured into a water-cooled mold in this method, which continuously produces solidified steel slabs, blooms, or billets. Continuous casting is efficient and capable of producing consistent and defect-free steel products. 5. Powder Metallurgy: Metal powders are compacted and sintered to produce steel with specific properties in this technique. Powder metallurgy enables the production of complex shapes, improved mechanical properties, and the incorporation of challenging-to-achieve alloying elements through traditional methods. 6. Additive Manufacturing (AM): AM, also known as 3D printing, is a relatively new method for producing special steel. It involves layer-by-layer deposition of metal powders, which are then fused together using heat or a laser. AM offers design freedom, the capability to produce complex geometries, and the potential for customized steel parts. Each production method possesses its advantages and limitations, and the selection depends on factors such as desired steel properties, production volume, cost considerations, and the specific requirements of the end-use application.

- Q: What are the different methods of surface passivation for special steel?

- Surface passivation methods for special steel vary in order to enhance its corrosion resistance and overall performance. One popular approach is chemical passivation, where a protective coating is applied to the steel's surface. This coating, composed of substances like chromium oxide or nitric acid, is typically formed through a chemical reaction that creates a protective layer. Chemical passivation is commonly used in industries where the steel is exposed to corrosive environments, such as marine or chemical applications. Another method is mechanical passivation, which involves physically altering the steel's surface to create a protective barrier. This can be achieved through techniques like shot peening or sandblasting, which create a roughened surface that is less prone to corrosion. Mechanical passivation is often employed in situations where the steel is exposed to abrasive or erosive conditions, such as mining or oil drilling. Electrochemical passivation is yet another technique used to passivate special steel surfaces. It entails using an electric current to generate a protective oxide layer on the steel's surface. Processes like electrochemical polishing or anodizing achieve this controlled oxidation. Electrochemical passivation is frequently utilized in industries where the steel is subjected to high temperatures or aggressive chemical environments. Additionally, specialized surface treatments, like plasma or laser surface passivation, are available for special steel. These methods utilize concentrated energy sources to modify the steel's surface and create a protective layer that enhances its corrosion resistance and mechanical properties. Such treatments are typically applied in high-performance applications, such as the aerospace or automotive industries. Ultimately, the choice of surface passivation method for special steel depends on the specific requirements of the application and the desired performance characteristics of the material. Each method has its own advantages and limitations, and factors like cost, time, and environmental impact should be considered when selecting the most suitable method for a particular application.

- Q: What are the different methods of strengthening special steel?

- Special steel can be strengthened in various ways, each with its own benefits and uses. Heat treatment is a common method, involving heating the steel to a specific temperature and then cooling it rapidly or slowly, depending on the desired result. This can involve processes such as quenching, tempering, and annealing, which change the steel's microstructure to enhance its mechanical properties. Another method is alloying, where different elements are added to the steel to improve its strength. For instance, adding elements like chromium, nickel, or molybdenum can enhance the steel's resistance to corrosion, while vanadium or tungsten can increase its hardness and wear resistance. Cold working is another technique used to strengthen special steel, involving deforming the steel at room temperature through rolling, forging, or drawing. This aligns the steel's crystalline structure, boosting its strength and hardness. Moreover, surface treatments can be employed to enhance the strength of special steel. Techniques like carburizing, nitriding, or plating can introduce a hardened layer or coating on the steel's surface, improving its wear resistance and durability. Each method has its own advantages and can be customized to meet specific requirements and applications. By combining different strengthening techniques, special steel can be tailored to fulfill a wide range of industrial needs, making it a reliable and versatile material.

- Q: What are the applications of high-speed steel?

- High-speed steel has various applications due to its exceptional properties. It is commonly used in the manufacturing of cutting tools such as drills, saw blades, milling cutters, and taps. Its high hardness and heat resistance make it suitable for machining operations on materials like steel, cast iron, and non-ferrous alloys. Additionally, high-speed steel is also used in the production of power tool bits, punches, and dies, where its wear resistance and toughness are advantageous.

Send your message to us

AISI 4140 Carbon Alloy Steel Round Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords